expatIn the U.K. the TS3 was known as an engine that consumed a lot of lubricating oil. Was that really the case? Do you know why? Was the TS4 ever in production? [/quote said:At the time I don't think it was considered a problem,most engines used oil,and leaked a lot too...oil change intervals were shorter,there was oil on tap at the pumps.These days it may be considered an oil burner.

I don't think the TS4 was ever fitted to a production truck,but it was a runner.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Opposed Piston Engines

- Thread starter Shar

- Start date

- Status

- Not open for further replies.

Hi,

as two strokes they used oil and as Silk said it mattered little (DD two stokes IME use/lose about a litre/1k) too

Rudolf Diesel played a real role working for Sulzer - the Swiss Co - in the late 1800s

It is also interesteing to recall some "headless" diesel engines - a certain Leyland comes to mind....................

as two strokes they used oil and as Silk said it mattered little (DD two stokes IME use/lose about a litre/1k) too

Rudolf Diesel played a real role working for Sulzer - the Swiss Co - in the late 1800s

It is also interesteing to recall some "headless" diesel engines - a certain Leyland comes to mind....................

Originally Posted By: Doug Hillary

It is also interesteing to recall some "headless" diesel engines - a certain Leyland comes to mind....................

Ergo cab Lynx?

It is also interesteing to recall some "headless" diesel engines - a certain Leyland comes to mind....................

Ergo cab Lynx?

Originally Posted By: Doug Hillary

Hi,

as two strokes they used oil and as Silk said it mattered little (DD two stokes IME use/lose about a litre/1k) too

Rudolf Diesel played a real role working for Sulzer - the Swiss Co - in the late 1800s

It is also interesteing to recall some "headless" diesel engines - a certain Leyland comes to mind....................

Why because they are two strokes? Because of the Supercharger?

Please, What 'Headless Leyland' are you referring to?

Hi,

as two strokes they used oil and as Silk said it mattered little (DD two stokes IME use/lose about a litre/1k) too

Rudolf Diesel played a real role working for Sulzer - the Swiss Co - in the late 1800s

It is also interesteing to recall some "headless" diesel engines - a certain Leyland comes to mind....................

Why because they are two strokes? Because of the Supercharger?

Please, What 'Headless Leyland' are you referring to?

Hi,

expat _ I refer to the Leyland 500 fixed head engine series (there were some variants). This engine was used in a number of Leyland applications - and even turbocharged in some

I knew the Development Engineers Tim Varley (400/500) and Rod Bamford (680/6.98 different series) )for this potentially great engine (400/500) and first met with them in the 1960s

By the early 1970s there was no money to refine and develop it so it died a slow and agonising death! As two bright Engineers they were devastated by the lack of Capital and foresight as Leyland was dying! I last met with these two excellent Engineers and the Manager of the Heavy Truck programme (C. Cearnes) in Preston in Novemebr/December 1975

With DD and the "Commer knocker" and their scavanging process a certain amount of lubricant was a "design loss" anyway

expat _ I refer to the Leyland 500 fixed head engine series (there were some variants). This engine was used in a number of Leyland applications - and even turbocharged in some

I knew the Development Engineers Tim Varley (400/500) and Rod Bamford (680/6.98 different series) )for this potentially great engine (400/500) and first met with them in the 1960s

By the early 1970s there was no money to refine and develop it so it died a slow and agonising death! As two bright Engineers they were devastated by the lack of Capital and foresight as Leyland was dying! I last met with these two excellent Engineers and the Manager of the Heavy Truck programme (C. Cearnes) in Preston in Novemebr/December 1975

With DD and the "Commer knocker" and their scavanging process a certain amount of lubricant was a "design loss" anyway

Hi,

expat - Correct - an integral head/block structure. The idea has merit but on-going servicing presents problems.

Today the problems could be solved - in the 1960s and without CAD/CAM and investment Capital they became insurmountable

expat - Correct - an integral head/block structure. The idea has merit but on-going servicing presents problems.

Today the problems could be solved - in the 1960s and without CAD/CAM and investment Capital they became insurmountable

Originally Posted By: Doug Hillary

Hi,

expat - Correct - an integral head/block structure. The idea has merit but on-going servicing presents problems.

Today the problems could be solved - in the 1960s and without CAD/CAM and investment Capital they became insurmountable

The Story of British Leyland!

Hi,

expat - Correct - an integral head/block structure. The idea has merit but on-going servicing presents problems.

Today the problems could be solved - in the 1960s and without CAD/CAM and investment Capital they became insurmountable

The Story of British Leyland!

Hi,

Shannow - I would like to know too!

Leyland had a number of engine families up to 15 litres

Mostly they were great and at Morris Commercial we preferred them over the Morris series

Various applications were devised, including horizontal and rear engined - again lack of Capital killed the beast

The Leyland National bus was a good design and a reasonable product in the end

Shannow - I would like to know too!

Leyland had a number of engine families up to 15 litres

Mostly they were great and at Morris Commercial we preferred them over the Morris series

Various applications were devised, including horizontal and rear engined - again lack of Capital killed the beast

The Leyland National bus was a good design and a reasonable product in the end

11.3 and 12.5L...not much more info.

I've seen one, and it was horizontal under the floor.

http://www.zigzagrailway.com.au/rail_motors.php

I've seen one, and it was horizontal under the floor.

http://www.zigzagrailway.com.au/rail_motors.php

I think the Leyland under floor bus engines were the 680 on it's side.I've only looked at one through the access hole,and quietly walked away - no way was I going to work on that!

Hi,

yes the 680 came in a variety of configurations and had quite a long production life!

Bamford the Development Engineer was also constantly stretched for funds. He and Varley (500) were really decent blokes - Cummins should have "bought" them!

yes the 680 came in a variety of configurations and had quite a long production life!

Bamford the Development Engineer was also constantly stretched for funds. He and Varley (500) were really decent blokes - Cummins should have "bought" them!

Yeah,that's them - but I don't remember them being hard to start.Getting them out of the workshop on a winter morning was a tearful exercise,there were clouds of acidic white smoke,and you had to run them up to 80psi to get the spring brakes to release.Tears would be streaming out of your eyes,just part of a normal working day.

I can't imagine one pulling a train,although they were more likely railcars.The nail in the coffin for the old Leylands (up to LAD cab) was not so much that they couldn't pull a load,but when our roads got better and speeds higher,they were just too slow.Some could only do 35mph,and most were on the govenor at 50mph.Driving LAD cab Hippo's and Octopus with a 680 and 6 speed/2 speed was a wonderful experience for a lad just out of his teens....

I can't imagine one pulling a train,although they were more likely railcars.The nail in the coffin for the old Leylands (up to LAD cab) was not so much that they couldn't pull a load,but when our roads got better and speeds higher,they were just too slow.Some could only do 35mph,and most were on the govenor at 50mph.Driving LAD cab Hippo's and Octopus with a 680 and 6 speed/2 speed was a wonderful experience for a lad just out of his teens....

Hi,

Silk - I drove a few Leyland prototyes at Leyland's Test Track in England. Some drove very well!!

One problem they had was insufficient airflow through the Cab's tunnel. This caused many overheating issues especially as turbochargers were installed and GVMs increased etc.

Yes, airbrakes were a novelty in NZ in the 1950s-1960s. They sure revolutionised truck braking systems and vehicle safety

Silk - I drove a few Leyland prototyes at Leyland's Test Track in England. Some drove very well!!

One problem they had was insufficient airflow through the Cab's tunnel. This caused many overheating issues especially as turbochargers were installed and GVMs increased etc.

Yes, airbrakes were a novelty in NZ in the 1950s-1960s. They sure revolutionised truck braking systems and vehicle safety

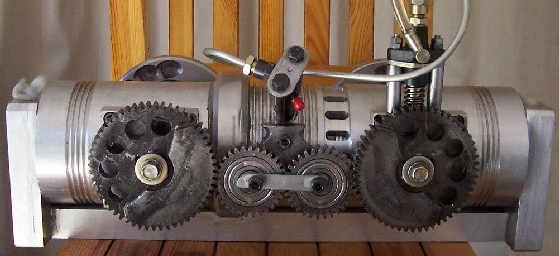

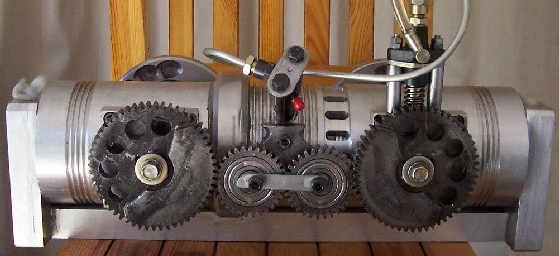

Here are the internal parts of the PatOP opposed piston, single crankshaft engine:

Bore: 79.5mm

Stroke: 64+64=128mm

Displacement: 635cc

Compression ratio: 17

Scavenging pump bore: 130mm (1.34 scavenging ratio)

Total engine height: 500mm

Total engine weight (without the flywheel): less than 20Kp

It is an:

opposed-piston,

two-stroke,

single-cylinder,

single-crankshaft,

full-balanced (vibration free),

cross-head,

direct-injection Diesel engine,

with built-in "volumetric" (for a wider rev range and flat torque curve) scavenging pump,

with four-stroke-like lubrication,

and with some 35% as compared to the conventional, or some 20% as compared to the Junkers-Doxford and to the OPOC of EcoMotors, additional time for the injection and combustion of the fuel.

This

is from the QuickTime video of the PatOP prototype running on Diesel fuel, free standing on a Desk

For more go to : PatOP engine

Here is the gif animation of the old Commer TS

The controllable windows exe animation is at Commer TS exe animation

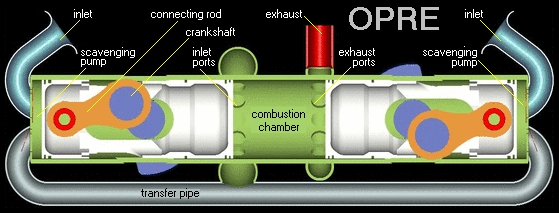

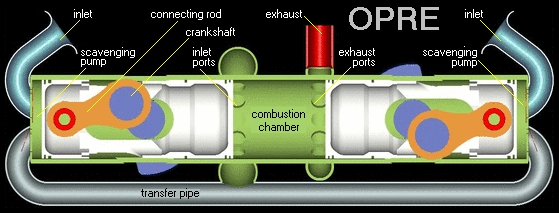

And here is the two crankshaft OPRE opposed piston engine:

Videos etc for the OPRE engine at OPRE engine

The piston dwell at the Combustion Dead Center (CDC) of the PatOP (and of the OPRE) engine is significantly longer than the piston dwell at the Combustion Dead Center of the conventional engine, as shown in the plot and the gif animation below:

Thanks

Manousos Pattakos

Bore: 79.5mm

Stroke: 64+64=128mm

Displacement: 635cc

Compression ratio: 17

Scavenging pump bore: 130mm (1.34 scavenging ratio)

Total engine height: 500mm

Total engine weight (without the flywheel): less than 20Kp

It is an:

opposed-piston,

two-stroke,

single-cylinder,

single-crankshaft,

full-balanced (vibration free),

cross-head,

direct-injection Diesel engine,

with built-in "volumetric" (for a wider rev range and flat torque curve) scavenging pump,

with four-stroke-like lubrication,

and with some 35% as compared to the conventional, or some 20% as compared to the Junkers-Doxford and to the OPOC of EcoMotors, additional time for the injection and combustion of the fuel.

This

is from the QuickTime video of the PatOP prototype running on Diesel fuel, free standing on a Desk

For more go to : PatOP engine

Here is the gif animation of the old Commer TS

The controllable windows exe animation is at Commer TS exe animation

And here is the two crankshaft OPRE opposed piston engine:

Videos etc for the OPRE engine at OPRE engine

The piston dwell at the Combustion Dead Center (CDC) of the PatOP (and of the OPRE) engine is significantly longer than the piston dwell at the Combustion Dead Center of the conventional engine, as shown in the plot and the gif animation below:

Thanks

Manousos Pattakos

Apparently there's another startup working on a new opposed piston engine.

The engine uses sleeve valves with variable timing and compression that will allow it to use diesel, gasoline or propane.

It will also butter your bread and do your laundry.

The engine uses sleeve valves with variable timing and compression that will allow it to use diesel, gasoline or propane.

It will also butter your bread and do your laundry.

This could go under lawn and garden stuff, but figured it might merit going here. Homebuilt opposed piston engine using two briggs and stratton engines. Pretty slick.

Here is how it's put together.

Here is how it's put together.

Last edited:

This guy also made a homemade sleeve valve engine. Pretty neat.

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 170

- Replies

- 84

- Views

- 2K

- Replies

- 10

- Views

- 6K

- Replies

- 30

- Views

- 1K