- Joined

- Sep 28, 2002

- Messages

- 39,793

Originally Posted By: friendly_jacek

Originally Posted By: BuickGN

Yep, oil pressure before the filter will go up but with the positive displacement oil pump, flow will be the same.

Remember, there is a bypass there too whether it's on the engine or in the filter.

Don't assume that better filtration means less flow. This may be true of the conventional cellulose filters but not the synthetic media Amsoil and Royal Purple filters.

Not quite. Higher pressure before filter will force more oil to bypass valve after the oil pump and less to the bearings.

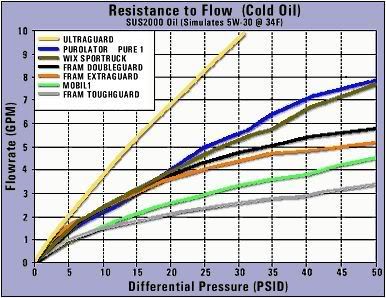

Mobil 1 and PureOne are more restrictive. There are many studies that document that. Not sure Amsoil, but possible.

Yes, 'quite'. Everyone somehow thinks that the pressure on the other side of the filter is substantially lower. It's not.

No one has the slightest inkling of "back pressure" that make the filter mostly invisible under all but a few conditions. It's beyond comprehension for most. This is very difficult to convey.

Originally Posted By: BuickGN

Yep, oil pressure before the filter will go up but with the positive displacement oil pump, flow will be the same.

Remember, there is a bypass there too whether it's on the engine or in the filter.

Don't assume that better filtration means less flow. This may be true of the conventional cellulose filters but not the synthetic media Amsoil and Royal Purple filters.

Not quite. Higher pressure before filter will force more oil to bypass valve after the oil pump and less to the bearings.

Mobil 1 and PureOne are more restrictive. There are many studies that document that. Not sure Amsoil, but possible.

Yes, 'quite'. Everyone somehow thinks that the pressure on the other side of the filter is substantially lower. It's not.

No one has the slightest inkling of "back pressure" that make the filter mostly invisible under all but a few conditions. It's beyond comprehension for most. This is very difficult to convey.