You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can I run dex6 in my th400.

- Thread starter joegreen

- Start date

- Status

- Not open for further replies.

Making gradual progress:

1. Rear case rollerized

2. Pump and valves reassembled

3. Valve body with new electronics reassembled

4. Full circlip intermediate snap ring ready

5. About 75% into replacing all bushings

6. Mysterious bushing-like debris found to be front planet side shim - replacement assy. found

7. So far unable to locate just the stiffer version of Intermediate and Direct springs without having to buy a kit with duplicate parts

1. Rear case rollerized

2. Pump and valves reassembled

3. Valve body with new electronics reassembled

4. Full circlip intermediate snap ring ready

5. About 75% into replacing all bushings

6. Mysterious bushing-like debris found to be front planet side shim - replacement assy. found

7. So far unable to locate just the stiffer version of Intermediate and Direct springs without having to buy a kit with duplicate parts

Originally Posted By: JiL

Making gradual progress:

So far unable to locate just the stiffer version of Intermediate and Direct springs without having to buy a kit with duplicate parts

The stock intermediate spring retainer will not hold up to high rate springs, I have seen them fail with stock springs, IF you have access to a TH400 Retainer....You can use it & buy the springs separate,HERE

High Rate direct springs "MAY" be able to be used on your stock spring retainer......Due to manufacturing variations in the Springs, Top retainer, & Bottom retainer, It can turn into a challenging endeavor trying to fit the ID of the springs into the top & bottom registers.

IF you have access to a TH400 Direct/Forward Top Retainer....Things will be easier(You will only have to modify the Bottom retainer if modifications are necessary)

Separate direct high rate springs HERE

Let's address the shortcomings of production 4L80E Direct Pistons (This also applies to the Forward Piston).....

'91-'96 Aluminum Pistons should NEVER be used in a high performance application, They can break when subjected to higher than stock line pressure. Has a thin "Work Surface" that is undesirable for maximum clamping of the clutch.

'97-Current Bonded Steel pistons do not have breakage issues, But have the same thin work surface issue.

A Aluminum TH400 Direct Piston along with matching retainer is the BEST combination to use(Outside of a Billet Piston) in a performance 4L80E, Has DEEP spring pockets, Wide work surface, And will NOT break.

**A TH400 Forward/Direct Piston can be used in the 4L80E Forward Drum IF the press in center bonded lip seal is removed, TH400 forward & direct pistons have different "Work Surface" heights from each other.....

Using a TH400 Forward/Direct Piston in a 4L80E Forward Drum WILL require machining to fit a Wave & all 5 Frictions. The Forward Clutch is less important than the Direct as far as maximum clamping being needed, Just information for you.

Enough of my rambling.....

In the end I suggest buying the kit's for the Intermediate & Direct Clutch & move on, But it's your build & money.

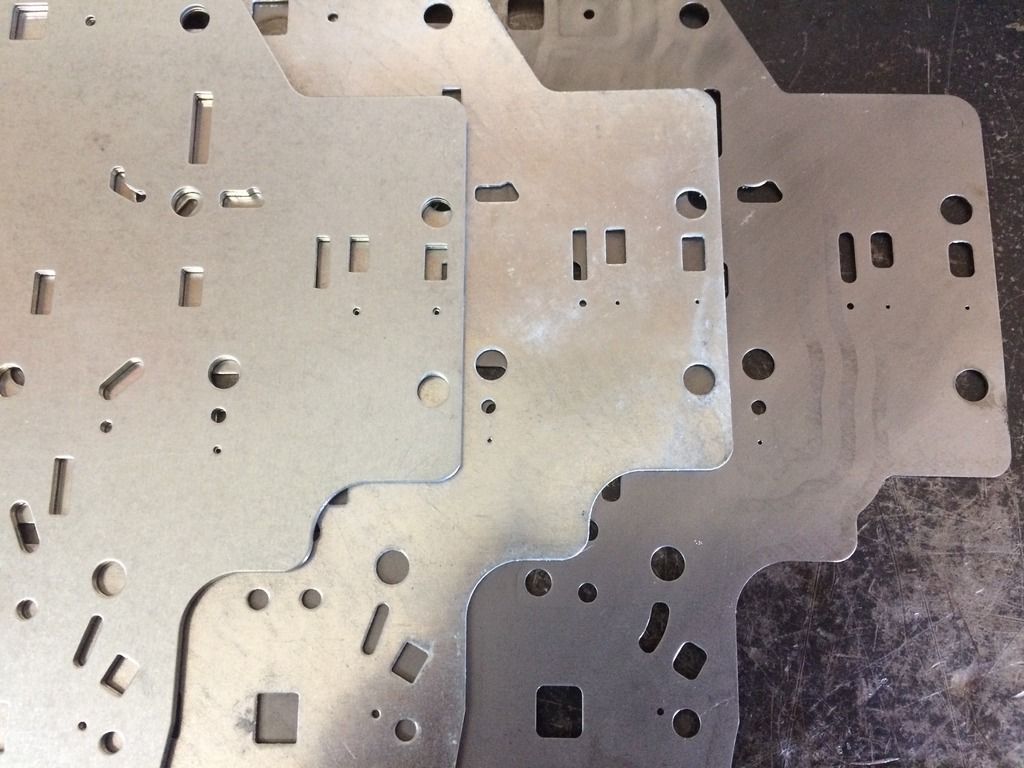

4L80E Direct/Forward Retainer picture, As you can see the spring is retained by a stamped boss on the top & Tap on the bottom, They are a very tight fit with a stock spring.

Making gradual progress:

So far unable to locate just the stiffer version of Intermediate and Direct springs without having to buy a kit with duplicate parts

The stock intermediate spring retainer will not hold up to high rate springs, I have seen them fail with stock springs, IF you have access to a TH400 Retainer....You can use it & buy the springs separate,HERE

High Rate direct springs "MAY" be able to be used on your stock spring retainer......Due to manufacturing variations in the Springs, Top retainer, & Bottom retainer, It can turn into a challenging endeavor trying to fit the ID of the springs into the top & bottom registers.

IF you have access to a TH400 Direct/Forward Top Retainer....Things will be easier(You will only have to modify the Bottom retainer if modifications are necessary)

Separate direct high rate springs HERE

Let's address the shortcomings of production 4L80E Direct Pistons (This also applies to the Forward Piston).....

'91-'96 Aluminum Pistons should NEVER be used in a high performance application, They can break when subjected to higher than stock line pressure. Has a thin "Work Surface" that is undesirable for maximum clamping of the clutch.

'97-Current Bonded Steel pistons do not have breakage issues, But have the same thin work surface issue.

A Aluminum TH400 Direct Piston along with matching retainer is the BEST combination to use(Outside of a Billet Piston) in a performance 4L80E, Has DEEP spring pockets, Wide work surface, And will NOT break.

**A TH400 Forward/Direct Piston can be used in the 4L80E Forward Drum IF the press in center bonded lip seal is removed, TH400 forward & direct pistons have different "Work Surface" heights from each other.....

Using a TH400 Forward/Direct Piston in a 4L80E Forward Drum WILL require machining to fit a Wave & all 5 Frictions. The Forward Clutch is less important than the Direct as far as maximum clamping being needed, Just information for you.

Enough of my rambling.....

In the end I suggest buying the kit's for the Intermediate & Direct Clutch & move on, But it's your build & money.

4L80E Direct/Forward Retainer picture, As you can see the spring is retained by a stamped boss on the top & Tap on the bottom, They are a very tight fit with a stock spring.

Last edited:

So I took apart the direct drum today and i think i found why it lost reverse and third. There was a seal that was blown out so im guessing it couldnt apply pressure. Anyway i also noticed that i have space for 16 springs on the drum but only 12 were installed. Is that normal or is there supposed to be 16? Also some of the springs were shorter than than the others and were slightly shinier. Maybe someone replaced them?

I heard you can put a 4l80e direct drum in a th400. Should i just purchase this? http://www.ebay.com/itm/4L80E-Transmissi...-/131464696949. or just buy a piston. http://www.ebay.com/itm/Turbo-400-Aluminum-Direct-Piston-w-Check-Ball-TH400-/122446876147?hash=item1c82670df3:g:WcsAAOSwGy5Y8Mjq&vxp=mtr. The drum has an 8 element sprag. Should i just buy a piston or should i upgrade to a drum with a 34 element sprag. This is not a high hp truck. Its just used to get around and plow in the winter.

Last edited:

Yes, A 4L80E direct drum is a drop-in replacement, It looks like that drum in the link has a return spring assembly & a "Molded" piston.....It may not have the work surface of a TH400 aluminum piston, But they do not break like the TH400 steel pistons! You will get all 16 return springs, Upgrade the sprag, & a spiro-lock sprag retainer. I would buy the 4L80E drum!

The TH400 piston in the link has a checkball, & your drum has a checkball. You need one or the other....Not both! So if you bought that piston you would need to block the checkball hole with a set screw or a cup plug.

At the factory....Some TH400 were produced with 2 springs missing from the direct & forward return spring assemblies, I have never seen 4 missing on a drum before.

Some builders get the Direct & Forward springs mixed up, Or springs from different years.....HACKS!

I'm guessing your Forward Drum also has the same style piston in it, They can break just like the direct piston, Just a heads-up! You can use a "molded" 4L80E direct piston & return spring assembly in a TH400 forward drum, BUT I'm not sure how it will effect your clutch stack height, I can measure a 4L80E direct piston for you if needed?

I don't know of any source for factory TH400 return springs.

The TH400 piston in the link has a checkball, & your drum has a checkball. You need one or the other....Not both! So if you bought that piston you would need to block the checkball hole with a set screw or a cup plug.

At the factory....Some TH400 were produced with 2 springs missing from the direct & forward return spring assemblies, I have never seen 4 missing on a drum before.

Some builders get the Direct & Forward springs mixed up, Or springs from different years.....HACKS!

I'm guessing your Forward Drum also has the same style piston in it, They can break just like the direct piston, Just a heads-up! You can use a "molded" 4L80E direct piston & return spring assembly in a TH400 forward drum, BUT I'm not sure how it will effect your clutch stack height, I can measure a 4L80E direct piston for you if needed?

I don't know of any source for factory TH400 return springs.

The molded Direct piston from my 4L80 is about 0.650" from the back "feet" to the part that presses against the clutch pack.

Springs: https://www.wittrans.com/search?part=34974

Springs: https://www.wittrans.com/search?part=34974

I bought this direct drum. http://www.ebay.com/itm/4L80E-DIRECT-CLUTCH-DRUM-WITH-SPRAG-1997-UP-CHEVY-GMC-TRUCK-TRANSMISSION-/201694221576?hash=item2ef5e99508:g:68oAAOSwpLNYBhnA&vxp=mtr. It seemed like a good deal. comes with the springs and new borg warner clutches.

I think you made the right choice!

I have a few questions relating to the photos below. I the first photo is the springs i removed from the forward drum. 8 of the springs on the right are short and 4 springs on the left are tall. Arent they all supposed to be the same height?

The next picture is the springs from the direct drum. Its a little harder to see from the first picture but 8 springs on the right are tall and 4 springs on the left are short. I think someone has been in the transmission before and when they removed the springs they mixed them all together. If i take the 4 taller springs from the one group and the 4 shorter springs from the other group and swap them into the other group then i can make a complete set of 12 tall springs and another complete set of 12 short springs. I think thats probably how it was to begin with. Does that sound like a good idea?

Now in the atsg manual it says to place 14 springs into the spring pockets. Now i only have 12 of the tall springs and 12 of the short springs. clinebarger i thought you said i should put 16 springs onto all 16 pockets instead of just 14? Because i bought a new direct drum with the springs i only need to use the springs i have for the forward drum. Should i use all the tall springs and then use a few short ones or should i use all the short springs and fill in the extra spaces with a few tall ones on the forward drum?

Finally i took the clutches out of the direct drum. What is that black ring on half of the clutch surface? The forward drum clutches did not have that ring.

The next picture is the springs from the direct drum. Its a little harder to see from the first picture but 8 springs on the right are tall and 4 springs on the left are short. I think someone has been in the transmission before and when they removed the springs they mixed them all together. If i take the 4 taller springs from the one group and the 4 shorter springs from the other group and swap them into the other group then i can make a complete set of 12 tall springs and another complete set of 12 short springs. I think thats probably how it was to begin with. Does that sound like a good idea?

Now in the atsg manual it says to place 14 springs into the spring pockets. Now i only have 12 of the tall springs and 12 of the short springs. clinebarger i thought you said i should put 16 springs onto all 16 pockets instead of just 14? Because i bought a new direct drum with the springs i only need to use the springs i have for the forward drum. Should i use all the tall springs and then use a few short ones or should i use all the short springs and fill in the extra spaces with a few tall ones on the forward drum?

Finally i took the clutches out of the direct drum. What is that black ring on half of the clutch surface? The forward drum clutches did not have that ring.

Last edited:

Originally Posted By: JiL

I picked up a set of the high rate Intermediate and Direct springs from ckperformance, but found that while the Direct springs are much stiffer than the OEM springs, the Intermediates are actually softer.

Interesting, I have never found that to be the case, Please call Chris @ CK....They actually answer the phone!

I built 3 4L80E's this month for customers & my own personal 4L80E for my Camaro, 2 of the customers & mine have CK springs, And I built 1 with stock 4L80E springs & a TH400 retainer for a stock work truck. So it's pretty fresh in my mind. I install the retainer & snap ring by hand, The CK springs are always stiffer than stock springs.

Do you have a spring pressure gauge? I can measure the "weight" of a stock spring at installed height & we can compare notes.

The "free height" of my springs out of a '97 model are .951".

The springs themselves are not as important as the Retainer, The Center Support is stationary, So the Intermediates can't centrifugally apply like the Directs can.

Either someone has changed the springs in a past build or CK sent you the wrong spring.

Calculating spring rate/weight by hand is a little tricky.......Try assembling with the CK springs....Then with the old springs, This may give you a better feel.

I picked up a set of the high rate Intermediate and Direct springs from ckperformance, but found that while the Direct springs are much stiffer than the OEM springs, the Intermediates are actually softer.

Interesting, I have never found that to be the case, Please call Chris @ CK....They actually answer the phone!

I built 3 4L80E's this month for customers & my own personal 4L80E for my Camaro, 2 of the customers & mine have CK springs, And I built 1 with stock 4L80E springs & a TH400 retainer for a stock work truck. So it's pretty fresh in my mind. I install the retainer & snap ring by hand, The CK springs are always stiffer than stock springs.

Do you have a spring pressure gauge? I can measure the "weight" of a stock spring at installed height & we can compare notes.

The "free height" of my springs out of a '97 model are .951".

The springs themselves are not as important as the Retainer, The Center Support is stationary, So the Intermediates can't centrifugally apply like the Directs can.

Either someone has changed the springs in a past build or CK sent you the wrong spring.

Calculating spring rate/weight by hand is a little tricky.......Try assembling with the CK springs....Then with the old springs, This may give you a better feel.

- Status

- Not open for further replies.

Similar threads

- Replies

- 26

- Views

- 5K

- Replies

- 21

- Views

- 3K

- Replies

- 17

- Views

- 2K