You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

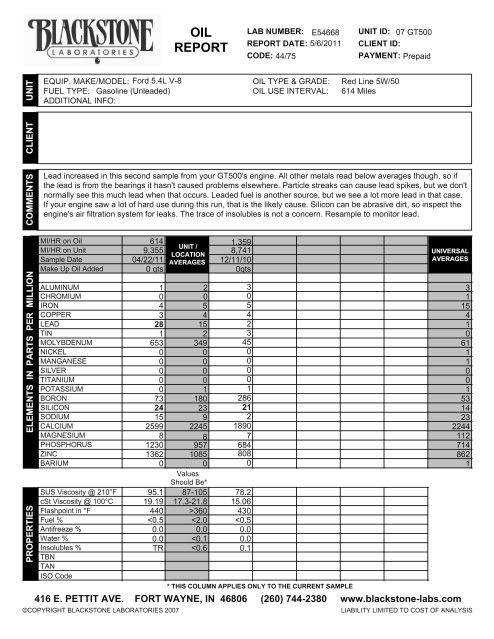

Red Line 5W50, 614 Miles, 2007 Ford GT500

- Thread starter SIXSPEED

- Start date

- Status

- Not open for further replies.

I bet the lead number would decrease if you ran the same oil again.

Either way, I wouldn't worry about it at all. AFAIK, Red Line oils tend to use aggressive chemistries that will make ICP-generated wear numbers go nuts. It doesn't mean there's any additional wear. In fact, it could be correlated with decreased wear.

Either way, I wouldn't worry about it at all. AFAIK, Red Line oils tend to use aggressive chemistries that will make ICP-generated wear numbers go nuts. It doesn't mean there's any additional wear. In fact, it could be correlated with decreased wear.

OVERKILL

$100 Site Donor 2021

Originally Posted By: pzev

I've heard the phrase particle streak used in instances like this. A small piece of grit gets taken for a ride through one of the bearings shedding some wear materials as it passes.

Anyways, looks fine otherwise.

Except the Modular engines don't have lead in their bearings.

Quote:

Clevite BiMetal engine bearings feature a 100% lead free aluminum silicon bi-metal material; this includes 60% more silicon than leading competitor's bi-metal material for better conditioning of journal surfaces. These BiMetal bearings also offer greater wear resistance than leading competitor's bi-metal material, as well as greater seizure resistance than the leading competitor. Clevite BiMetal bearings feature 100% bored ID's for precision and surface characteristics and where appropriate - straight shell main bearings utilizing an "umbrella" groove that allows for superior oil control and improved pressure.

I've heard the phrase particle streak used in instances like this. A small piece of grit gets taken for a ride through one of the bearings shedding some wear materials as it passes.

Anyways, looks fine otherwise.

Except the Modular engines don't have lead in their bearings.

Quote:

Clevite BiMetal engine bearings feature a 100% lead free aluminum silicon bi-metal material; this includes 60% more silicon than leading competitor's bi-metal material for better conditioning of journal surfaces. These BiMetal bearings also offer greater wear resistance than leading competitor's bi-metal material, as well as greater seizure resistance than the leading competitor. Clevite BiMetal bearings feature 100% bored ID's for precision and surface characteristics and where appropriate - straight shell main bearings utilizing an "umbrella" groove that allows for superior oil control and improved pressure.

Originally Posted By: d00df00d

I bet the lead number would decrease if you ran the same oil again.

Either way, I wouldn't worry about it at all. AFAIK, Red Line oils tend to use aggressive chemistries that will make ICP-generated wear numbers go nuts. It doesn't mean there's any additional wear. In fact, it could be correlated with decreased wear.

Sorry I have trouble understanding the correlation. Aggressive chemistry should not increase contaminant/wear metals. If it increased contaminant levels, then that simply means it is more abrasive.

Increased contaminant levels doesn't correlate with decreased wear. If those increased levels are due to the chemistry of the oil, I would be careful in using it. You are better off finding an oil that will protect your engine better by minimizing wear metals and contaminants.

An oil shouldn't cause wear metals to increase. Unless something was wrong with the analysis, I wouldn't necessarily relate it to aggressive chemistry.

I bet the lead number would decrease if you ran the same oil again.

Either way, I wouldn't worry about it at all. AFAIK, Red Line oils tend to use aggressive chemistries that will make ICP-generated wear numbers go nuts. It doesn't mean there's any additional wear. In fact, it could be correlated with decreased wear.

Sorry I have trouble understanding the correlation. Aggressive chemistry should not increase contaminant/wear metals. If it increased contaminant levels, then that simply means it is more abrasive.

Increased contaminant levels doesn't correlate with decreased wear. If those increased levels are due to the chemistry of the oil, I would be careful in using it. You are better off finding an oil that will protect your engine better by minimizing wear metals and contaminants.

An oil shouldn't cause wear metals to increase. Unless something was wrong with the analysis, I wouldn't necessarily relate it to aggressive chemistry.

Originally Posted By: pzev

Gotcha, thanks for the info.

So I wonder what the lead is from?

I am 99% sure that the lead is from your main bearings that support the crankshaft. Reason being is that, I believe the engine is a high performance derivative of the base engine. Regardless, it should be using lead-copper bearings. We use lead-copper bearings in some of the engines we build; others have aluminum bearings.

Gotcha, thanks for the info.

So I wonder what the lead is from?

I am 99% sure that the lead is from your main bearings that support the crankshaft. Reason being is that, I believe the engine is a high performance derivative of the base engine. Regardless, it should be using lead-copper bearings. We use lead-copper bearings in some of the engines we build; others have aluminum bearings.

Well, I don't know enough about this engine to comment on the bearings, but if they are indeed lead....then I'm still leaning towards particle streak. Honestly, I can't see why there would be lead in the UOA if it didn't have a lead bearing somewhere.

Not unless they are using lead as an additive now .

.

As for the aggressive chemistry remarks, what he was talking about is the theory that redline has a tendency to clean up anything left behind, including previous wear metals. These can cause an increase in wear numbers for the first couple redline OCI's. Additionally, ICP generated UOA wear numbers don't take into account any large debris in the oil. So you could have an engine that has seen catastrophic wear , but in a UOA it wouldn't look all that bad. Which is why many people take the wear number readings off common UOA's with a grain of salt.

Not unless they are using lead as an additive now

As for the aggressive chemistry remarks, what he was talking about is the theory that redline has a tendency to clean up anything left behind, including previous wear metals. These can cause an increase in wear numbers for the first couple redline OCI's. Additionally, ICP generated UOA wear numbers don't take into account any large debris in the oil. So you could have an engine that has seen catastrophic wear , but in a UOA it wouldn't look all that bad. Which is why many people take the wear number readings off common UOA's with a grain of salt.

Originally Posted By: dtt004

Sorry I have trouble understanding the correlation. Aggressive chemistry should not increase contaminant/wear metals. If it increased contaminant levels, then that simply means it is more abrasive.

Increased contaminant levels doesn't correlate with decreased wear. If those increased levels are due to the chemistry of the oil, I would be careful in using it. You are better off finding an oil that will protect your engine better by minimizing wear metals and contaminants.

An oil shouldn't cause wear metals to increase. Unless something was wrong with the analysis, I wouldn't necessarily relate it to aggressive chemistry.

There are a few statements to this effect floating around on the board:

https://bobistheoilguy.com/forums/posts/1858390/

https://bobistheoilguy.com/forums/posts/1858390/

There's another one from Dave at Red Line that I can't seem to find right now...

Sorry I have trouble understanding the correlation. Aggressive chemistry should not increase contaminant/wear metals. If it increased contaminant levels, then that simply means it is more abrasive.

Increased contaminant levels doesn't correlate with decreased wear. If those increased levels are due to the chemistry of the oil, I would be careful in using it. You are better off finding an oil that will protect your engine better by minimizing wear metals and contaminants.

An oil shouldn't cause wear metals to increase. Unless something was wrong with the analysis, I wouldn't necessarily relate it to aggressive chemistry.

There are a few statements to this effect floating around on the board:

https://bobistheoilguy.com/forums/posts/1858390/

https://bobistheoilguy.com/forums/posts/1858390/

There's another one from Dave at Red Line that I can't seem to find right now...

OVERKILL

$100 Site Donor 2021

Originally Posted By: dtt004

Originally Posted By: pzev

Gotcha, thanks for the info.

So I wonder what the lead is from?

I am 99% sure that the lead is from your main bearings that support the crankshaft. Reason being is that, I believe the engine is a high performance derivative of the base engine. Regardless, it should be using lead-copper bearings. We use lead-copper bearings in some of the engines we build; others have aluminum bearings.

It doesn't.

The Modular engines all use the Clevite bimetal bearings.

The (broken) bottom of a 5.4L from a Lightning for example:

Clevite bimetal bearings.

Originally Posted By: pzev

Gotcha, thanks for the info.

So I wonder what the lead is from?

I am 99% sure that the lead is from your main bearings that support the crankshaft. Reason being is that, I believe the engine is a high performance derivative of the base engine. Regardless, it should be using lead-copper bearings. We use lead-copper bearings in some of the engines we build; others have aluminum bearings.

It doesn't.

The Modular engines all use the Clevite bimetal bearings.

The (broken) bottom of a 5.4L from a Lightning for example:

Clevite bimetal bearings.

The motor is a high-performance supercharged 5.4L modular. I only use unleaded fuel, did not use any additives and did not beat on the car. I wonder where the lead would come from if not the bearings. I have Mobile 1 5W50 in the sump now ... will check again in a few 1000 miles.

Last edited:

OVERKILL

$100 Site Donor 2021

Originally Posted By: SIXSPEED

The motor is a high-performance supercharged 5.4L modular. I only use unleaded fuel, did not use any additives and did not beat on the car. I wonder where the lead would come from if not the bearings. I have Mobile 1 5W50 in the sump now ... will check again in a few 1000 miles.

Could even be from the oil.

Same reason we sometimes see copper in Modular UOA's, even there there isn't any in the engine.

The motor is a high-performance supercharged 5.4L modular. I only use unleaded fuel, did not use any additives and did not beat on the car. I wonder where the lead would come from if not the bearings. I have Mobile 1 5W50 in the sump now ... will check again in a few 1000 miles.

Could even be from the oil.

Same reason we sometimes see copper in Modular UOA's, even there there isn't any in the engine.

It could also be an error in the report.

There are plenty of UOA reports here that had to be done over because of errors.

There are plenty of UOA reports here that had to be done over because of errors.

If they still have the remainder of your sample, ask them to run the pb test again.

^I agree with asking for a re-sample, if they still have it.

So, are non of the internals iron in this engine?

So, are non of the internals iron in this engine?

Last edited:

OP_ I'd talk to Dave, you MAY be able to safely go 1 step down in viscosity to a 40 with the RL (true synthetic) and pick up some HP - as long as you are not aggressively tracking this car and killing the oil temps. I would also stick with ONE oil type if its satisfactory - not good to be flip flopping chemistrys as this can "loose the hounds of Hades", as one package supersedes the other and cause odd shedding/wear.

Last edited:

Brass bushings may contain lead.

Originally Posted By: ARCOgraphite

OP_ I'd talk to Dave, you MAY be able to safely go 1 step down in viscosity to a 40 with the RL (true synthetic) and pick up some HP - as long as you are not aggressively tracking this car and killing the oil temps. I would also stick with ONE oil type if its satisfactory - not good to be flip flopping chemistrys as this can "loose the hounds of Hades", as one package supersedes the other and cause odd shedding/wear.

With the exception of the "true synthetic" comment (I dislike the terminology), I heartily endorse all of the above.

OP_ I'd talk to Dave, you MAY be able to safely go 1 step down in viscosity to a 40 with the RL (true synthetic) and pick up some HP - as long as you are not aggressively tracking this car and killing the oil temps. I would also stick with ONE oil type if its satisfactory - not good to be flip flopping chemistrys as this can "loose the hounds of Hades", as one package supersedes the other and cause odd shedding/wear.

With the exception of the "true synthetic" comment (I dislike the terminology), I heartily endorse all of the above.

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 586

- Replies

- 8

- Views

- 252

- Replies

- 13

- Views

- 298

- Replies

- 11

- Views

- 2K