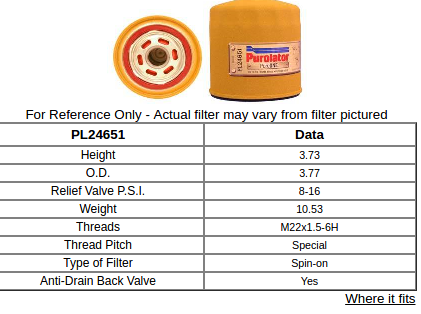

Since everyone loved the thread about the Motorcraft thread-end bypass valve I thought I would share some pics of a Purolator dome-end bypass valve from a recently cut PureOne PL24651 (equivalent to a FL820S). Three things struck me. First, the spring is really hard to open--couldn't pry it up with my fingertips alone--required sticking a screwdriver blade under and then I could pry it open with force. Second, that thing doesn't open very wide ever I imagine. There isn't a lot of travel available. Probably just opens a sliver once in a great while in real-world use. Third, there would have to be a lot of sludge in the can before it would ever get close to the opening. It's hard to imagine there is any significant advantage to a thread-end bypass valve.

Last edited: