- Joined

- Nov 19, 2023

- Messages

- 980

Federal gov will announce the awarded subsidized chip mfg.

Are we finally getting more on shore arm based, x86 chip designed and made in the usa?

How long will plans announced today take to materialize?

www.cnbc.com

www.cnbc.com

Are we finally getting more on shore arm based, x86 chip designed and made in the usa?

How long will plans announced today take to materialize?

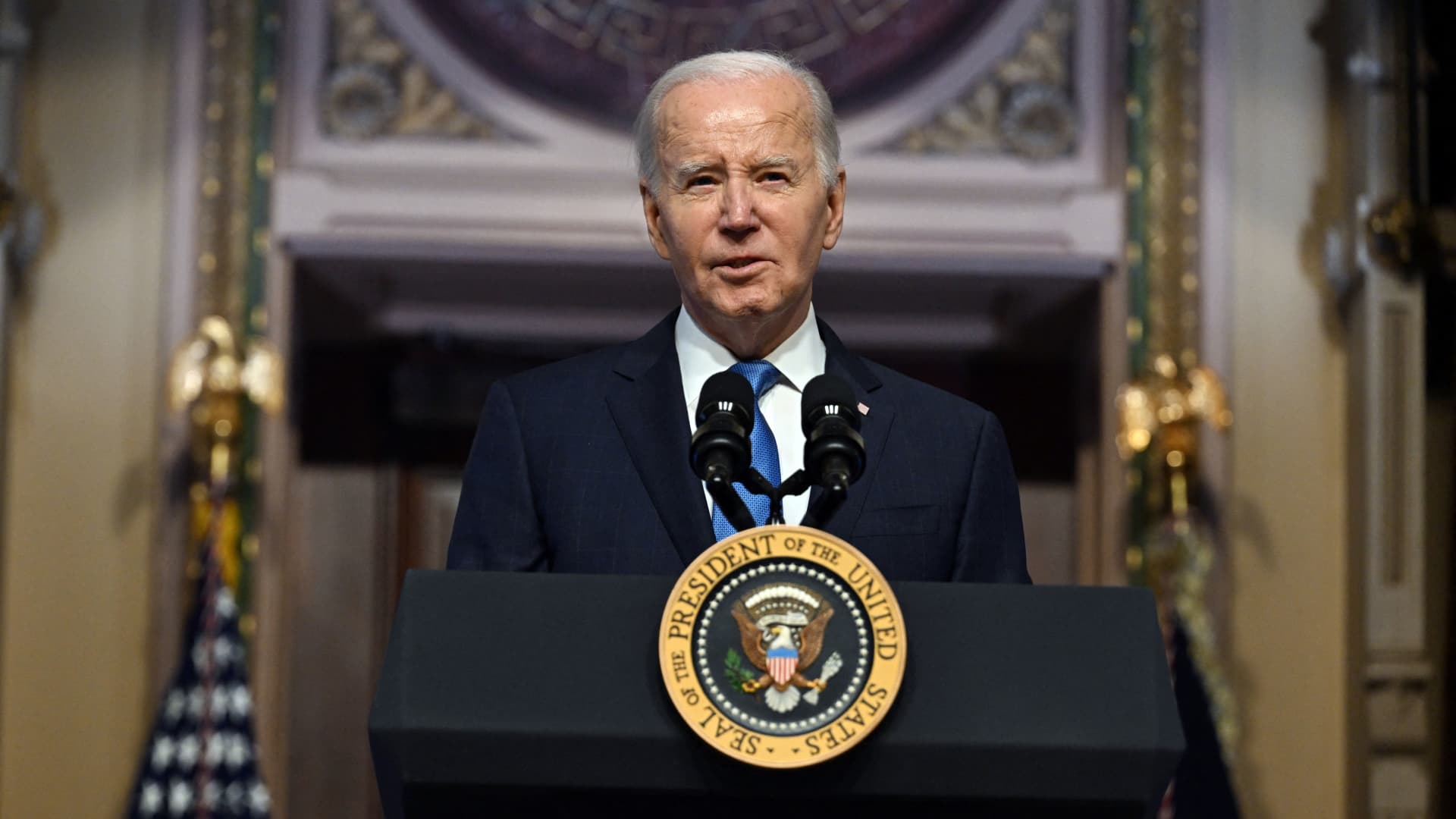

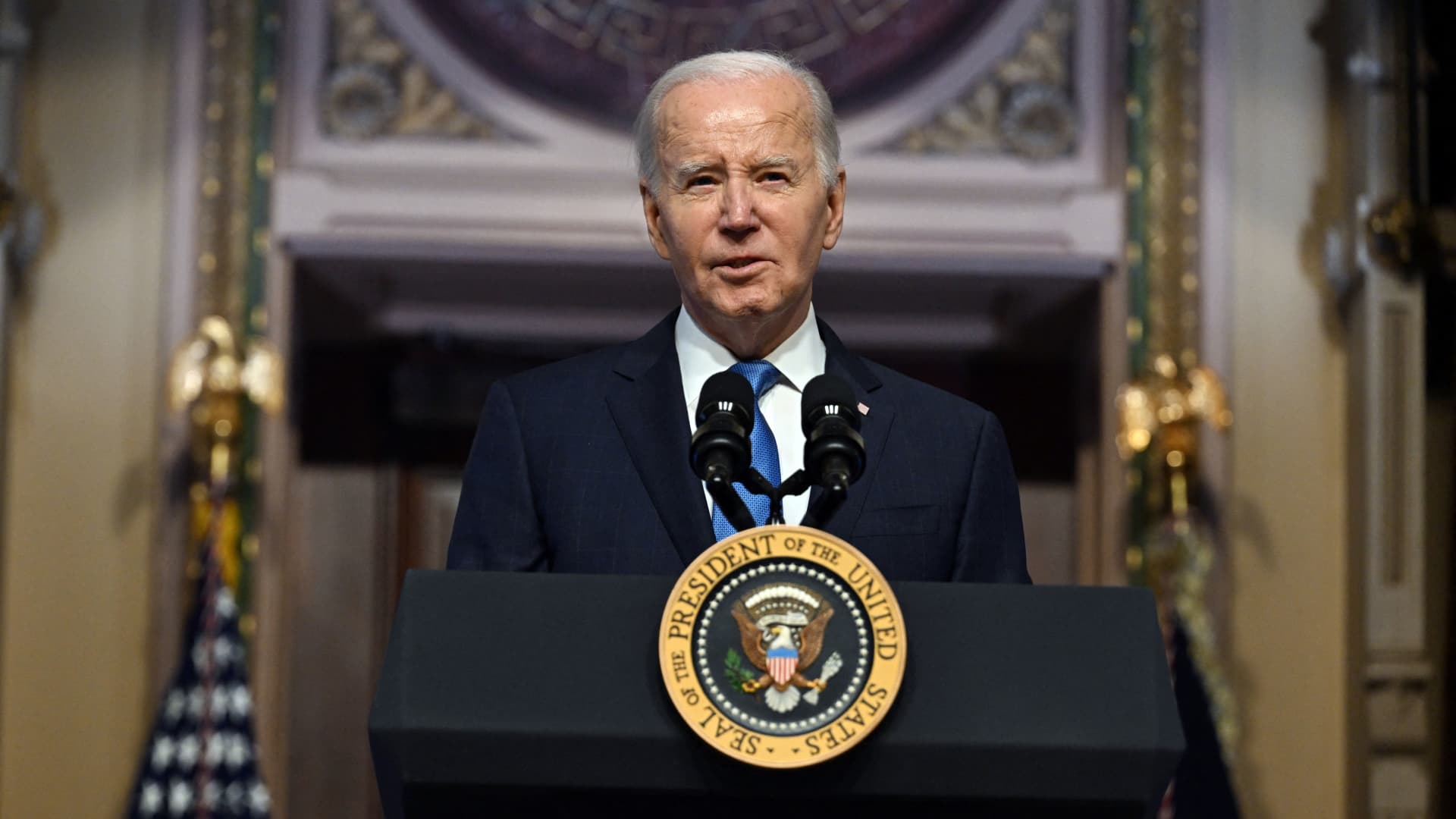

U.S. to reportedly announce billions of dollars in subsidies for advanced chips

The Biden administration is expected to award billions of dollars in subsidies to top semiconductor companies in the coming weeks to help build new factories.