Originally Posted By: StevieC

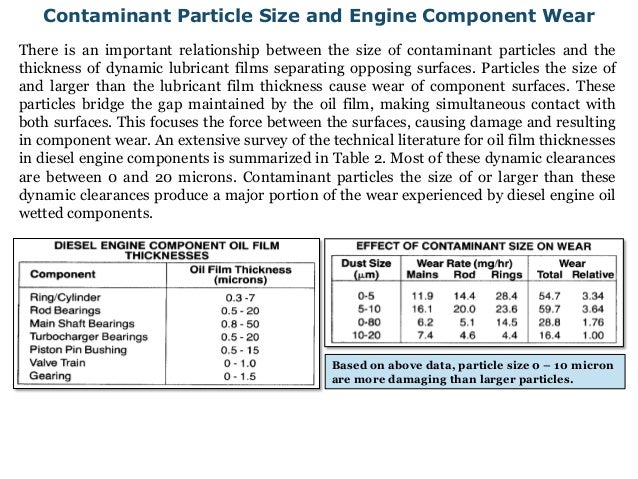

To get the stuff smaller than 20 micron is done by either changing the oil more frequently through regular OCI's or by using Bypass filtration which then takes everything out of the oil up to 1-2 micron level.

Don't really need a by-pass filter unless you're going for relatively super long OCIs like the "big truckers" do. IMO, doing 10K mile OCIs with synthetc oil and a filter that's 99% at 20u is going to keep wear way down.

To get the stuff smaller than 20 micron is done by either changing the oil more frequently through regular OCI's or by using Bypass filtration which then takes everything out of the oil up to 1-2 micron level.

Don't really need a by-pass filter unless you're going for relatively super long OCIs like the "big truckers" do. IMO, doing 10K mile OCIs with synthetc oil and a filter that's 99% at 20u is going to keep wear way down.