I'm not super familiar with hydraulic Fluid and the types or differences.

My 75ish owatonna skid steer has ATF in the hydraulic system " per the previous owner " he claims that's what it takes.

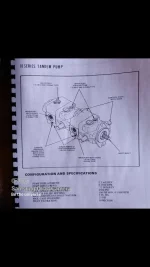

I want to replace the filters in the near future and do a fluid change. I don't have a manual yet so this is why I'm asking here.

If I need to use ATF, is there an advantage in using hydraulic fluids? I can get aw32 aw46 and universal tractor fluid all for pretty cheap at my work, I'd have to go to tractor supply for ATF as I don't get much break on it. I want whatever is hypothetically best for the machine, I just don't know what advantages there is. I also don't know if there's better technology's from then or if there's a specific reason why they say ATF.

My skid steer uses 2 hydraulic pumps to turn chains that turn the wheels. I have one main pump that hooks to the smaller ones. The chains go through an oil bath at the bottom " assumingly "

Thank you everyone. I hope to get my manuals soon

My 75ish owatonna skid steer has ATF in the hydraulic system " per the previous owner " he claims that's what it takes.

I want to replace the filters in the near future and do a fluid change. I don't have a manual yet so this is why I'm asking here.

If I need to use ATF, is there an advantage in using hydraulic fluids? I can get aw32 aw46 and universal tractor fluid all for pretty cheap at my work, I'd have to go to tractor supply for ATF as I don't get much break on it. I want whatever is hypothetically best for the machine, I just don't know what advantages there is. I also don't know if there's better technology's from then or if there's a specific reason why they say ATF.

My skid steer uses 2 hydraulic pumps to turn chains that turn the wheels. I have one main pump that hooks to the smaller ones. The chains go through an oil bath at the bottom " assumingly "

Thank you everyone. I hope to get my manuals soon