- Joined

- Aug 4, 2020

- Messages

- 557

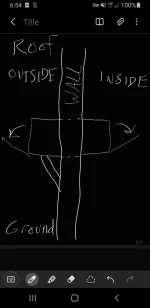

I've been brainstorming an unusual lock box setup for my shop. I have concrete block walls and I have an old unusable swamp cooler that I've been wanting to remove for years now. I recently realized I NEED a bin/box/shed/something to allow the delivery drivers to secure my parts in (mainly weather reasons). I'd like to remove my swamp cooler and put a double-sided 'drop box' in the empty hole. The best comparison I can make is to a large window A/C unit, but with the guts removed. I just don't know what is available or how to go about it. I made a few 5-minute sketches of the basic concept I'm after. I want a locking external hatch door, and a door (not sure yet if locking or not) for the inside as well. I want it to take up the entire wall hole if possible, but I need to take measurements. I want the doors to basically take the entire height and width of the box, because I need to fit large items through the doors such as large brake rotors, jugs of motor oil, 50lb bags of Oil Dri, etc. Any ideas besides finding a local welder and paying for custom creativity? Any help or advice is appreciated. Here's the quick sketches: