You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Run central AC unit on generator

- Thread starter oldcodger

- Start date

gathermewool

Site Donor 2023

Anybody installed a Micro-Air EasyStart device on their whole house AC unit? It cuts down and manages the initial inrush current that the compressor needs. With it installed you can run the AC system using a generator.

Where do you live, how big is your house, and how often would you need to run the whole house AC? For me in New England, even on the hottest days during the summer I wouldn’t consider running more than a window unit on a generator. That’s a lot of gas.

Also, depending on how many tons your AC unit is and how efficient it is, a relatively large generator is required. My 2kW inverter can actually run my 10kBTU window unit, but it bogs heavily when the compressor initially engages A 2.5 ton unit? Not possible. The 5K units, which is all I’d use for our main bedroom during an emergency, is no problem.

This unit costs more than a small AC unit.

AZjeff

$50 Site Donor 2023

I put a M/A EasyStart on the RV AC unit and it works as advertised. I can start and run the 15k BTU AC with a 2500W generator.

They make a good product.

They make a good product.

Looks like a soft start and their website says it supports up to 6 tons. As long as you don't have a variable speed compressor it's should work just fine.

A whole home ac is still going to use a ton of power even steady stat so you'll need to make sure your generator is large enough for that. You'll need the new starting amps from the comp with the soft start and the starting amps for both the condenser and air handler fans.

A whole home ac is still going to use a ton of power even steady stat so you'll need to make sure your generator is large enough for that. You'll need the new starting amps from the comp with the soft start and the starting amps for both the condenser and air handler fans.

I can see a use case for having one of these "EasyStart" type of things (isn't it just a large start capacitor?) even if you are never going to run it on a generator.

You'll need the new starting amps from the comp with the soft start and the starting amps for both the condenser and air handler fans.

You can turn on the fan first if you want to. Most HVAC fans have an "auto" and an "on" setting. My reasoning being that if you can turn it on first, you avoid the combined 3 motor inrush current.

May not be needed if the gen is large enough. My 6500W (a 7500 hooked to NG) starts my 3 ton fine. My HVAC systems are completely split upstairs/downstairs though, so your unit may be larger than a 3 ton.Anybody installed a Micro-Air EasyStart device on their whole house AC unit? It cuts down and manages the initial inrush current that the compressor needs. With it installed you can run the AC system using a generator.

Can't you just use a large capacitor?

That's more or less a hard start without the disconnect relay. They don't actually lower the current needed just the amount of time that current is needed for.Can't you just use a large capacitor?

That's more or less a hard start without the disconnect relay. They don't actually lower the current needed just the amount of time that current is needed for.

Hummmm...maybe I don't understand electrical demand and power the way I thought I did...engineering school was a long time ago.

My understanding is that it would take a "surge power" to get a compressor going. That is a power calculation, not a current calculation. So, when taking a surge demand like that, obviously voltage drops, and puts an even higher demand on current to supply the needed power to get something going. Now, if I were to install a capacitor, my understanding is that the overall power demand to get the compressor going remains about the same, but it helps to distribute that power requirement over a longer period of time. If overall power requirements remains pretty much the same, but the input to the capacitor is double or even tripled, then my understanding is that the instantaneous current demand should be cut by half or more, reducing the demand on the generator.

Now, I am just a mechanical engineer that specializes in hydraulics, but that is how it would work for a pump supplying flow with an installed accumulator in line to a high demand application. Maybe my logic is flawed?

I’m a bit rusty on electrical knowledge too, but I would also think that a much larger capacitor would accomplish the same thing. The power requirement for startup remains the same regardless, if the capacitor is able to feed the voltage for a longer period and prevent voltage drop, that will reduce the current requirement.

Same here, our 8kW standby generator starts the 3-ton unit okay. It’s not on the emergency circuit so I have to run a jumper between the panels if it’s summer and we have a power outage.May not be needed if the gen is large enough. My 6500W (a 7500 hooked to NG) starts my 3 ton fine. My HVAC systems are completely split upstairs/downstairs though, so your unit may be larger than a 3 ton.

So this is actually a bit more complex of a topic and I simplified a bit in my previous post. You can read a few posts at HVAC school here that explain it better than I but be sure to read all 4 posts. It also has pretty graphs. But the basics are this:Hummmm...maybe I don't understand electrical demand and power the way I thought I did...engineering school was a long time ago.

My understanding is that it would take a "surge power" to get a compressor going. That is a power calculation, not a current calculation. So, when taking a surge demand like that, obviously voltage drops, and puts an even higher demand on current to supply the needed power to get something going. Now, if I were to install a capacitor, my understanding is that the overall power demand to get the compressor going remains about the same, but it helps to distribute that power requirement over a longer period of time. If overall power requirements remains pretty much the same, but the input to the capacitor is double or even tripled, then my understanding is that the instantaneous current demand should be cut by half or more, reducing the demand on the generator.

Now, I am just a mechanical engineer that specializes in hydraulics, but that is how it would work for a pump supplying flow with an installed accumulator in line to a high demand application. Maybe my logic is flawed?

Hard start: Large capacitor that decreases the amount of time the compressor is coming up to speed by increasing the instantaneous torque of the motor. This doesn't decrease the instantaneous power required but decreases the total power over time because the compressor motor will spend less time in its more inefficient startup phase. This means it doesn't require less power at any moment to startup but spends less time starting so it spends less power total. You still have the 7-15 times running current required to start the motor you can just deliver it quicker

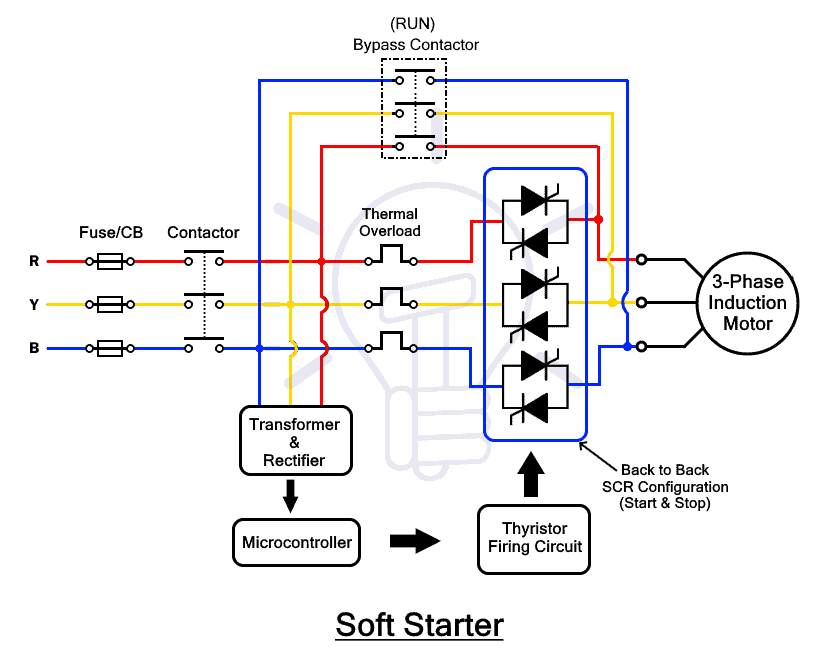

Soft start: Basically the opposite. These carefully regulate the voltage into the compressor matching it to the load slowly bringing the motor up to speed. This leaves the motor in the "run" phase at all times completely side stepping the inrush current needed to start the motor.

- Joined

- Jul 11, 2014

- Messages

- 4,118

My 6-10kw generators have no problem with the whole house hvac and don't need any easystarters. They also power the well waterpump, electric hot water heater, and a couple fridges and freezers.

I see where it would help those that don't size their generators with AC btu/tonnage correctly.

I see where it would help those that don't size their generators with AC btu/tonnage correctly.

So this is actually a bit more complex of a topic and I simplified a bit in my previous post. You can read a few posts at HVAC school here that explain it better than I but be sure to read all 4 posts. It also has pretty graphs. But the basics are this:

Hard start: Large capacitor that decreases the amount of time the compressor is coming up to speed by increasing the instantaneous torque of the motor. This doesn't decrease the instantaneous power required but decreases the total power over time because the compressor motor will spend less time in its more inefficient startup phase. This means it doesn't require less power at any moment to startup but spends less time starting so it spends less power total. You still have the 7-15 times running current required to start the motor you can just deliver it quicker

Soft start: Basically the opposite. These carefully regulate the voltage into the compressor matching it to the load slowly bringing the motor up to speed. This leaves the motor in the "run" phase at all times completely side stepping the inrush current needed to start the motor.

Again, maybe you can help me...the statement you quoted...

Hard start: Large capacitor that decreases the amount of time the compressor is coming up to speed by increasing the instantaneous torque of the motor. This doesn't decrease the instantaneous power required but decreases the total power over time because the compressor motor will spend less time in its more inefficient startup phase. This means it doesn't require less power at any moment to startup but spends less time starting so it spends less power total. You still have the 7-15 times running current required to start the motor you can just deliver it quicker

That is what I was trying to explain. The instantaneous power is not changed...and must be supplied, but if it can be supplied by a large capacitor, and "load leveled" then it is a much easier load to drive from the generator or grid perspective.

While I am not a EE, I did dabble in competitive car stereo, and home audio where instantaneous power requirements are huge, but can be made palatable to the system by using capacitors.

The power to start is the same...if you can use a buffer (capacitor) to ease the shock to the system, it can be more easily powered.

gathermewool

Site Donor 2023

So this is actually a bit more complex of a topic and I simplified a bit in my previous post. You can read a few posts at HVAC school here that explain it better than I but be sure to read all 4 posts. It also has pretty graphs. But the basics are this:

Hard start: Large capacitor that decreases the amount of time the compressor is coming up to speed by increasing the instantaneous torque of the motor. This doesn't decrease the instantaneous power required but decreases the total power over time because the compressor motor will spend less time in its more inefficient startup phase. This means it doesn't require less power at any moment to startup but spends less time starting so it spends less power total. You still have the 7-15 times running current required to start the motor you can just deliver it quicker

Soft start: Basically the opposite. These carefully regulate the voltage into the compressor matching it to the load slowly bringing the motor up to speed. This leaves the motor in the "run" phase at all times completely side stepping the inrush current needed to start the motor.

voltage and frequency can be varied for soft starts.

A cap can simply be seen as a voltage stabilize/damper.

Yes I suppose it depends on how close to the limits the generator is. The generator will still see the full power requirements needed by the compressor to start it just won't be as long. A "large" capacitor for this use is about 300mfd not near enough to make it invisible to the generator.Again, maybe you can help me...the statement you quoted...

Hard start: Large capacitor that decreases the amount of time the compressor is coming up to speed by increasing the instantaneous torque of the motor. This doesn't decrease the instantaneous power required but decreases the total power over time because the compressor motor will spend less time in its more inefficient startup phase. This means it doesn't require less power at any moment to startup but spends less time starting so it spends less power total. You still have the 7-15 times running current required to start the motor you can just deliver it quicker

That is what I was trying to explain. The instantaneous power is not changed...and must be supplied, but if it can be supplied by a large capacitor, and "load leveled" then it is a much easier load to drive from the generator or grid perspective.

While I am not a EE, I did dabble in competitive car stereo, and home audio where instantaneous power requirements are huge, but can be made palatable to the system by using capacitors.

The power to start is the same...if you can use a buffer (capacitor) to ease the shock to the system, it can be more easily powered.

You could make a capacitor bank large enough though but it'd be easier to just use a soft start and alot safer.

Never heard of soft starters before, but the above simply didn’t make sense to me. Limiting voltage makes absolutely no sense. The winding would not produce the necessary electromagnetic field for the motor to start. I read up on it quickly and most articles say similar things, so I don’t blame you for repeating what they say.So this is actually a bit more complex of a topic and I simplified a bit in my previous post. You can read a few posts at HVAC school here that explain it better than I but be sure to read all 4 posts. It also has pretty graphs. But the basics are this:

Hard start: Large capacitor that decreases the amount of time the compressor is coming up to speed by increasing the instantaneous torque of the motor. This doesn't decrease the instantaneous power required but decreases the total power over time because the compressor motor will spend less time in its more inefficient startup phase. This means it doesn't require less power at any moment to startup but spends less time starting so it spends less power total. You still have the 7-15 times running current required to start the motor you can just deliver it quicker

Soft start: Basically the opposite. These carefully regulate the voltage into the compressor matching it to the load slowly bringing the motor up to speed. This leaves the motor in the "run" phase at all times completely side stepping the inrush current needed to start the motor.

However, after more digging these soft starters use current limiting rectifiers. Now that makes more sense. You limit the current and slowly increase it. Sort of like slowly opening a water tap, vs quickly.

A larger capacitor will take that initial brunt, so in the end the result will be similar IMO. Not and EE though, so I might be missing something.

Yes the solid state ones do use Thyristors to ramp the voltage up gradually. They do this by controlling the firing angle of the thyristors. combine this with ohms law and you have an easy way to control current. They don't directly act on the current.Never heard of soft starters before, but the above simply didn’t make sense to me. Limiting voltage makes absolutely no sense. The winding would not produce the necessary electromagnetic field for the motor to start. I read up on it quickly and most articles say similar things, so I don’t blame you for repeating what they say.

However, after more digging these soft starters use current limiting rectifiers. Now that makes more sense. You limit the current and slowly increase it. Sort of like slowly opening a water tap, vs quickly.

A larger capacitor will take that initial brunt, so in the end the result will be similar IMO. Not and EE though, so I might be missing something.

What is Soft Starter? Its Working, Diagram and Applications

Motor Starter. Soft Starter Circuit Diagram. Working Principle of Soft Starter. Advantages & Disadvantages of Motor Starter Applications of Soft Starter

Only if you are using a VFD in a soft start role. A basic soft start is based on thyristors and does not act on the frequency.voltage and frequency can be varied for soft starts.

A cap can simply be seen as a voltage stabilize/damper.

Similar threads

- Replies

- 57

- Views

- 3K

- Replies

- 56

- Views

- 3K

- Replies

- 50

- Views

- 2K