2008 Ford F-250 6.4L

10,028 miles on oil, 20110 on engine, 1qt. Makeup Oil

Factory oil/filter changed at 5k w/ Mobil 15w40 and this oil was put in at 10,028 miles.

There is no DPF filter on this truck, so there are no regens. The truck does run a tune to disable the regens, but it is not raced, hot-rodded, etc. There was about 1,000 miles or 10% towing a 12k 5th wheel.

Comments on the Aluminum, Iron, Potassium, and Silicon? Blackstone told me the potassium could be from the solider flux in the EGR cooler and that it should go down. The sodium levels are low, so they don't suspect coolant. From my calculations, the aluminum is lower than the universal averages, but the Iron is higher. I will check the air intake and filter, for a leaking connection. The air filter is original, but according to Ford doesn't need replacement until the "filter minder" says???

I put more Rotella 5w40 Synthetic in and plan to run another 10k and sample. I won't go past the 10k oil changes as this is a requirement of Ford's warranty.

Blackstone Comments:

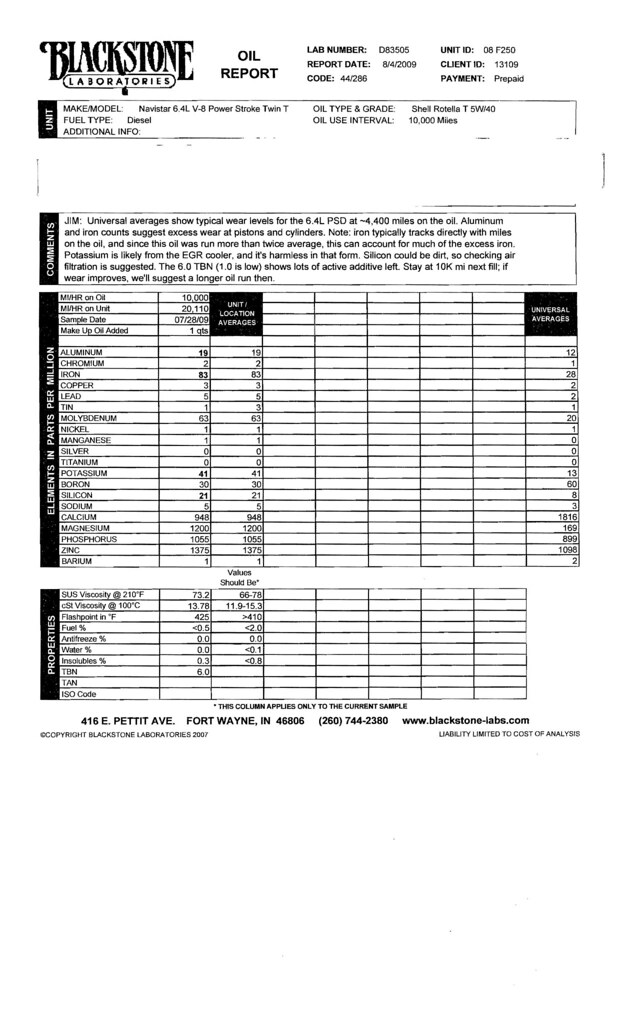

Universal averages show typical wear levels for the 6.4L PSD at ~4,400 miles on the oil. Aluminum

and iron counts suggest excess wear at pistons and cylinders. Note: iron typically tracks directly with miles

on the oil, and since this oil was run more than twice average, this can account for much of the excess iron.

Potassium is likely from the EGR cooler, and it's harmless in that form. Silicon could be dirt, so checking air

filtration is suggested. The 6.0 TBN (1.0 is low) shows lots of active additive left. Stay at 10K mi next fill; if

wear improves, we'll suggest a longer oil run then.

UOA/Univ. Averages

Aluminum: 19/12

Chromium: 2/1

Iron: 83/28

Copper: 3/2

Lead: 5/2

Tin: 1/1

Moly: 63/20

Nickel: 1/1

Manganese: 1/0

Silver: 0/0

Titanium: 0/0

Potassium: 41/13

Boron: 30/60

Silicon: 21/8

Sodium: 5/3

Calcium: 948/1816

Magnesium: 1200/169

Phosphorus: 1055/899

Zinc: 1375/1098

Barium: 1/2

SUS Viscosity @ 210: 73.2 - 66-78 (Values Should Be)

cSt Viscosity @ 100: 13.78 - 11.9 - 15.3

Flashpoint: 425/>410

Fuel%: Antifreeze: 0/0

Water: 0/ Insolubles: .3/ TBN 6.0

10,028 miles on oil, 20110 on engine, 1qt. Makeup Oil

Factory oil/filter changed at 5k w/ Mobil 15w40 and this oil was put in at 10,028 miles.

There is no DPF filter on this truck, so there are no regens. The truck does run a tune to disable the regens, but it is not raced, hot-rodded, etc. There was about 1,000 miles or 10% towing a 12k 5th wheel.

Comments on the Aluminum, Iron, Potassium, and Silicon? Blackstone told me the potassium could be from the solider flux in the EGR cooler and that it should go down. The sodium levels are low, so they don't suspect coolant. From my calculations, the aluminum is lower than the universal averages, but the Iron is higher. I will check the air intake and filter, for a leaking connection. The air filter is original, but according to Ford doesn't need replacement until the "filter minder" says???

I put more Rotella 5w40 Synthetic in and plan to run another 10k and sample. I won't go past the 10k oil changes as this is a requirement of Ford's warranty.

Blackstone Comments:

Universal averages show typical wear levels for the 6.4L PSD at ~4,400 miles on the oil. Aluminum

and iron counts suggest excess wear at pistons and cylinders. Note: iron typically tracks directly with miles

on the oil, and since this oil was run more than twice average, this can account for much of the excess iron.

Potassium is likely from the EGR cooler, and it's harmless in that form. Silicon could be dirt, so checking air

filtration is suggested. The 6.0 TBN (1.0 is low) shows lots of active additive left. Stay at 10K mi next fill; if

wear improves, we'll suggest a longer oil run then.

UOA/Univ. Averages

Aluminum: 19/12

Chromium: 2/1

Iron: 83/28

Copper: 3/2

Lead: 5/2

Tin: 1/1

Moly: 63/20

Nickel: 1/1

Manganese: 1/0

Silver: 0/0

Titanium: 0/0

Potassium: 41/13

Boron: 30/60

Silicon: 21/8

Sodium: 5/3

Calcium: 948/1816

Magnesium: 1200/169

Phosphorus: 1055/899

Zinc: 1375/1098

Barium: 1/2

SUS Viscosity @ 210: 73.2 - 66-78 (Values Should Be)

cSt Viscosity @ 100: 13.78 - 11.9 - 15.3

Flashpoint: 425/>410

Fuel%: Antifreeze: 0/0

Water: 0/ Insolubles: .3/ TBN 6.0

Last edited: