You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why isn't there a manual transmission standard shift pattern design?

- Thread starter CharlesInCharge

- Start date

Saw an interesting one at a truck show on Saturday. Truck was an old brockway , gas engine with a clark 5 speed OD trans.

2 OD R

|--|-----

3 4 1

I would get really confused

2 OD R

|--|-----

3 4 1

I would get really confused

CharlesInCharge

Thread starter

Saw an interesting one at a truck show on Saturday. Truck was an old brockway , gas engine with a clark 5 speed OD trans.

2 OD R

|--|-----

3 4 1

I would get really confused

What the...

Apparently they wanted to sell a lot of replacement transmissions. I guess that's a business strategy.

More like they understood that 1st was rarely used, so the extreme dog leg is not a problem, and their probably professional drivers would have a certain level of proficiency.What the...

Apparently they wanted to sell a lot of replacement transmissions. I guess that's a business strategy.

Last edited:

More like they understood that 1st was rarely used, so the extreme dog leg is not a problem, and their probably professional drivers would have a certain level of proficiency.

Setup so you skip 1st and 3rd

Doesn’t make much sense

More like they understood that 1st was rarely used, so the extreme dog leg is not a problem, and their probably professional drivers would have a certain level of proficiency.

I bet it was a real granny gear, but on a truck that big powered by a flathead inline 6 gas engine, I think you'd need all the reduction possible to get that much weight moving!

CharlesInCharge

Thread starter

More like they understood that 1st was rarely used, so the extreme dog leg is not a problem, and their probably professional drivers would have a certain level of proficiency.

I guess you'd have to be a professional to get that Dr. Seuss designed transmission working.

Or maybe it's the ultimate theft prevention. Remove the gear-shift pattern entirely to get a real box of surprises for the driver.

Brockway made heavy duty trucks, so… yes they would have been professional drivers.I guess you'd have to be a professional to get that Dr. Seuss designed transmission working.

CharlesInCharge

Thread starter

Brockway made heavy duty trucks, so… yes they would have been professional drivers.

The missed point, whether inadvertent or being obtuse, is why would you design something overly needlessly complex even for professionals. I assume you want them focused on the task of safely driving without accidents or killing pedestrians.

I'm further assuming they don't hide poison darts in the cab, or make drivers sit on broken glass, or design the steering wheel as a triangle or put square wheels on the vehicle... If I'm designing a product, I want people to be able to use it as easily and error free as possible.

You’re assuming they did it deliberately. How do you that this oddball pattern was not to reduce parts count and/or strengthen the transmission? Maybe 1st is actually a compound gear ratio.The missed point, whether inadvertent or being obtuse, is why would you design something overly needlessly complex even for professionals. I assume you want them focused on the task of safely driving without accidents or killing pedestrians.

I'm further assuming they don't hide poison darts in the cab, or make drivers sit on broken glass, or design the steering wheel as a triangle or put square wheels on the vehicle... If I'm designing a product, I want people to be able to use it as easily and error free as possible.

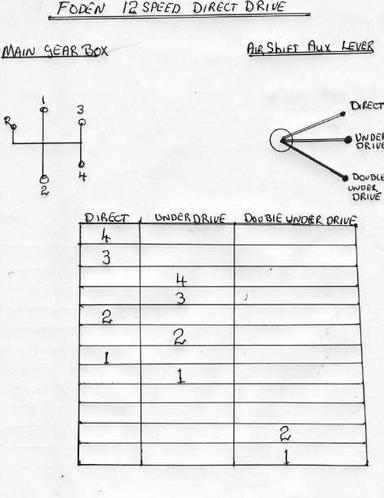

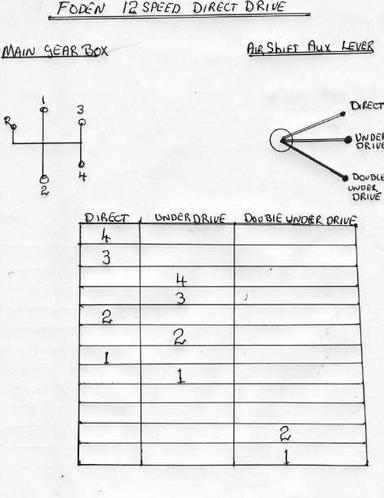

See if you can figure out what this guy is doing. Never driven one myself, but served my time with a guy who had worked for Fodens, so know what is going on.

Last edited:

I am not familiar w/ Brockway's, but I would guess that pattern makes sense for how the manufacturer anticipated the truck would be utilized. 1st as a 'granny gear' was rarely used, so it is out of the main pattern. I would suspect that once the vehicle was rolling, most of the shifting was in and out of OD. forward and back, with 3rd and 2nd used as conditions warranted. Again, I am not an expert but I suspect this is a case of optimizing the pattern towards the use. One standard pattern would not be optimal for all use cases.The missed point, whether inadvertent or being obtuse, is why would you design something overly needlessly complex even for professionals. I assume you want them focused on the task of safely driving without accidents or killing pedestrians.

I'm further assuming they don't hide poison darts in the cab, or make drivers sit on broken glass, or design the steering wheel as a triangle or put square wheels on the vehicle... If I'm designing a product, I want people to be able to use it as easily and error free as possible.

Similar threads

- Replies

- 75

- Views

- 3K

- Replies

- 12

- Views

- 2K

- Replies

- 118

- Views

- 5K

- Replies

- 27

- Views

- 2K