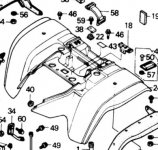

Can anyone suggest a way to repair this plastic piece? It is the side panel on my 1991 Honda 300 4x4 ATV. The panel attaches to the gas tank by way of the slide in connector. It appears as over time a stress crack has formed in the right angle of the section. Buying a new section is not realistic as it is a part of the entire rear fender. All suggestions welcome.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Plastic Repair

- Thread starter pburchett

- Start date

I usually roughen those kinds of cracks and apply cloth or fiberglass cloth on the inside saturated in 30 min epoxy. You can't get a good bond just by gluing the edge, it won't hold up.

I have fixed a few body panels using the following method. This works well on polycarbonate cycle panels YMMV on polypropylene where glues tend not to stick method 2.

On the back hidden side roughen the surface larger than the crack with samdpaper. Then get some cyanoacrylate glue from hobby store or "Super Glue" from walmart. put a thin puddle of CA onto the spot then using fingers or sifter sprinkle baking soda onto the glue to coat it evenly. The glue will immediately soak up the BS and heat up. you may hear some crackling and you'll see the glue will look dry. repeat the process making thin layers until you have a large "Patch". The glue dries rock hard and is quite strong.

The other method i have used on a part like you have there is to cut a peice of aluminum sheet to cover the back side and pop rivet it from the outside. This looks a bit frankenstein but i don't care it wont crack further. Your part looks like an L shape bent to fit and 4 rivets along the front either side of the crack and 2 on top will do the trick. Take care to make the rivet holes just the right size for the rivets for maximum clamp/hold force.

On the back hidden side roughen the surface larger than the crack with samdpaper. Then get some cyanoacrylate glue from hobby store or "Super Glue" from walmart. put a thin puddle of CA onto the spot then using fingers or sifter sprinkle baking soda onto the glue to coat it evenly. The glue will immediately soak up the BS and heat up. you may hear some crackling and you'll see the glue will look dry. repeat the process making thin layers until you have a large "Patch". The glue dries rock hard and is quite strong.

The other method i have used on a part like you have there is to cut a peice of aluminum sheet to cover the back side and pop rivet it from the outside. This looks a bit frankenstein but i don't care it wont crack further. Your part looks like an L shape bent to fit and 4 rivets along the front either side of the crack and 2 on top will do the trick. Take care to make the rivet holes just the right size for the rivets for maximum clamp/hold force.

I have heard of the baking soda method but not used it. Here's another way I tackle things like that.

Use some epoxy, like JB weld, etc. Mix some up and patch the backside with a flexible insert, like a popsickle stick/tongue depressor. Similar to the 1st response, but quicker with materials usually at hand/already on the shelf. Here's a door sill trim piece I did that way last year; you can't find the crack or know it's patched once re-installed.

Use some epoxy, like JB weld, etc. Mix some up and patch the backside with a flexible insert, like a popsickle stick/tongue depressor. Similar to the 1st response, but quicker with materials usually at hand/already on the shelf. Here's a door sill trim piece I did that way last year; you can't find the crack or know it's patched once re-installed.

The tab on one of the side panels of my 1982 450 Nighthawk cracked and broke off about ten years ago when I was putting it away for the winter. I roughed up the area, supported the tab with sponge ear plugs and smothered it with gorilla glue. It has held all of these years.

My daughters first car had a cracked bumper that swayed as she drove it. I used crazy glue on the edges. The next day I roughed up the area around the crack, layed a wire mesh down and smothered it with gorilla glue . It lasted the six years she had the car.

My daughters first car had a cracked bumper that swayed as she drove it. I used crazy glue on the edges. The next day I roughed up the area around the crack, layed a wire mesh down and smothered it with gorilla glue . It lasted the six years she had the car.

Last edited:

Harbor Freight has a plastic welding kit

HAHAHAHAHA!! I have actually done zip tie stitches. Chick I barely knew came to me with the front bumper all busted up dragging on the ground. It needed to replaced anyway so I went to town on it. Worked mint.

PLASTEX, PLASTIC REPAIR KITS, FIX CRACKS, REPAIR PLASTIC

Manufacturer of plastic repair kits. Plastex easily glues, fills gaps, repairs stripped threads and can remake tabs or small parts in just minutes.

This kit is the best I've seen. Yes, it's a water-thin glue and a product similar to baking soda (I've tried it with baking soda and it does not work the same way, so what ever it is, maybe corn starch, it works well) . However, the glue used is not CA glue. It's a compound I don't recognize.

It will fix "moto" plastics.

It will fix or make "new" barbs for plastic motorcycle side panels. It's that good.

The glue included has a strong and unusual smell. It's not CA glue and it's not PVC glue.

'ya know how PVC glue melts and bonds with pvc, well Plastex glue bonds in the same way with moto plastics.

Last edited:

manicrodder

$50 site donor 2022

JB plastic weld product fixe my pressurized over flow tank's seam on the Frontier. Going strong 4 years later.I have heard of the baking soda method but not used it. Here's another way I tackle things like that.

Use some epoxy, like JB weld, etc. Mix some up and patch the backside with a flexible insert, like a popsickle stick/tongue depressor. Similar to the 1st response, but quicker with materials usually at hand/already on the shelf. Here's a door sill trim piece I did that way last year; you can't find the crack or know it's patched once re-installed.

View attachment 48646

Similar threads

- Replies

- 3

- Views

- 253

- Replies

- 10

- Views

- 3K

- Replies

- 6

- Views

- 1K