I repowered my nephews' minibike with a 79cc HF Predator engine.

The OEM engine had less than 100 hours and OCI was about every 25hrs with Rotella T 15w-40.

My father was building a twin-turbo 632ci BBC for a customer while I borrowed some workspace to swap the engine. I took the liberty of giving the HF engine a full teardown for inspection and re assembly. We gave the head a light port and polish job. And used some left over Cerakote coatings on the head, valves, and piston. The piston top, combustion chamber, and valve tops received V136 thermal barrier coating. The valve stems and piston skirt received C110 micro slick dry film ceramic coating. I also posted this in the Small Engine OC thread, but forgot to mention I polished the connecting rod.

Too bad I did not take pics of this build as my cell was dead. It was pretty cool.

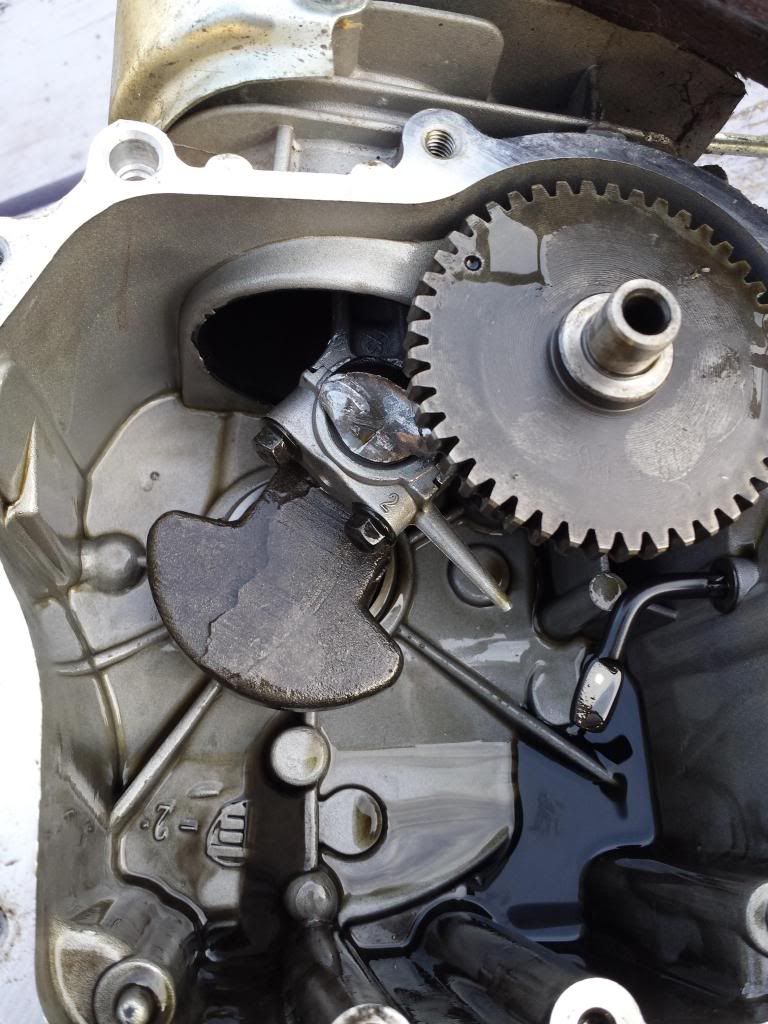

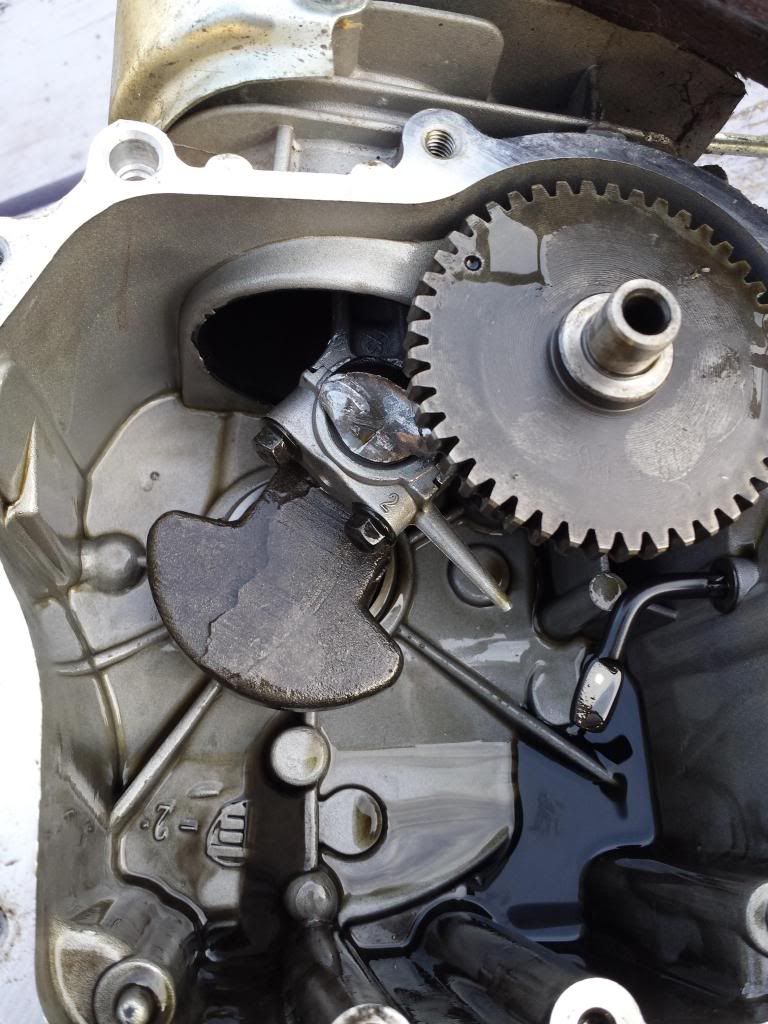

I did take pics of the OEM engine. All other areas of the OEM engine were in great shape, like-new condition, including the piston, bore, bearings, and valvetrain.

My guess is it failed due to inferior materials used in the Chinese clone. Their machining looks great, but I think they need help in the metallurgy arena. After tearing down this engine I regret not shot-peening the Preadator's crankshaft.

Anyone else have ideas for this type of failure?

Intake Lobe:

Exhaust Lobe:

Lifters, Intake Left, Exhaust Right:

Crankshaft, PTO side:

Crankshaft, Flywheel Side:

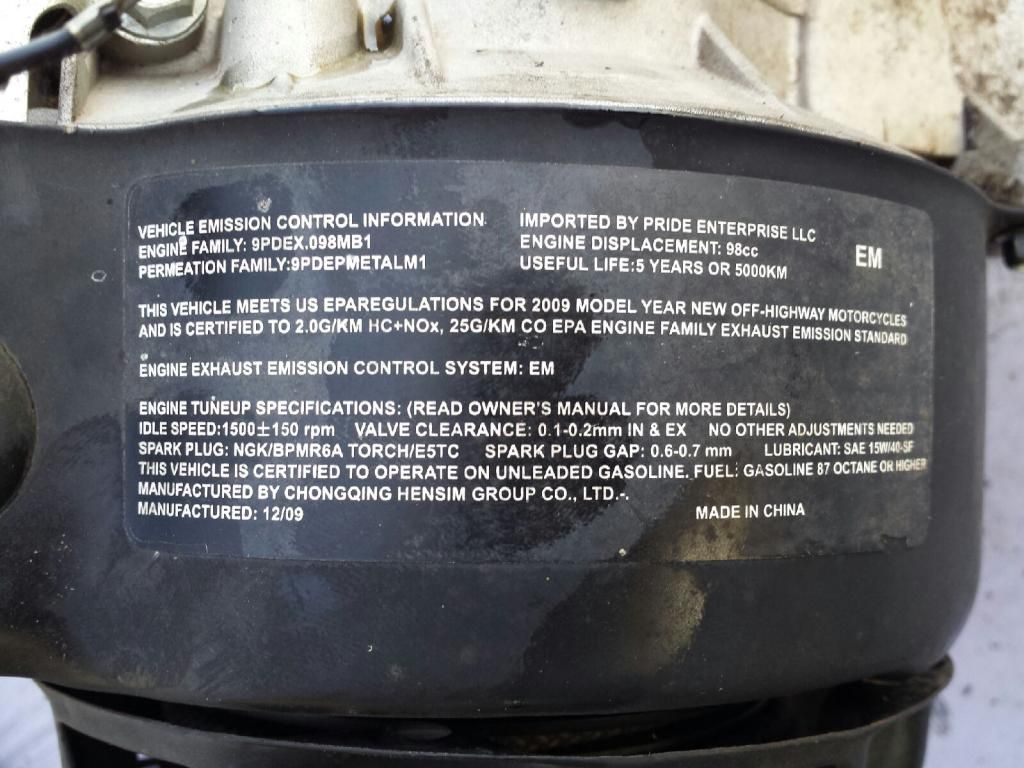

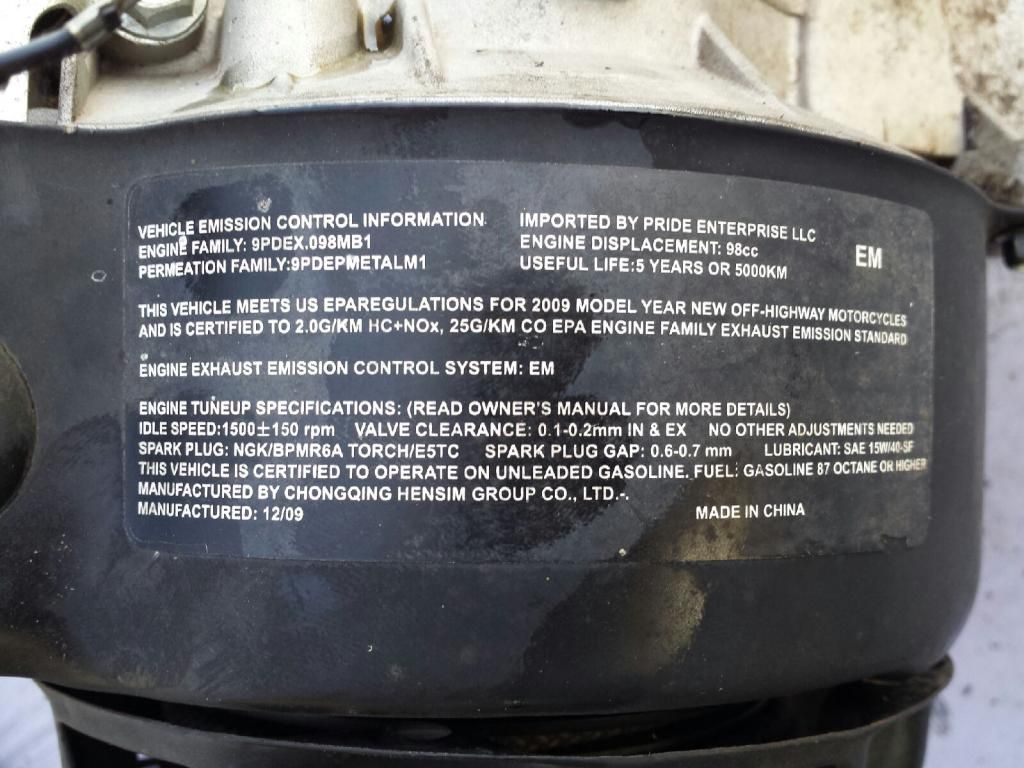

Engine Label:

The OEM engine had less than 100 hours and OCI was about every 25hrs with Rotella T 15w-40.

My father was building a twin-turbo 632ci BBC for a customer while I borrowed some workspace to swap the engine. I took the liberty of giving the HF engine a full teardown for inspection and re assembly. We gave the head a light port and polish job. And used some left over Cerakote coatings on the head, valves, and piston. The piston top, combustion chamber, and valve tops received V136 thermal barrier coating. The valve stems and piston skirt received C110 micro slick dry film ceramic coating. I also posted this in the Small Engine OC thread, but forgot to mention I polished the connecting rod.

Too bad I did not take pics of this build as my cell was dead. It was pretty cool.

I did take pics of the OEM engine. All other areas of the OEM engine were in great shape, like-new condition, including the piston, bore, bearings, and valvetrain.

My guess is it failed due to inferior materials used in the Chinese clone. Their machining looks great, but I think they need help in the metallurgy arena. After tearing down this engine I regret not shot-peening the Preadator's crankshaft.

Anyone else have ideas for this type of failure?

Intake Lobe:

Exhaust Lobe:

Lifters, Intake Left, Exhaust Right:

Crankshaft, PTO side:

Crankshaft, Flywheel Side:

Engine Label: