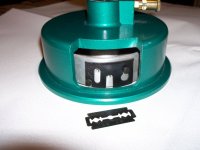

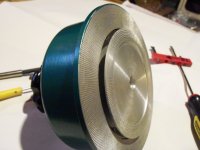

Tool consists of two parts, the outer housing and the inner working part that is rotated by the black plastic knob.There are 4 razor blades attached that cut. The cutting edges line up radially with the edge of the aluminium cone shown in the second photo, but is recessed about 4 mm above the edge of the cone. One of the cutting edges can be seen at the bottom of the 3rd photo, also in the 4th photo at the top. The bottom surfaces of both the main tool and the inner half are textured, looks like they are meant to grip. Cone is spring loaded, it moves in and out. Brass plunger is a lock, once locked the inner half cannot be depressed. Well made tool and looks like it has never been used since there is no debris whatsoever inside the tool

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Is this Tool?

- Thread starter George7941

- Start date

Scoring of wall paper for removal ?

George7941

Thread starter

As to where it came from, your guess is as good as mine. I work at a moving company and we do a lot of estate moves upon the passing of the resident and we end up with a lot of oddball stuff. The guys in the warehouse were guessing as to what it is, so I thought the collective wisdom at Bitog, which is considerable, might solve the puzzle. I do not know which particular move produced this tool.

If it was a circle paper cutter the inner half would not have the textured grippy surface, same for it scoring wallpaper. The inner half rotates to cut. The other puzzling fact is that all four blades are recessed behind the center cone, so there is no way for it to cut paper. Looking at the four mounting screws for each blade indicates that the blades are where they are designed to be at.

The material would have to be soft (pasta?) for it to extrude past the center cone upon application of pressure and be cut by the blades.

If it was a circle paper cutter the inner half would not have the textured grippy surface, same for it scoring wallpaper. The inner half rotates to cut. The other puzzling fact is that all four blades are recessed behind the center cone, so there is no way for it to cut paper. Looking at the four mounting screws for each blade indicates that the blades are where they are designed to be at.

The material would have to be soft (pasta?) for it to extrude past the center cone upon application of pressure and be cut by the blades.

AutoMechanic

Site Donor 2024

I have no idea. Never seen anything like it.

It's a tool used to cut precise circular samples of material. For example:

GSM Round Cutter Manufacturer and Supplier (prestogroup.com)

GSM Round Cutter Manufacturer and Supplier (prestogroup.com)

Just a guess, but I think it could be used to cut a dryer vent in plexiglass, or maybe even score glass so a circle for a dryer vent can be tapped out. Check the diameter of the aluminum flex hose or exit pipe assembly of clothes dryers vs the tool, and see if the circle it makes is just a little bit larger than the diameter of those parts.

George7941

Thread starter

You are right, a material circle cutter is what it is. The Presto tool linked to is even the same colour!It's a tool used to cut precise circular samples of material. For example:

GSM Round Cutter Manufacturer and Supplier (prestogroup.com)

I checked again, the cone does retract when the tool is pushed on from the top. that brings the four blades into contact with the material being cut.

Still puzzled as to why the center cone is knurled at the bottom. You would expect it to be as smooth as possible because it has to slide over the material being cut. It will remain a mystery.

The knurling holds the fabric down, both inside and outside of the cut line for a clean accurate cut. Those blades cut a circle of fabric sample used to determine overall product weight/density (Grams per Square Meter). There is no sliding action. Check out GSM Round Cutter on Google and especially YouTube.Still puzzled as to why the center cone is knurled at the bottom. You would expect it to be as smooth as possible because it has to slide over the material being cut. It will remain a mystery.

What does Exit32 win?????

Last edited:

Anyone else follow the link and learn a new word; 'Grammage'? Thank you!

George7941

Thread starter

Now that I know what the tool is for, I put it up for sale

www.kijiji.ca

www.kijiji.ca

I am going to be pleasantly surprised if I do sell it in a depressed pandemic troubled market.

Kijiji - Buy, Sell & Save with Canada's #1 Local Classifieds

Visit Kijiji Classifieds to buy, sell, or trade almost anything! New and used items, cars, real estate, jobs, services, vacation rentals and more virtually anywhere.

I am going to be pleasantly surprised if I do sell it in a depressed pandemic troubled market.

Similar threads

- Replies

- 21

- Views

- 910

- Replies

- 63

- Views

- 6K

- Replies

- 51

- Views

- 3K