GON

$100 Site Donor 2024

United Airlines Boeing 787-9 operating flight UA839 from Los Angeles to Sydney has diverted to Pago Pago in American Samoa. The aircraft has a potential engine oil leak and landed at Pago Pago.

United has scheduled a rescue operation as follows - The 787-9 N24979 currently flying from Houston to Sydney as UA101 will land in Sydney and turn around and return to Pago Pago to collect the passengers stranded by the diversion of UA839. The rescue flight will be trackable as UA2795. https://www.flightradar24.com/data/flights/ua2795

Passengers are likely to have a wait in Pago Pago of 12 hours. The 31 Dec 2022 Sydney to Los Angeles UA842 service is now Cancelled

The diverted A/C on the ground is BOEING 787 - MSN 37814 N38955

Serial number 37814 LN:297

Type 787-9

First flight date 30/04/2015

Test registration

Plane age 7.7 years

Seat configuration C48 Y204 Seat

Hex code A47FDE

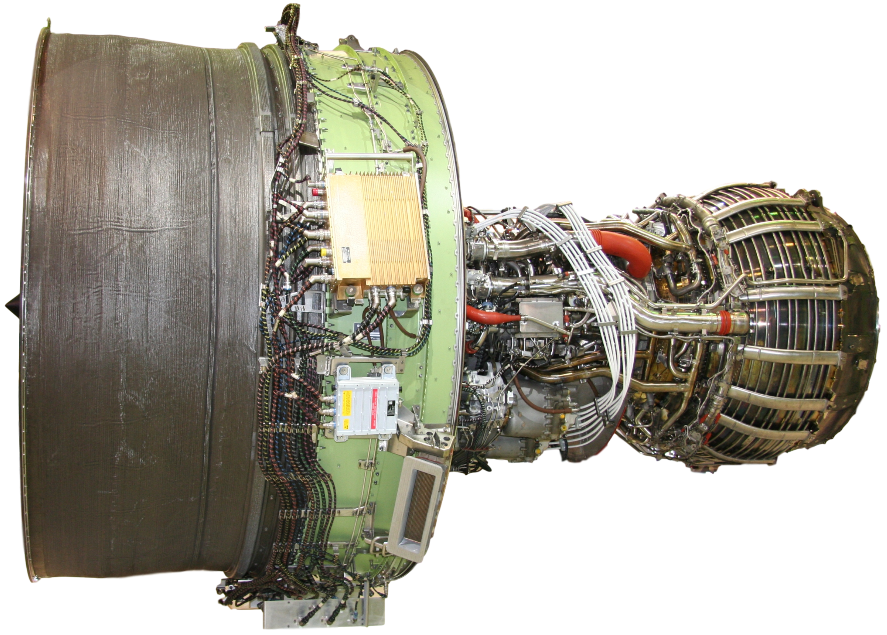

Engines 2 x GEnx-1B

United has scheduled a rescue operation as follows - The 787-9 N24979 currently flying from Houston to Sydney as UA101 will land in Sydney and turn around and return to Pago Pago to collect the passengers stranded by the diversion of UA839. The rescue flight will be trackable as UA2795. https://www.flightradar24.com/data/flights/ua2795

Passengers are likely to have a wait in Pago Pago of 12 hours. The 31 Dec 2022 Sydney to Los Angeles UA842 service is now Cancelled

The diverted A/C on the ground is BOEING 787 - MSN 37814 N38955

Serial number 37814 LN:297

Type 787-9

First flight date 30/04/2015

Test registration

Plane age 7.7 years

Seat configuration C48 Y204 Seat

Hex code A47FDE

Engines 2 x GEnx-1B