Just FYI, it may not be the springs causing the increase in ride height. I replaced the struts, upper mounts and spring isolator rubbers on my 328, and it increased front ride height a full inch. Now it rides at the proper ride height.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Strut spring compressor questions

- Thread starter LeakySeals

- Start date

- Status

- Not open for further replies.

Yes, assuming no user error. Battery charged? High output or just regular XC? No extensions? Reverse mode?Then something I wasn't expecting happened. Figured I would use my beloved Milwaukee half inch impact to loosen up the tool on the spring I removed quicker. It was hammering not turning. I couldn't believe it. So then I put my hand on the ratchet. I could make it hammer and stop just holding on to it. How could that be!!!! "1400 pounds of nut busting power" and I'm holding it in place with my hand. That's depressing. Paid a lot of money for that thought it would be the last one I ever owned. I guess there's something wrong with it. It should have twisted my arm off right?

Thanks for the encouragement. I cranked the spring down a lot and it still didn't separate. Rather than stress the tool anymore I decided to give the top fastener a zip with the Milwaukee. Back it off just a little bit and see what happens. Not quite enough so I tightened a little bit more and then I was good. Now that I know how much to tighten it the rest should be a breeze.

Then something I wasn't expecting happened. Figured I would use my beloved Milwaukee half inch impact to loosen up the tool on the spring I removed quicker. It was hammering not turning. I couldn't believe it. So then I put my hand on the ratchet. I could make it hammer and stop just holding on to it. How could that be!!!! "1400 pounds of nut busting power" and I'm holding it in place with my hand. That's depressing. Paid a lot of money for that thought it would be the last one I ever owned. I guess there's something wrong with it. It should have twisted my arm off right?

It sounds like a dud tool to me. Let us know how it goes with their CS and warranty. How long have you had it, it may still be returnable.

LeakySeals

Thread starter

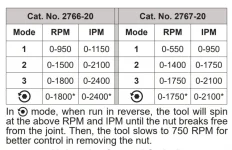

I've only had it on the 4th setting. Which is max power until It breaks free and then it slows RPM to 750. I played with it this morning and I can't hold it back on the 3rd setting which is max power no sensors. It's down one bar on the battery. So I'm not thinking that should have an effect on it. But at least I can use it for today. I like the slowing down feature. That's great for lug nuts. Going to try contacting them MondayIt sounds like a dud tool to me. Let us know how it goes with their CS and warranty. How long have you had it, it may still be returnable.

Attachments

Charge up the battery. May just be a bad battery. Try another one too.I've only had it on the 4th setting. Which is max power until It breaks free and then it slows RPM to 750. I played with it this morning and I can't hold it back on the 3rd setting which is max power no sensors. It's down one bar on the battery. So I'm not thinking that should have an effect on it. But at least I can use it for today. I like the slowing down feature. That's great for lug nuts. Going to try contacting them Monday

There is nothing wrong with your impact wrench. These wrenches can't work against a spring. In this case, your hand is functioning as a spring.Yes, assuming no user error. Battery charged? High output or just regular XC? No extensions? Reverse mode?

This principal is used in torque sticks. The torque stick becomes a "spring" at a chosen torque value and adsorbs further impacts, limiting tightening lug nuts beyond that value. Problem is that ppl continue to run up air pressure past that point and the torque stick "spring" stops being a spring (can't adsorb anymore), defeating its purpose, and acts like a solid extension, grossly overtightening the lug nuts.

LeakySeals

Thread starter

Thank you for the explanation. So it's possible a deep socket or an extension could do the same thing. I'm letting the battery go all the way down in hopes that will help. Get a complete charge which it's never had in the two years I've owned itThere is nothing wrong with your impact wrench. These wrenches can't work against a spring. In this case, your hand is functioning as a spring.

This principal is used in torque sticks. The torque stick becomes a "spring" at a chosen torque value and adsorbs further impacts, limiting tightening lug nuts beyond that value. Problem is that ppl continue to run up air pressure past that point and the torque stick "spring" stops being a spring (can't adsorb anymore), defeating its purpose, and acts like a solid extension, grossly overtightening the lug nuts.

"These wrenches can't work against a spring." Huh? I must be missing something.

I've used corded impact wrenches on spring compressors and "touch-touch-touch" is all that's required.

The springs don't need to go far to free the top plate.

I've used corded impact wrenches on spring compressors and "touch-touch-touch" is all that's required.

The springs don't need to go far to free the top plate.

AutoMechanic

Site Donor 2025

I’ve never used power or air tools on spring compressors I was told it wasn’t recommended so I have always used a big ratchet and socket lol.

Brap brap brap brap ZING!I’ve never used power or air tools on spring compressors I was told it wasn’t recommended so I have always used a big ratchet and socket lol.

Then something I wasn't expecting happened. Figured I would use my beloved Milwaukee half inch impact to loosen up the tool on the spring I removed quicker. It was hammering not turning. I couldn't believe it. So then I put my hand on the ratchet. I could make it hammer and stop just holding on to it. How could that be!!!! "1400 pounds of nut busting power" and I'm holding it in place with my hand. That's depressing. Paid a lot of money for that thought it would be the last one I ever owned. I guess there's something wrong with it. It should have twisted my arm off right?

It's quite easy to stop an impact gun with your hands. It needs to be, as the torque put on the nut is leveraged against you holding the tool. The fastening power comes from the repeated hammering. Use a drill on those nuts and they WILL twist your arm off, even with something like 30 ftlbs.

You certainly are. The nut holding the spring compressor plate down is not a spring. As far as the impact wrench is concerned, it does not "see" anything past the socket it is attached to."These wrenches can't work against a spring." Huh? I must be missing something.

I've used corded impact wrenches on spring compressors and "touch-touch-touch" is all that's required.

The springs don't need to go far to free the top plate.

LeakySeals

Thread starter

It does seem like it's not sensing when to go full power and then slow down when it's loosemight be the smart mode doesnt work in that application.

try it on regular high mode?

I believe you can easily overpower the spring compressor with the power tool and then once that happens, the spring breaks loose and hopefully doesn't kill anyone.I’ve never used power or air tools on spring compressors I was told it wasn’t recommended so I have always used a big ratchet and socket lol.

AutoMechanic

Site Donor 2025

True. We had one guy using the spring compressor on the wall at work once he broke the spring compressor and shot the old spring up and luckily their was no one else in the shop since the customer was paying for him to stay late to expedite the repair and it bounced right into their car let’s just say they got a big refund for that repair LOL.I believe you can easily overpower the spring compressor with the power tool and then once that happens, the spring breaks loose and hopefully doesn't kill anyone.

LeakySeals

Thread starter

I did not use the impact to tighten the spring compressor. But I did use it to loosen up the compressor after the spring was safely fastened behind the seat. I did snug the top mounting nut with the impact on low rather than find a way to prevent the piston from spinning. I didn't let it hammer longer than a second, whatever tight that was is how tight the bearings are. I was able to move the top mount during installation to line up the studs. Tight, but it moved by hand.

Was easy the second time around when I knew what to expect. Swapped back to the old springs in an hour. The rear sags so I'm going to replace the rear springs which are not part of a strut. Should I wait for alignment till after that?

Was easy the second time around when I knew what to expect. Swapped back to the old springs in an hour. The rear sags so I'm going to replace the rear springs which are not part of a strut. Should I wait for alignment till after that?

I would wait, as long as you can bang out the rears in a week or less. A little driving won't hurt, I just wouldn't drive it thousands of miles on brand new expensive tires in the mean time.I did not use the impact to tighten the spring compressor. But I did use it to loosen up the compressor after the spring was safely fastened behind the seat. I did snug the top mounting nut with the impact on low rather than find a way to prevent the piston from spinning. I didn't let it hammer longer than a second, whatever tight that was is how tight the bearings are. I was able to move the top mount during installation to line up the studs. Tight, but it moved by hand.

Was easy the second time around when I knew what to expect. Swapped back to the old springs in an hour. The rear sags so I'm going to replace the rear springs which are not part of a strut. Should I wait for alignment till after that?

LeakySeals

Thread starter

Thanks. The rear springs are here so I'll be doing them over the weekend. Need to touch them up with something so they don't rust. They were beating on each other inside the box.I would wait, as long as you can bang out the rears in a week or less. A little driving won't hurt, I just wouldn't drive it thousands of miles on brand new expensive tires in the mean time.

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 4

- Views

- 408

- Replies

- 5

- Views

- 195

- Replies

- 25

- Views

- 571