Detailed Topics

Timing Chain Problems II

Submit

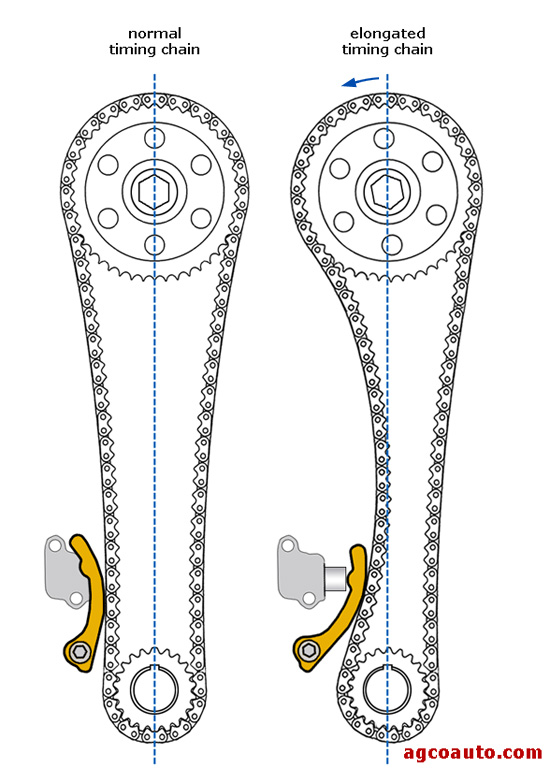

As a timing chain wears and gets longer, the camshaft starts to lag behind the crankshaft. We call this problem retarding the camshaft timing. An engine with retarded camshaft timing has lower performance and poor fuel economy.

When a timing chain elongates, cam timing is retarded

On engines with tensioners, the device extends and takes up slack on the idle side of the chain. This helps to keep the chain tight, but does not restore camshaft timing. Only replacing the worn chain and sprocket will restore proper mechanical timing.

Timing chain tensioners

The oil pressure of the engine hydraulically operates most timing chain tensioners. When the engine starts, oil pressure allows the tensioner to push the guide against the chain and remove slack. Turning off the engine causes the oil pressure to return to zero. With no oil pressure, gravity pushes the oil in the upper part of the engine, back to the oil pan. This leaves the passages, where the oil flows, empty and increases the time it takes to return oil to the tensioner on startup.

Quality OEM filter with the proper drain back valve

An anti drain-back valve, in a quality oil filter, helps keep oil in the passages, leading to the hydraulic tensioner. It does this by blocking the return of oil through the filter, to the oil pan. Without oil in the passages, it takes longer for the oil pump to pressurize the tensioner. Lack of tension prevents slack in the timing chain from being taken up. Allowing a timing chain to jerks on startup, increases wear and may break the chain guides. Once a chain guide breaks, camshaft timing may be erratic and engine performance will suffer. This is one way substandard oil filters promote timing chain problems.

Oil and timing chain wear

Another source of timing chain problems is oil of the wrong viscosity. A lower viscosity oil will flow faster than a heavier oil, especially when cold. Engine designers specify lower viscosity oil to promote quicker flow. Many engines with timing chains now specify 0W20 oil viscosity. Quickly pressurizing the hydraulic tensioner keeps the chain tight and reduces guide breakage.

Timing chains also have very specific lubrication requirements. Modern engines with timing chains, may have oil specifications which only synthetic oil will meet. This is not an option or a suggestion. Oil that does not meet the requirements will cause timing chain wear and very expensive problems. This is even more critical on direct-injection engines, which may use the timing chain to drive the injector pump. Extra load on the chain, combined with insufficient oil, is a recipe for disaster.

Symptoms of a worn timing chain

One of the more common symptoms of a worn timing chain is noise, especially on startup. A rattling noise coming from the engine may show a seriously worn timing chain. Slack in the chain allows it to strike the timing cover. This may produce debris, worn from the timing cover or produce a hole in the cover and a serious oil leak.

Ford modular V-8 engines, such as the 4.6, 5.0 and 5.4 liter seem to have a particular problem with this. After a few seconds, the tensioners tighten the chains and the noise stops. Lack of the noise after running, does not suggest the lack of a problem. The tensioners are masking the noise.

Ford timing cover worn from slack in timing chain

Worn chains may rub on the timing cover and internal engine damage may result. A timing chain, which slips on its sprockets, will stop the engine and may cause extensive damage.

The General Motors 3.6 liter engine also appears to have timing chain problems. Extended oil changes combined with a weak design, may cause this engine to jump timing at low mileage.

Engine removal to replace timing chains on GM 3.6L

The most common symptoms are a check engine light and low engine performance. An update to the engine computer changes the oil-reminder interval and reduces engine performance. Correction requires engine removal and timing chain and sprocket replacement.

Timing chain wear often gets misdiagnosed and may cause a rough idle, a lack of performance, reduced fuel mileage and several check engine light codes. Finding the problem is difficult, as the timing chain is deep in the engine. In the past, we used the ignition distributor to show timing chain problems. Almost no engines have a distributor today and many no longer have timing marks.

Verifying camshaft timing is often a matter of engine disassembly. We need several special tools on most engines to check valve timing. Some engines no longer have a key in the crankshaft and even positioning the sprocket requires a specialty tool set.

Timing chain replacement on modern overhead cam engines is very complex. Many engines would benefit from restoring the camshaft timing to specifications, but repair is very involved and expensive. As with most things, prevention is a far more cost-effective plan.

Preventing timing chain problems

Use only the proper viscosity and specification oil

Use only the OEM oil filter

Change oil based on use and not just mileage

Have any noises in the engine checked and repaired. Sorry about the length of the post, just a cut and paste of an article. I'm not sure of the total accuracy, but got me thinking a little.

Timing Chain Problems II

Submit

As a timing chain wears and gets longer, the camshaft starts to lag behind the crankshaft. We call this problem retarding the camshaft timing. An engine with retarded camshaft timing has lower performance and poor fuel economy.

When a timing chain elongates, cam timing is retarded

On engines with tensioners, the device extends and takes up slack on the idle side of the chain. This helps to keep the chain tight, but does not restore camshaft timing. Only replacing the worn chain and sprocket will restore proper mechanical timing.

Timing chain tensioners

The oil pressure of the engine hydraulically operates most timing chain tensioners. When the engine starts, oil pressure allows the tensioner to push the guide against the chain and remove slack. Turning off the engine causes the oil pressure to return to zero. With no oil pressure, gravity pushes the oil in the upper part of the engine, back to the oil pan. This leaves the passages, where the oil flows, empty and increases the time it takes to return oil to the tensioner on startup.

Quality OEM filter with the proper drain back valve

An anti drain-back valve, in a quality oil filter, helps keep oil in the passages, leading to the hydraulic tensioner. It does this by blocking the return of oil through the filter, to the oil pan. Without oil in the passages, it takes longer for the oil pump to pressurize the tensioner. Lack of tension prevents slack in the timing chain from being taken up. Allowing a timing chain to jerks on startup, increases wear and may break the chain guides. Once a chain guide breaks, camshaft timing may be erratic and engine performance will suffer. This is one way substandard oil filters promote timing chain problems.

Oil and timing chain wear

Another source of timing chain problems is oil of the wrong viscosity. A lower viscosity oil will flow faster than a heavier oil, especially when cold. Engine designers specify lower viscosity oil to promote quicker flow. Many engines with timing chains now specify 0W20 oil viscosity. Quickly pressurizing the hydraulic tensioner keeps the chain tight and reduces guide breakage.

Timing chains also have very specific lubrication requirements. Modern engines with timing chains, may have oil specifications which only synthetic oil will meet. This is not an option or a suggestion. Oil that does not meet the requirements will cause timing chain wear and very expensive problems. This is even more critical on direct-injection engines, which may use the timing chain to drive the injector pump. Extra load on the chain, combined with insufficient oil, is a recipe for disaster.

Symptoms of a worn timing chain

One of the more common symptoms of a worn timing chain is noise, especially on startup. A rattling noise coming from the engine may show a seriously worn timing chain. Slack in the chain allows it to strike the timing cover. This may produce debris, worn from the timing cover or produce a hole in the cover and a serious oil leak.

Ford modular V-8 engines, such as the 4.6, 5.0 and 5.4 liter seem to have a particular problem with this. After a few seconds, the tensioners tighten the chains and the noise stops. Lack of the noise after running, does not suggest the lack of a problem. The tensioners are masking the noise.

Ford timing cover worn from slack in timing chain

Worn chains may rub on the timing cover and internal engine damage may result. A timing chain, which slips on its sprockets, will stop the engine and may cause extensive damage.

The General Motors 3.6 liter engine also appears to have timing chain problems. Extended oil changes combined with a weak design, may cause this engine to jump timing at low mileage.

Engine removal to replace timing chains on GM 3.6L

The most common symptoms are a check engine light and low engine performance. An update to the engine computer changes the oil-reminder interval and reduces engine performance. Correction requires engine removal and timing chain and sprocket replacement.

Timing chain wear often gets misdiagnosed and may cause a rough idle, a lack of performance, reduced fuel mileage and several check engine light codes. Finding the problem is difficult, as the timing chain is deep in the engine. In the past, we used the ignition distributor to show timing chain problems. Almost no engines have a distributor today and many no longer have timing marks.

Verifying camshaft timing is often a matter of engine disassembly. We need several special tools on most engines to check valve timing. Some engines no longer have a key in the crankshaft and even positioning the sprocket requires a specialty tool set.

Timing chain replacement on modern overhead cam engines is very complex. Many engines would benefit from restoring the camshaft timing to specifications, but repair is very involved and expensive. As with most things, prevention is a far more cost-effective plan.

Preventing timing chain problems

Use only the proper viscosity and specification oil

Use only the OEM oil filter

Change oil based on use and not just mileage

Have any noises in the engine checked and repaired. Sorry about the length of the post, just a cut and paste of an article. I'm not sure of the total accuracy, but got me thinking a little.