Are you running it in ECO mode, if so does it do the same thing in Normal mode.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need Help with a Small Engine

- Thread starter NETWizz

- Start date

I'm not sure you're looking at that correctly.. or at least one of us isn't#7 in the parts diagram from @grasscutter is the pilot screw and appears adjustable. And yes, this is where I would start at first. Quarter turn out at a time.

Otherwise it will be something to do with adjusting that throttle motor. That may be a recipe for endless adjustment disaster, as in you'll never get it right or be satisfied unless it runs really smooth. And in that case, just live with it. It's going to run under load most of the time anyway.

It's listed as a pilot jet and most that I have seen like that are a fixed orifice. If it were adjustable, I would expect to see a needle right near the throttle plate.

- Joined

- Feb 6, 2025

- Messages

- 54

#7 might be a screw covering the pilot jet like on my Honda carburetor. If you look back at the picture, the limiter cap is partially blocking the view of a Phillips screw which is a cover for a 0.35mm hole. I call it a pilot jet but I really don't know what it is. It's definitely a hole with a special purpose that's not removable and uses a Phillips screw as a man-hole cover.#7 in the parts diagram from @grasscutter is the pilot screw and appears adjustable. And yes, this is where I would start at first. Quarter turn out at a time.

Otherwise it will be something to do with adjusting that throttle motor. That may be a recipe for endless adjustment disaster, as in you'll never get it right or be satisfied unless it runs really smooth. And in that case, just live with it. It's going to run under load most of the time anyway.

Last edited:

Without knowing the manufacturer of this carburetor, it could be both. As in the pilot orifice is fixed underneath the screw and the screw itself trims the pilot/idle mix.I'm not sure you're looking at that correctly.. or at least one of us isn't

It's listed as a pilot jet and most that I have seen like that are a fixed orifice. If it were adjustable, I would expect to see a needle right near the throttle plate.

The Keihins have a separate pilot (slow speed) jet/orifice (0.35 most GCV engines) and provides overall fuel for that circuit. The final trim is handled by the screw with the limiter cap on it, as it controls how much air is drawn across the idle/pilot/slow speed fuel circuit (venturi effect). The cap is placed to prevent the screw to be adjusted too rich (emissions, CARB etc.) or too lean (bad#7 might be a screw covering the pilot jet like on my Honda carburetor. If you look back at the picture, the limiter cap is partially blocking the view of a Phillips screw which is a cover for a 0.35mm hole. I call it a pilot jet but I really don't know what it is. It's definitely a hole with a special purpose that's not removable and uses a Phillips screw as a man-hole cover.

Last edited:

- Joined

- Feb 6, 2025

- Messages

- 54

Ah Ha! I suspected it being an adjustable air bleed all along!Without knowing the manufacturer of this carburetor, it could be both. As in the pilot orifice is fixed underneath the screw and the screw itself trims the pilot/idle mix.

The Keihins have a separate pilot (slow speed) jet/orifice (0.35 most GCV engines) and provides overall fuel for that circuit. The final trim is handled by the screw with the limiter cap on it, as it controls how much air is drawn across the idle/pilot/slow speed fuel circuit (venturi effect). The cap is placed to prevent the screw to be adjusted too rich (emissions, CARB etc.) or too lean (bad). You can ream the jet out to 0.40 and not touch the screw, or leave the jet alone and trim with the screw. I find in most cases the latter works fine for me.

The key to eliminating the surge might be that fixed pilot orifice under the Phillips screw.

Agreed.Ah Ha! I suspected it being an adjustable air bleed all along!

The key to eliminating the surge might be that fixed pilot orifice under the Phillips screw.

Although this may or may not be related, in many small engine carbs, the throttle butterfly uncovers small holes or slots in the idle circuit as the plate opens. When these clog, the exact problem you describe happens. These "Transition Ports" are notoriously difficult to clean. As the name suggests, they bridge the fuel need gap between a low idle and a more open throttle.

So the idle jet can be clear, the idle port can be clear, the main jet can be clear, but a speck of debris in the Transition Port can make operation in the low load, above idle zone very problematic.

Making matters worse, they often clog inside with a nearly invisible spec of dirt or aluminum. And they are so small on little engines, that anything there can cause issues. Sometimes an ultrasonic cleaner can dislodge something hidden inside.

So the idle jet can be clear, the idle port can be clear, the main jet can be clear, but a speck of debris in the Transition Port can make operation in the low load, above idle zone very problematic.

Making matters worse, they often clog inside with a nearly invisible spec of dirt or aluminum. And they are so small on little engines, that anything there can cause issues. Sometimes an ultrasonic cleaner can dislodge something hidden inside.

Exactly! I've found Berryman's B12 Chemtool sprayed in from carb throat (as seen in your pic) and where the pilot screw was removed, takes care of about 99.9% of anything built up/caught in the holes. It is aggressive enough to do proper cleaning, more so than most of the other carb cleaners IMHO. Gotta love these tiny fuel circuits.Although this may or may not be related, in many small engine carbs, the throttle butterfly uncovers small holes or slots in the idle circuit as the plate opens. When these clog, the exact problem you describe happens. These "Transition Ports" are notoriously difficult to clean. As the name suggests, they bridge the fuel need gap between a low idle and a more open throttle.

So the idle jet can be clear, the idle port can be clear, the main jet can be clear, but a speck of debris in the Transition Port can make operation in the low load, above idle zone very problematic.

Making matters worse, they often clog inside with a nearly invisible spec of dirt or aluminum. And they are so small on little engines, that anything there can cause issues. Sometimes an ultrasonic cleaner can dislodge something hidden inside.

Okay. Today I did a couple of cursory steps. I really believe the issue is the carburetor, but I have not gotten to that yet.

That said, I went to Advanced Auto and bought a couple new NGK BPR6HS spark plugs (same part number as the original). I was asked by someone on BITOG if I can take a look at the spark plug, so I am doing that here.

HI am also providing you a big longer video. You can hear it running. I repeated what I did in the prior video only I steadied the camera (iPhone) on a cheap Tri-Pod I ordered online to try to improve the video quality for all of you.

What is strange is that today it seems about the same as yesterday only it almost seemed to clean-up a bit after running at idle for a while the first time. Then I loaded it again, and it certainly did not clean up. It is still misfiring. No appreciable difference with a new plug.

Here is today's video. It is a bit longer run on a new Spark Plug.

I confirmed the new plug has a proper gap of > 0.025 but barely.

I also added a bit of choke, so you can see how it does with that. I also ran it at full speed (no economy).

3.8 Hours on it (original that came with the generator) next to the new:

That said, I went to Advanced Auto and bought a couple new NGK BPR6HS spark plugs (same part number as the original). I was asked by someone on BITOG if I can take a look at the spark plug, so I am doing that here.

HI am also providing you a big longer video. You can hear it running. I repeated what I did in the prior video only I steadied the camera (iPhone) on a cheap Tri-Pod I ordered online to try to improve the video quality for all of you.

What is strange is that today it seems about the same as yesterday only it almost seemed to clean-up a bit after running at idle for a while the first time. Then I loaded it again, and it certainly did not clean up. It is still misfiring. No appreciable difference with a new plug.

Here is today's video. It is a bit longer run on a new Spark Plug.

I confirmed the new plug has a proper gap of > 0.025 but barely.

I also added a bit of choke, so you can see how it does with that. I also ran it at full speed (no economy).

3.8 Hours on it (original that came with the generator) next to the new:

just per chance, does it have a air filter, if so remove it temporally and see if this changes this, and is there a fine filter screen from the fuel line inlet to carb. housing, you may want to check for this as a small amount of stuff can slow fuel flow, and make sure gas cap is on correctly.

Are you running it in ECO mode, if so does it do the same thing in Normal mode.

Plug a couple space heaters i to it and make another video. Sound like it's hunting for a load. My Briggs does the same thing.

My Honda EU2000i does the same thing when in ECO mode. It is constantly adjusting the throttle automatically searching for an electrical load. Normal behavior for a smaller inverter generator.

I listened to your video. It does seem to me that the RPM varies a bit too. Possibly the electronic control of the carb keeps that in check, but it does seem to 'lean surge' a bit.It is not hunting but misfiring. I would think if the low-speed was cogged it would be hunting. Also if the fuel line was clogged, it would not run fine at full RPM.

My money is on insufficient fueling at that particular RPM and light load. It should be rock steady.

Granted that original plug barely has 4 hours on it, but the insulator nose is awfully bright white. Points to a lean condition in my book.

I am with you all. I am going to do a quick filming tonight when it gets dark with the spark tester on to see if I see any cut-out of ignition. At any rate, I very strongly suspect I will be doing a carb cleaning.

I purchased B12 Chemtool for that. I will of course get a bunch of pictures for the group and maybe even some video, but I am not good at videoing things. Either way perhaps a cursory clean will fix it otherwise we may be able to find an adjustment to fix a lean condition.

I purchased B12 Chemtool for that. I will of course get a bunch of pictures for the group and maybe even some video, but I am not good at videoing things. Either way perhaps a cursory clean will fix it otherwise we may be able to find an adjustment to fix a lean condition.

A cursory clean won't help. I promise. Not once in the history of troublesome carbs has that worked for me.perhaps a cursory clean will fix it otherwise we may be able to find an adjustment to fix a lean condition.

I promise that if it is a clogged port, you must actively clean it. And that probably means spending a good bit of time understanding where the fuel goes and what it should look like when exiting the port. Sand or hard metal bits won't dissolve with carb cleaner. In many cases, a piece of copper wire or other probe is needed to dislodge stuck debris. Followed by flushing it backwards.

The spark tester arrived today, and I did NOT see any change in the spark from warm to cold. Sure is strange how when the engine warms up it runs with a misfire but not when it is cold.

I am going to pull the carburetor tomorrow and take pictures. The reason I am not pulling it today is that it looks like a project the way Yamaha built this there is not going to be room to remove the carburetor.

Here is the spark test. Maybe someone can take a look and listen and see if you see anything different than I do. I do NOT see any obvious interruption of spark.

I ordered two different carburetor cleaning sets of wires:

https://www.amazon.com/dp/B0894MTSJZ?ref=ppx_yo2ov_dt_b_fed_asin_title

https://www.amazon.com/dp/B07TZN6CXJ?ref=ppx_yo2ov_dt_b_fed_asin_title

I also have B12 Carb Cleaner from Berryman

I am hopeful this trick will work (NOT my video), but it looks like the EF2000is (predecessor to my EF2200IS) one can remove the studs:

I am hopeful the same trick works, so I will be trying to remove both nuts and tighten one against the other... then I will try to back out the stud with the inner nut.

I suspect it is the same. Both the current AND the prior version both have an MZ80 engine AND both look nearly identical.

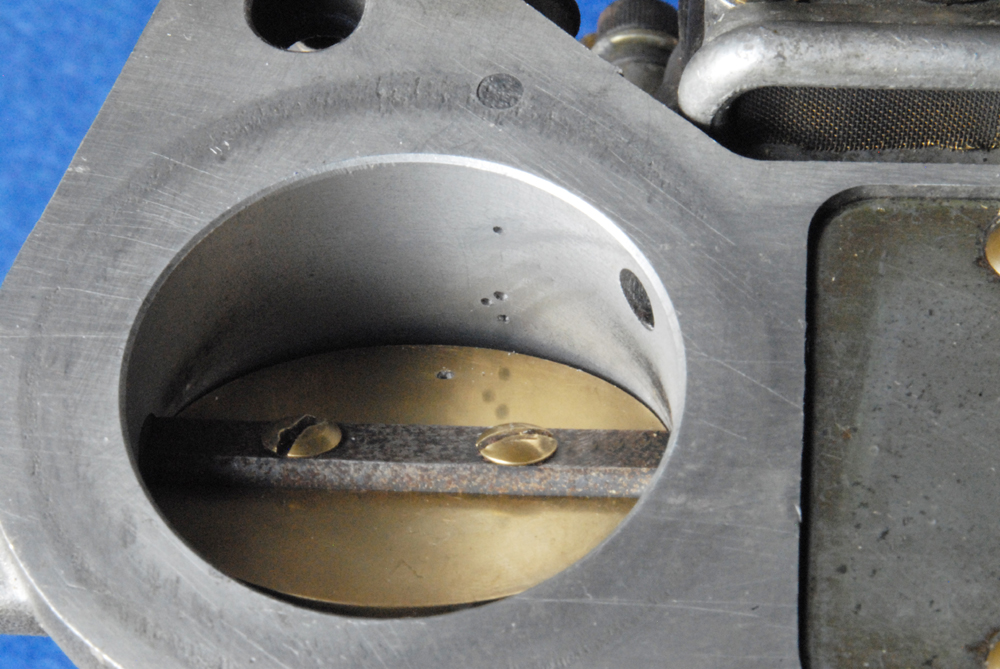

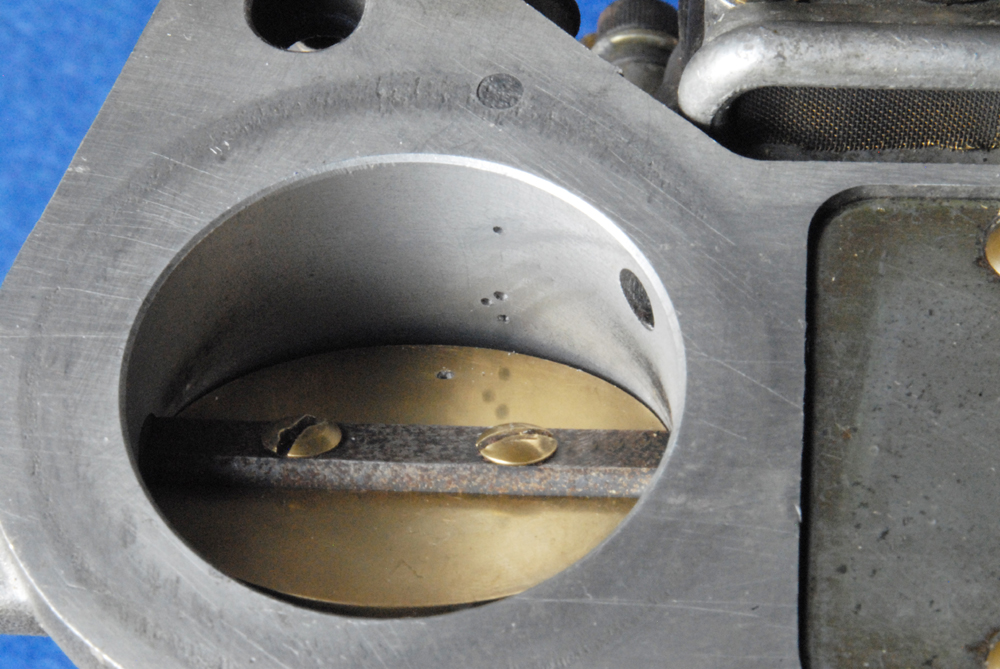

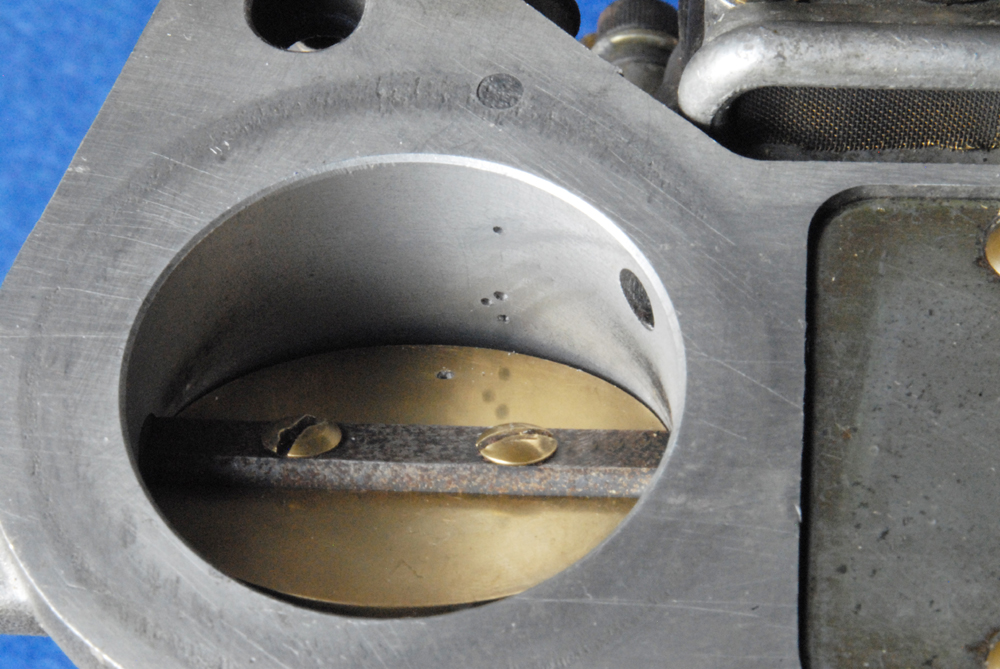

Here is a picture of my carb:

I am going to pull the carburetor tomorrow and take pictures. The reason I am not pulling it today is that it looks like a project the way Yamaha built this there is not going to be room to remove the carburetor.

Here is the spark test. Maybe someone can take a look and listen and see if you see anything different than I do. I do NOT see any obvious interruption of spark.

I ordered two different carburetor cleaning sets of wires:

https://www.amazon.com/dp/B0894MTSJZ?ref=ppx_yo2ov_dt_b_fed_asin_title

https://www.amazon.com/dp/B07TZN6CXJ?ref=ppx_yo2ov_dt_b_fed_asin_title

I also have B12 Carb Cleaner from Berryman

I am hopeful this trick will work (NOT my video), but it looks like the EF2000is (predecessor to my EF2200IS) one can remove the studs:

I am hopeful the same trick works, so I will be trying to remove both nuts and tighten one against the other... then I will try to back out the stud with the inner nut.

I suspect it is the same. Both the current AND the prior version both have an MZ80 engine AND both look nearly identical.

Here is a picture of my carb:

Don't go taking anything apart until you watch the video below and read all of the comments. Seems like this is a common problem that is solved by simply turning in the idle adjustment screw.

- Joined

- Feb 6, 2025

- Messages

- 54

I watched the extended length video. That little Yamaha generator and my Honda mower are doing the exact same thing. Both run perfectly fine while under load and then go into a lean misfire off load during idle. The generator's load is a toaster, the mower's load is the blade clutch being engaged to spin the blade. When they're under load, they're running off the main jet. When they're at idle, they're running off the idle jet or pilot jet as some people call it. So we're talking about two separate fuel circuits. I don't know why, but the EPA seems to think that it's the idle circuit that causes the most amount of pollution. What I'll probably end up doing is enlarging the idle jet from the stock 0.35mm to 0.40mm.

- Joined

- Feb 6, 2025

- Messages

- 54

Don't go taking anything apart until you watch the video below and read all of the comments. Seems like this is a common problem that is solved by simply turning in the idle adjustment screw.

What he did is increase the idle speed enough to where it no longer runs off the idle circuit. It now runs off the main jet.

Similar threads

- Replies

- 31

- Views

- 4K

- Replies

- 11

- Views

- 5K

- Locked

- Replies

- 4

- Views

- 9K

- Replies

- 81

- Views

- 14K