JHZR2

Staff member

Hopefully this is easy...

I’d like a pump in park valve body for the 47RE in my Ram. I had thought that meant a replacement $600 valve body. I was hesitant because of the fact that I’m not doing power increase mods, and the AT was replaced within 10k before I bought it.

I found that a $40-ish lube regulated pressure regulating valve, and a $20-ish manual valve from Sonnax would get me what I want. I want to do a filter Replacement on the rebuilt AT, so I’m interested in this option.

Apparently these two items are the same parts for all the torqflite transmissions dating back to ~1978... so I’m hoping someone has experience. I’d like to swap those parts. But I’ll be doing it on my back, in the wintertime. I’m really not interested in pulling the valve body, wrestling with connectors and the parking rod, etc.

Does anyone know if these two items can be replaced with the valve body in place, without removing it? Dropping it via release of a few of the bolts is one thing... hoping to not mess with the whole thing. I just am not a fan of messing with the innards of ATs.

Any experience?

www.sonnax.com

www.sonnax.com

www.sonnax.com

www.sonnax.com

I’d like a pump in park valve body for the 47RE in my Ram. I had thought that meant a replacement $600 valve body. I was hesitant because of the fact that I’m not doing power increase mods, and the AT was replaced within 10k before I bought it.

I found that a $40-ish lube regulated pressure regulating valve, and a $20-ish manual valve from Sonnax would get me what I want. I want to do a filter Replacement on the rebuilt AT, so I’m interested in this option.

Apparently these two items are the same parts for all the torqflite transmissions dating back to ~1978... so I’m hoping someone has experience. I’d like to swap those parts. But I’ll be doing it on my back, in the wintertime. I’m really not interested in pulling the valve body, wrestling with connectors and the parking rod, etc.

Does anyone know if these two items can be replaced with the valve body in place, without removing it? Dropping it via release of a few of the bolts is one thing... hoping to not mess with the whole thing. I just am not a fan of messing with the innards of ATs.

Any experience?

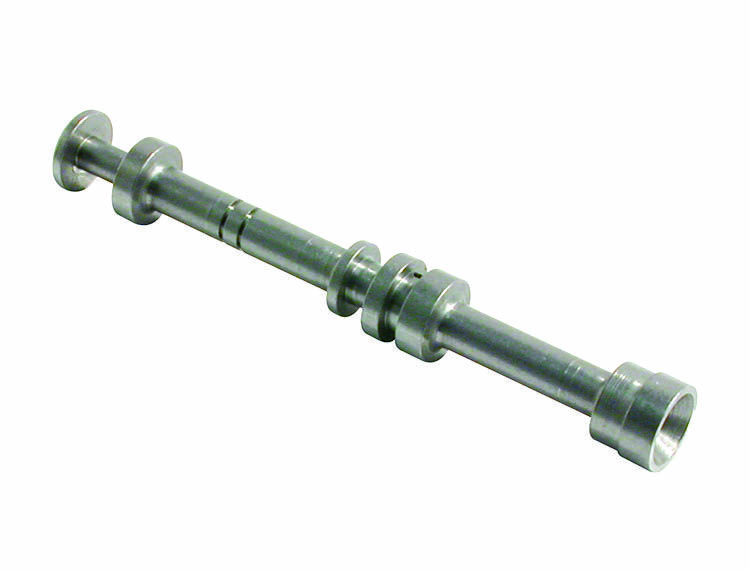

Lube Regulated Pressure Regulator Valve - 22771A-02K

Enhance converter charge and prevent drain back problems. Improves converter feed/lube oil flow. Fits '78-Later 48RE units. Part # 22771A-10K.

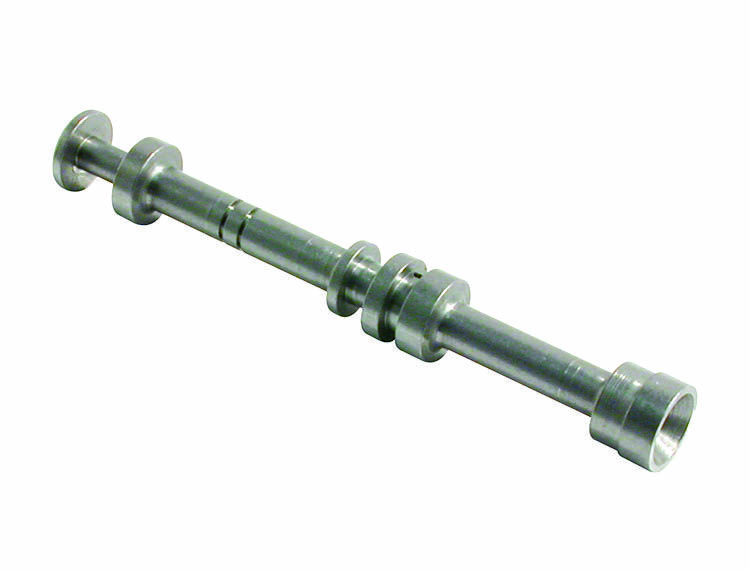

Manual Valve - 22771-09

Introduce converter/cooler charge in Park in various Chrysler transmissions with Sonnax manual valve #22771-09. Recommended to install alongside #22771A-02K.