Originally Posted By: Lt_Oli

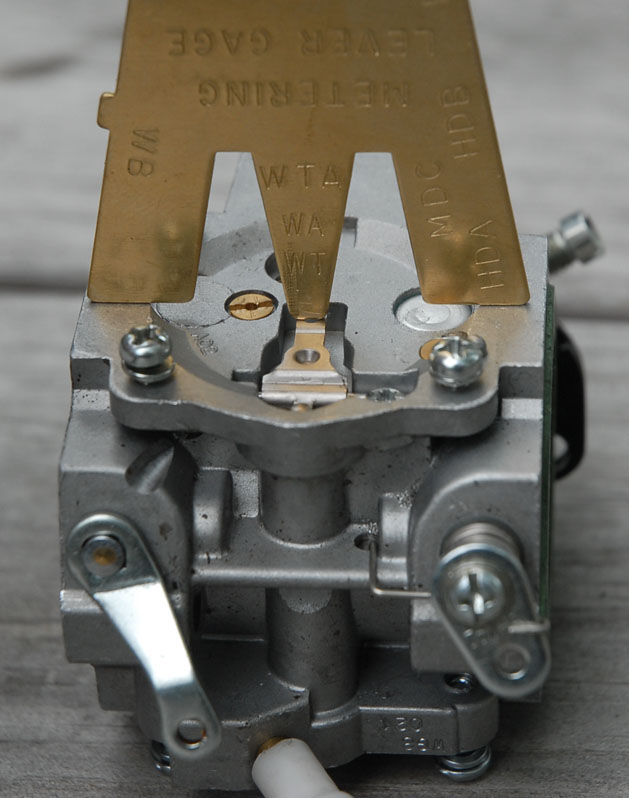

Check the Walbro site for your particular carb, and determine if there is a check valve in the primary metering circuit. This check valve can be jammed by blowing compressed air into the various holes and passages. Try brake cleaner. As a general rule, as you spray the cleaner into one hole, you should see it exit from another.

Replace the fuel lines and impulse line if so equipped. They can become soft overtime and collapse as the saw revs.

When you installed the carb kit, did you replace the gaskets and diaphragms in the correct order? Carb kits work most of the time, but not always. You may need to replace the carb

When I spray WD-40 through the mixture screw holes. It comes out in two places. The intake holes in the fuel chamber and the holes in the venturi.

Impulse line and fuel line are both in good shape.

Gaskets installed according to instructions. On the fuel output side, I have the plate, the metering diaphragm then the gasket. On the fuel intake side it's the cover, the gasket then the fuel pump diaphragm.

This is a very perplexing challenge to say the least.

Going to give everything a good once over then probably look for a new carb or just give it up and pick up another inexpensive used saw in good shape.

At the very least, it's been a very good learning experience.