Originally Posted By: QuadDriver

if the block pop-off is 15psi, then yes, the small amount of oil flowing thru the filter hot would not open the 25-30psi or so bypass in the filter.

unless he is able to recast the engine block, or do some fancy drilling and welding, he will never measure anything 'across' the oil filter

(to understand this you are going to have to visualize or draw out the oil circuit - keyword - circuit)

btw - the oil bypass in the pump is there to protect not the engine or the pump or the filter. why? how is the pump driven?

I know the oiling circuit on the SBF QUITE well.

There is no block oil bypass on engines other than GM ones that I know of.

Regardless, the CIRCUIT (using your own words) is more restrictive than the filter.

The bypass on the PUMP is there to keep the system at a reasonable maximum pressure (in the case of an SBF, 65psi). Heavy oil and a higher bypass can licorice-stick the oil pump drive shaft in this application.

Gary's measurements were made on a Jeep I-6. This engine has no in-block pressure relief valve, it only has one in the filter, like a Ford or anything not GM. He used a remote filter adapter and put a pressure gauge before and after the filter.

What he observed was that when the relief on the pump opened/closed, that action caused a differential across the filter media that could activate the bypass.

Also, when the oil was cold, the bypass would open. This was observable with a differential between the two oil pressure readings.

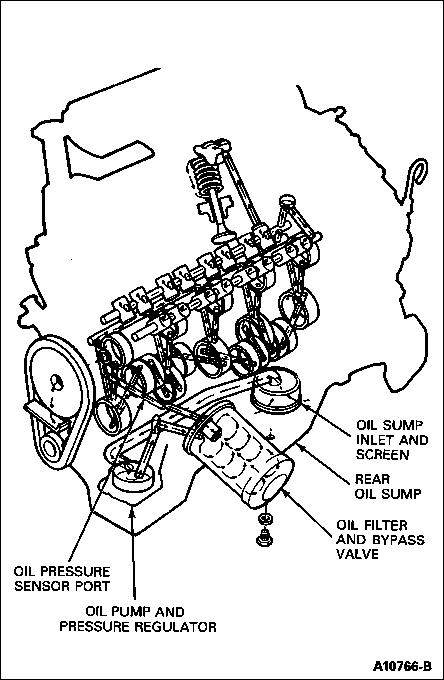

Here is the oiling system on the SBF:

System pressure is regulated AT THE OIL PUMP. This means that any oil going through the engine goes THROUGH the filter. If it can't go through the media, it will go through the bypass ON THE FILTER.

HOWEVER

There is a 12psi differential pressure required to activate the bypass. This isn't total system pressure, this is DIFFERENTIAL pressure, meaning the pressure that the pump sees as back pressure from the system AFTER the filter versus the restriction the filter provides, the DIFFERENCE between those two values is our differential.

When the oil is HOT and can flow easily through the filter, the differential is VERY small (IIRC, Gary stated around 1 or 2 PSI) and NOT enough to open the bypass on the filter. When the oil is COLD and does not flow well through the media, then a large chunk of the oil goes through the bypass.