JHZR2

Staff member

We have a Peerless Purefire modulating/condensing boiler for our hydronic system. It is rated at 95% efficient, so is as efficient as you can reasonably get, and we use it both for our heating and via an indirect water heater (so no duct or draft losses of a typical tank heater). We have been really happy with the system, and it has been trouble free for us. But there is an annual service recommended, and the computer seems to recommend service based upon hours and number of firings.

So I looked into the manual to see the process. Not that much detail, but this is actually a pretty simple system, not much to it. But I photographed my work as a record and to keep track of what I took apart and its condition, so I figured I'd put the photos here for folks interested...

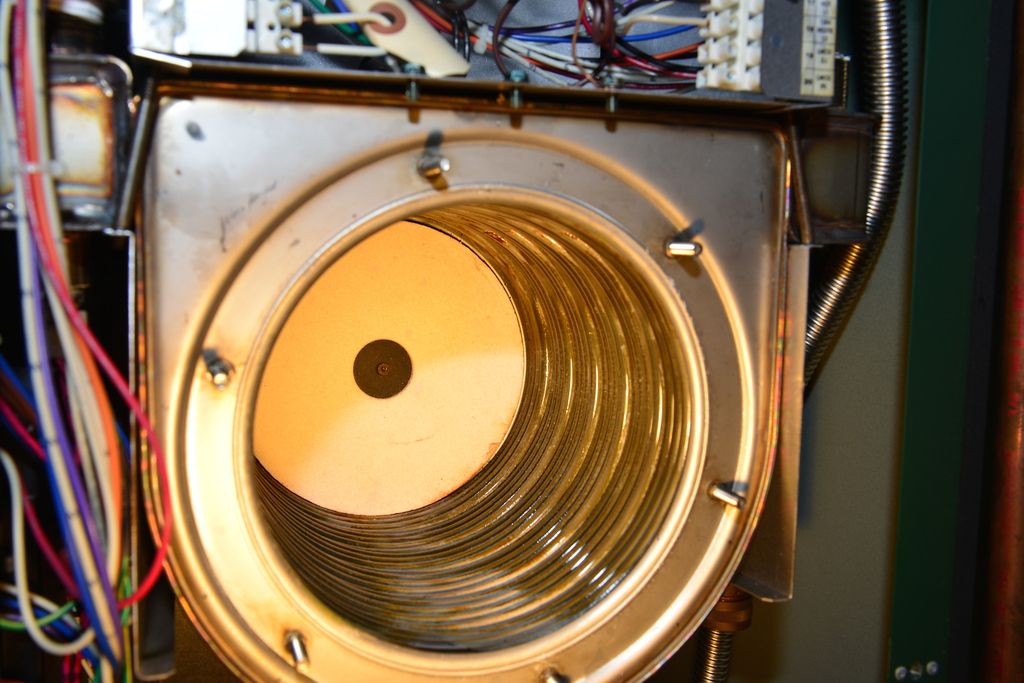

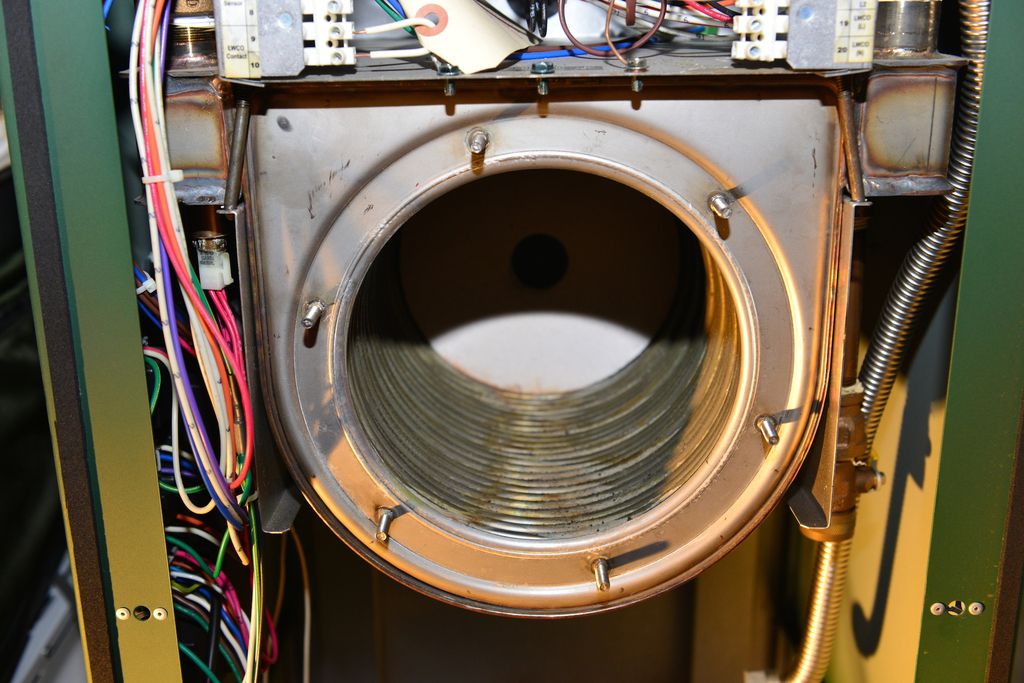

This is the system with the cover off:

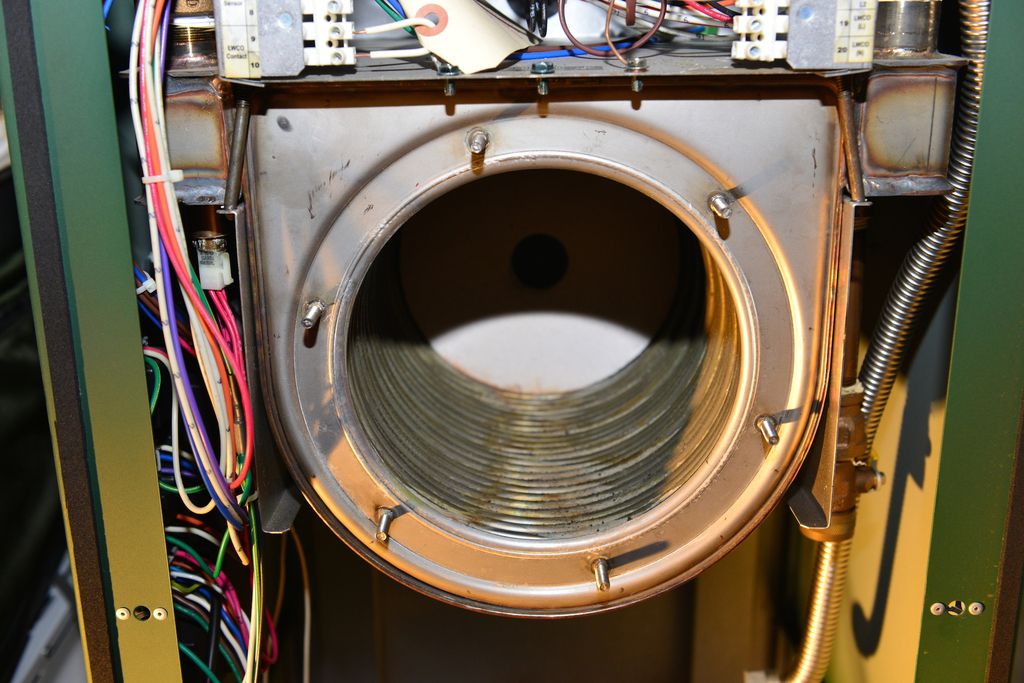

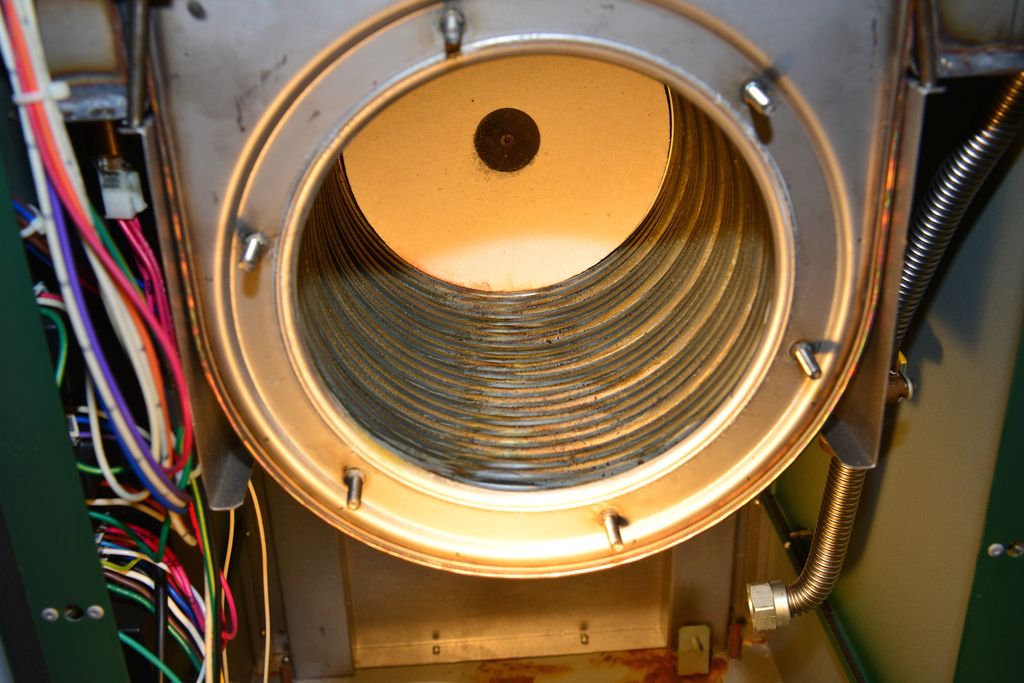

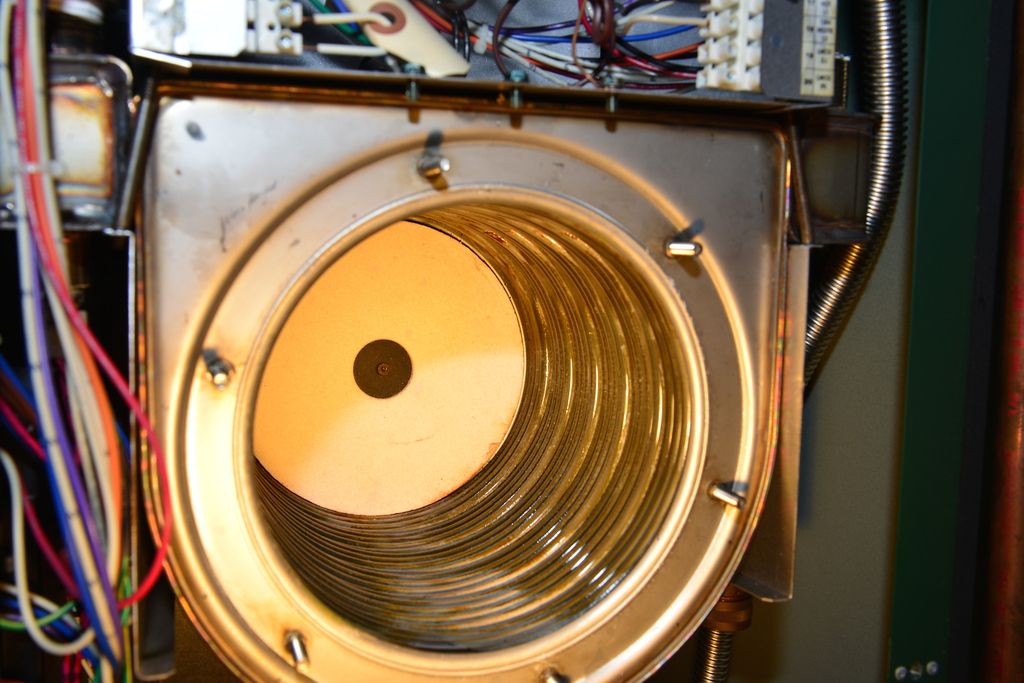

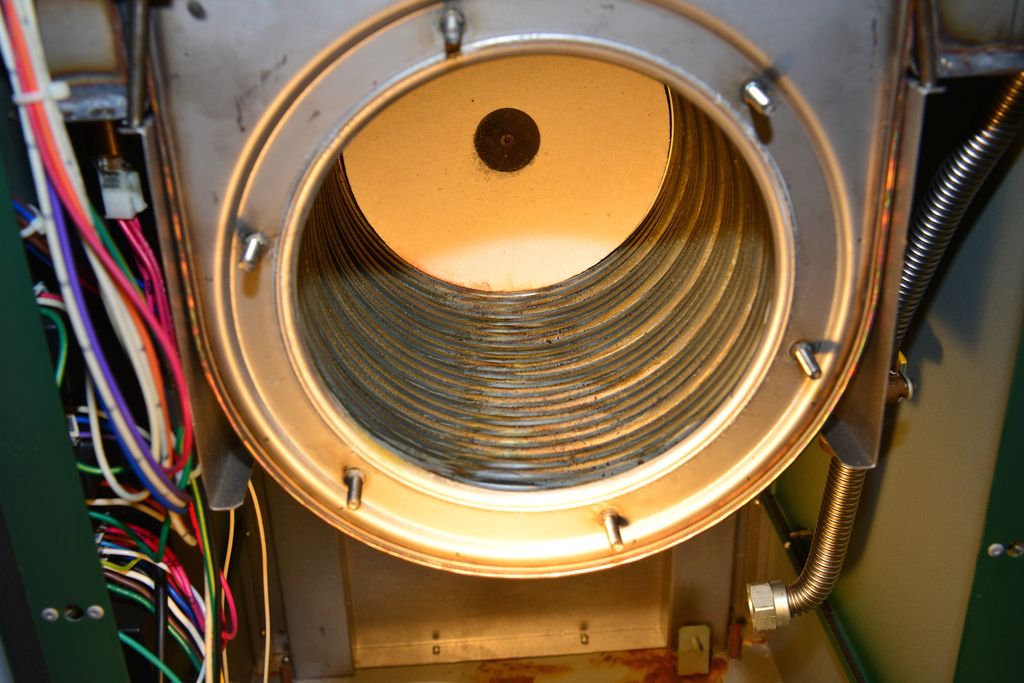

The round thing in the middle is where the coils are located which circulate the heating water and where the system is fired. This is a modulating/condensing boiler, so the front section is the burner, which somehow presents a flame in a radial manner to heat the coils. The gas is modulated to ensure a specific set point and delta T from outgoing to incoming. Because it is all stainless, it is set up to condense, thereby retrieving the heating value of the vaporized water, which is why it is so efficient. The condensate is drained, neutralized, and pumped away.

Here it is with the center burner section removed:

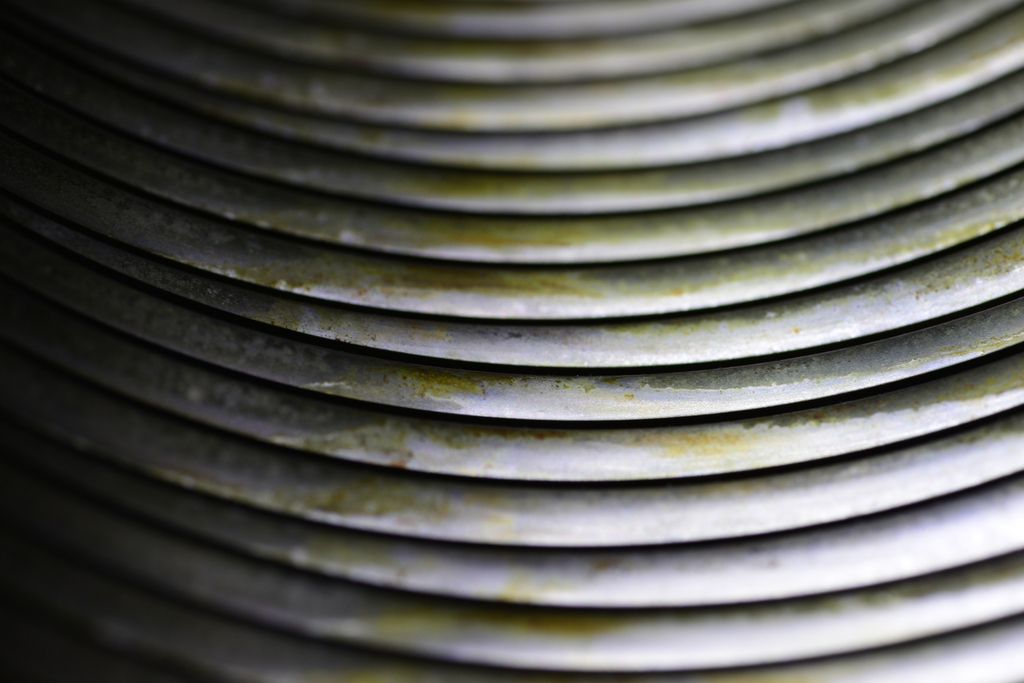

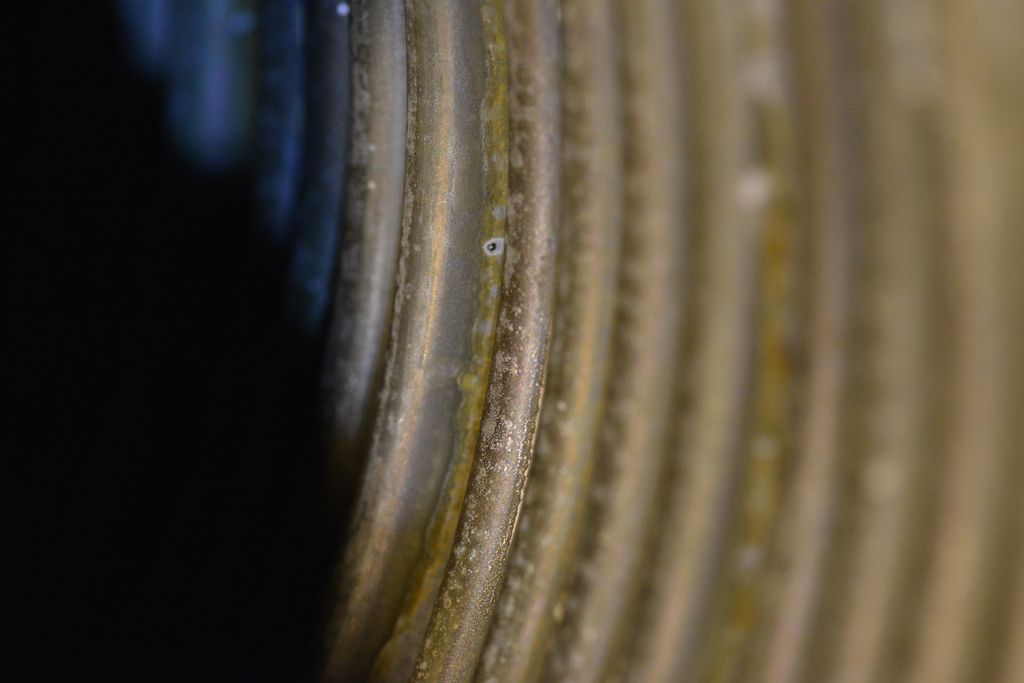

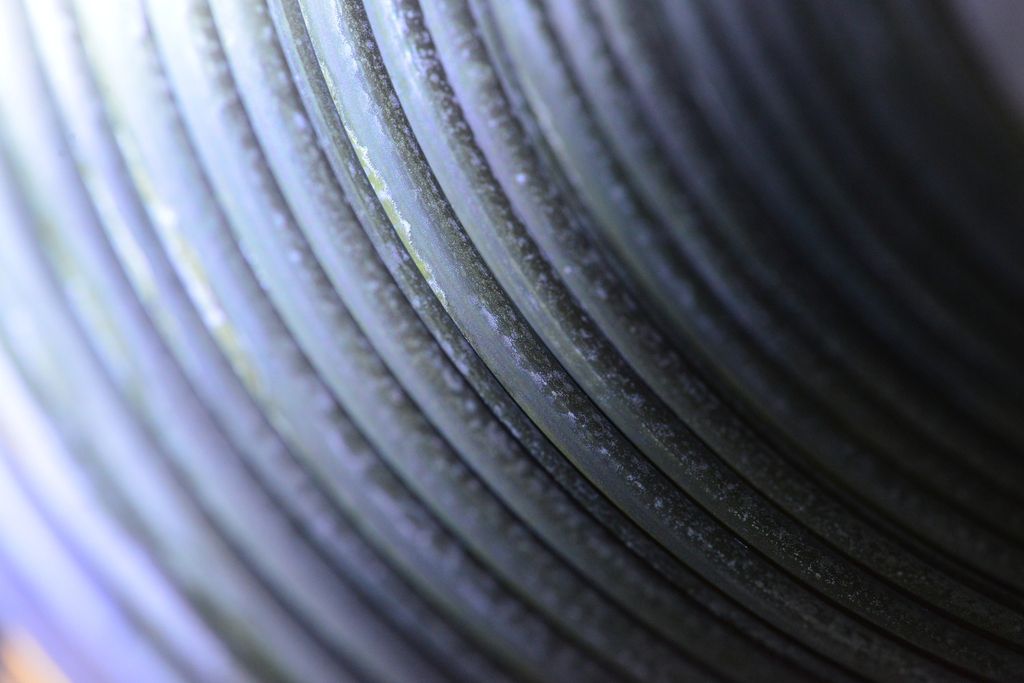

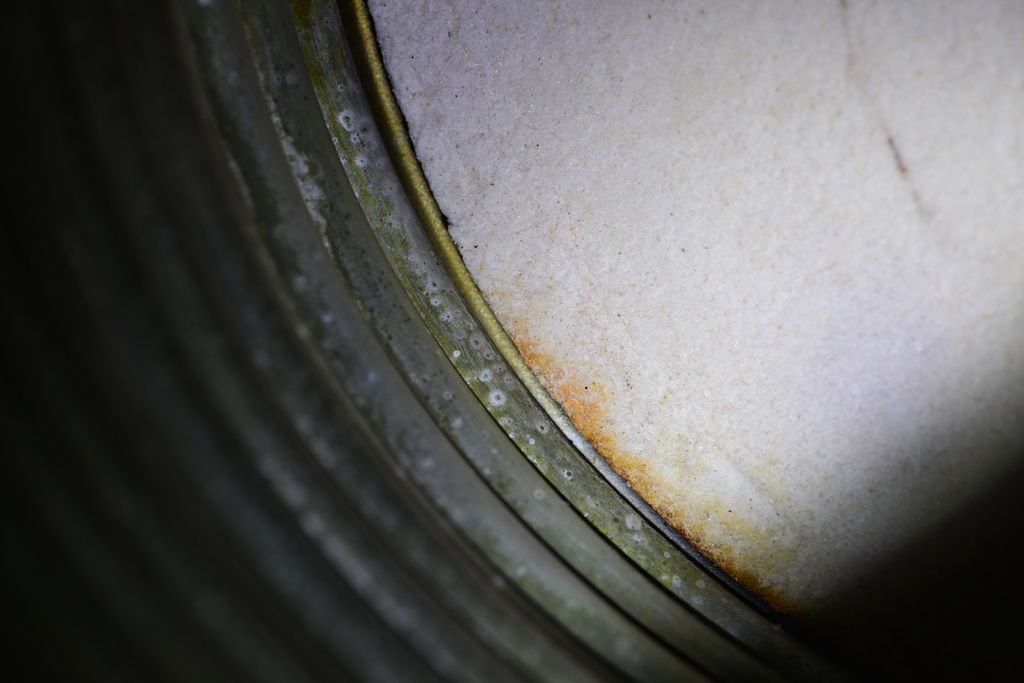

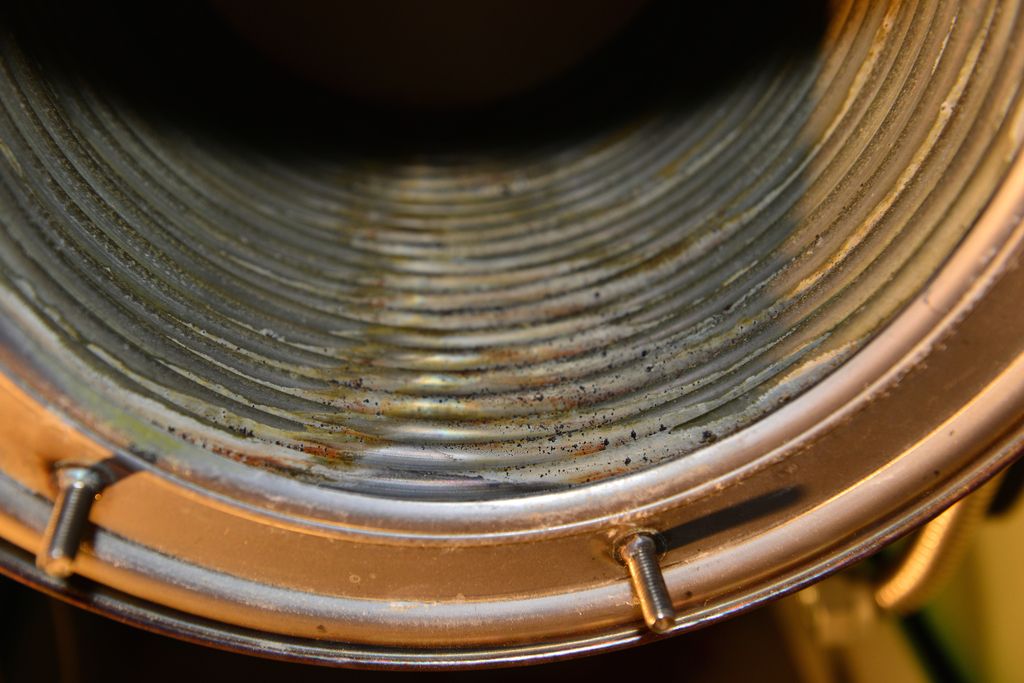

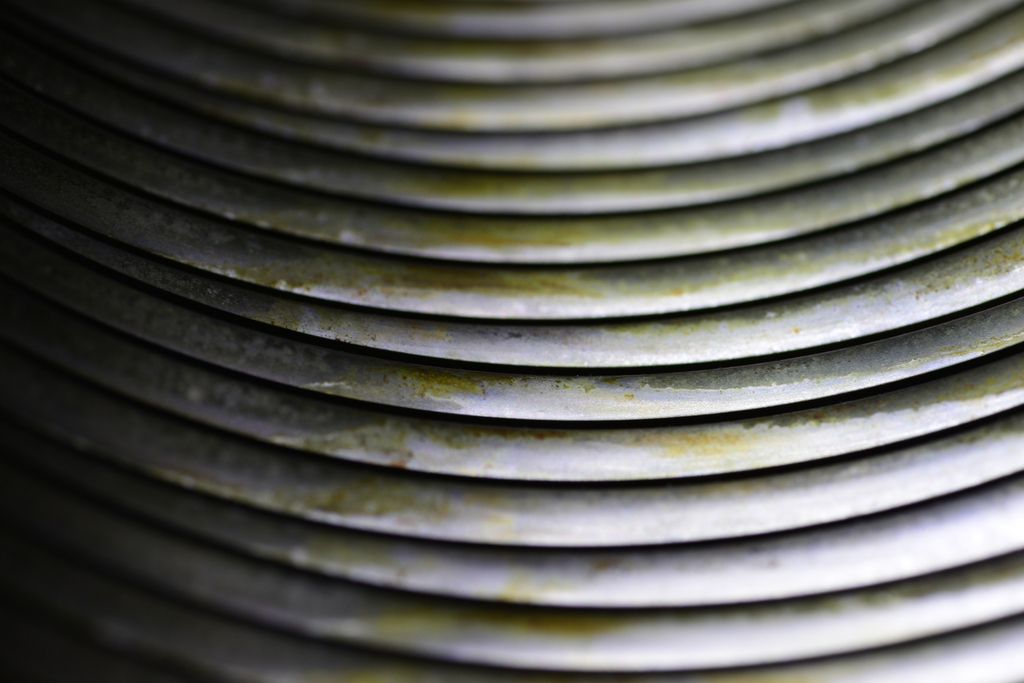

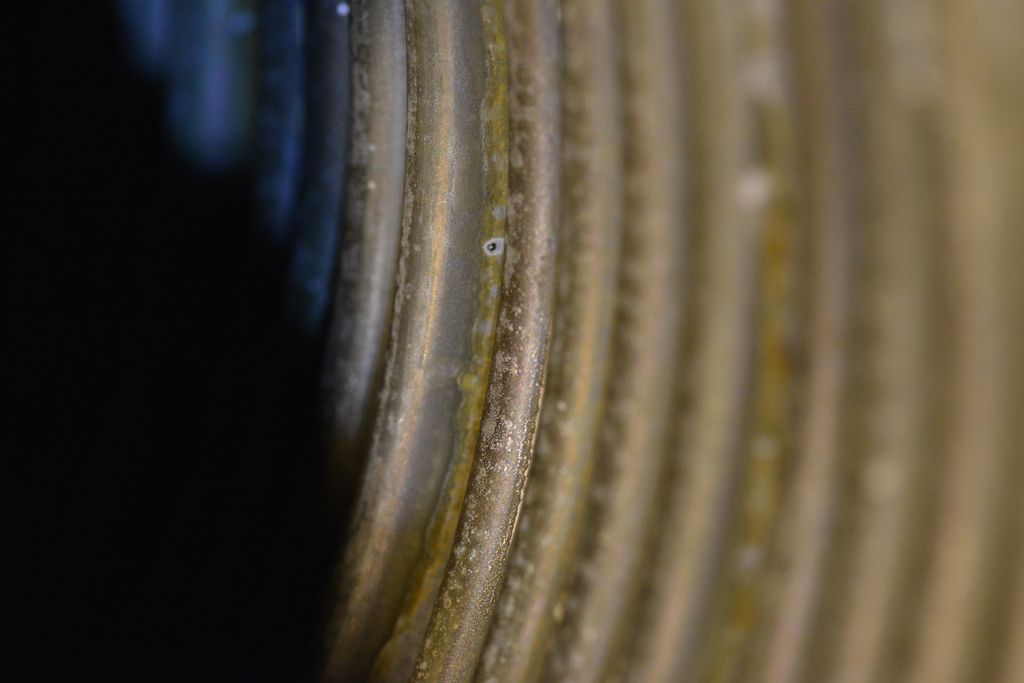

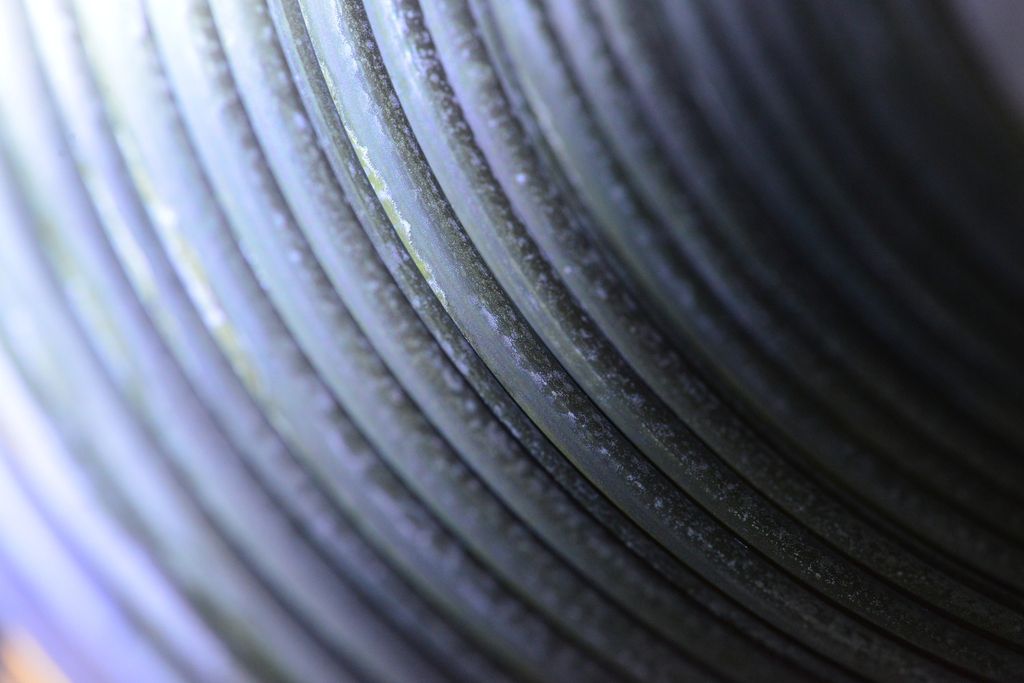

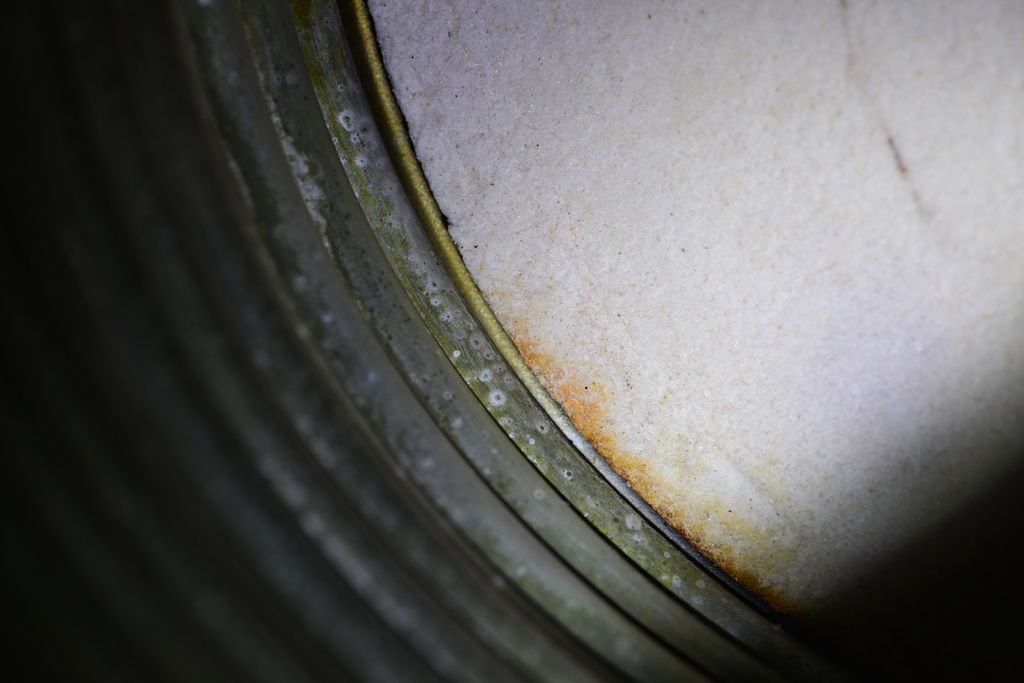

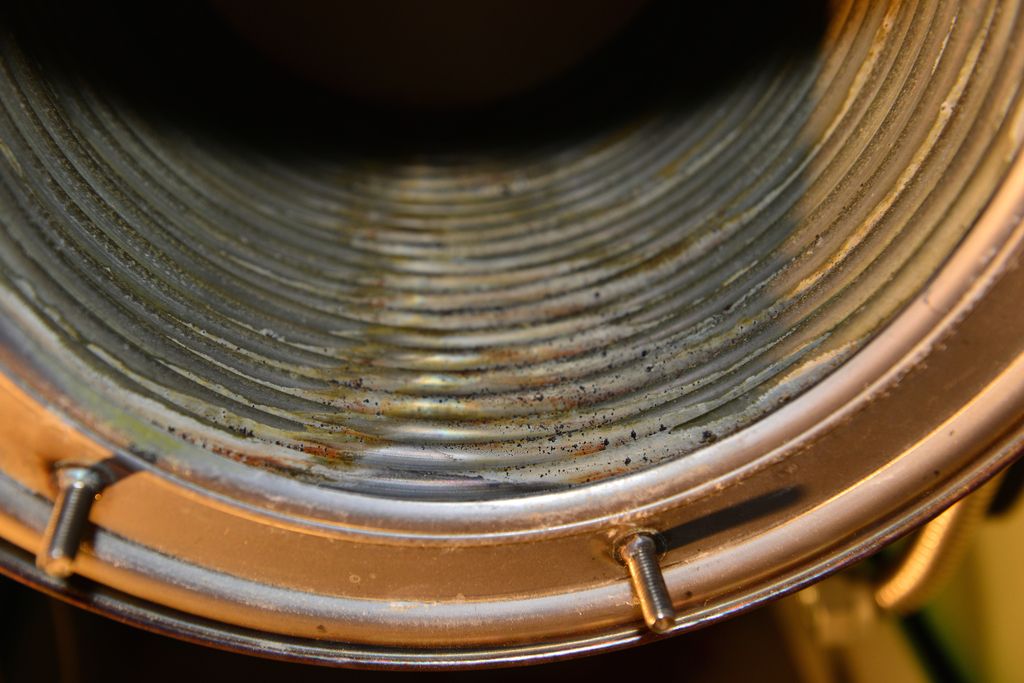

I was sort of surprised to see the amount of rust looking discoloration on the upper section, and the relative lack of dirt and debris on the coils. Yes, there's some, but its not a ton. The tops and bottoms were dirty/discolored/rusted, but the sides were generally pretty clean.

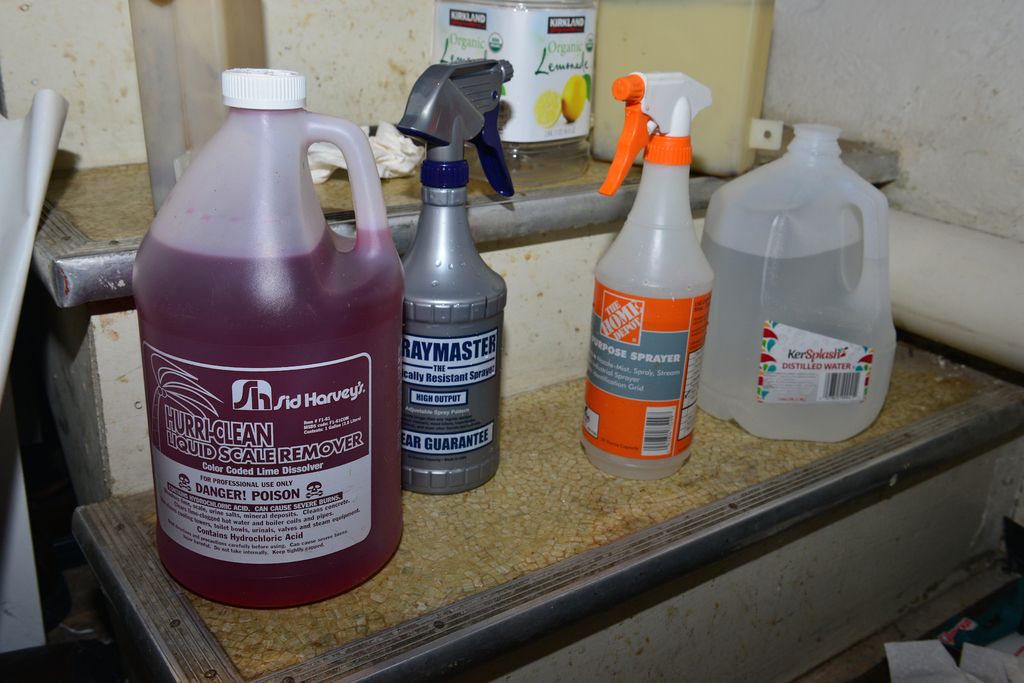

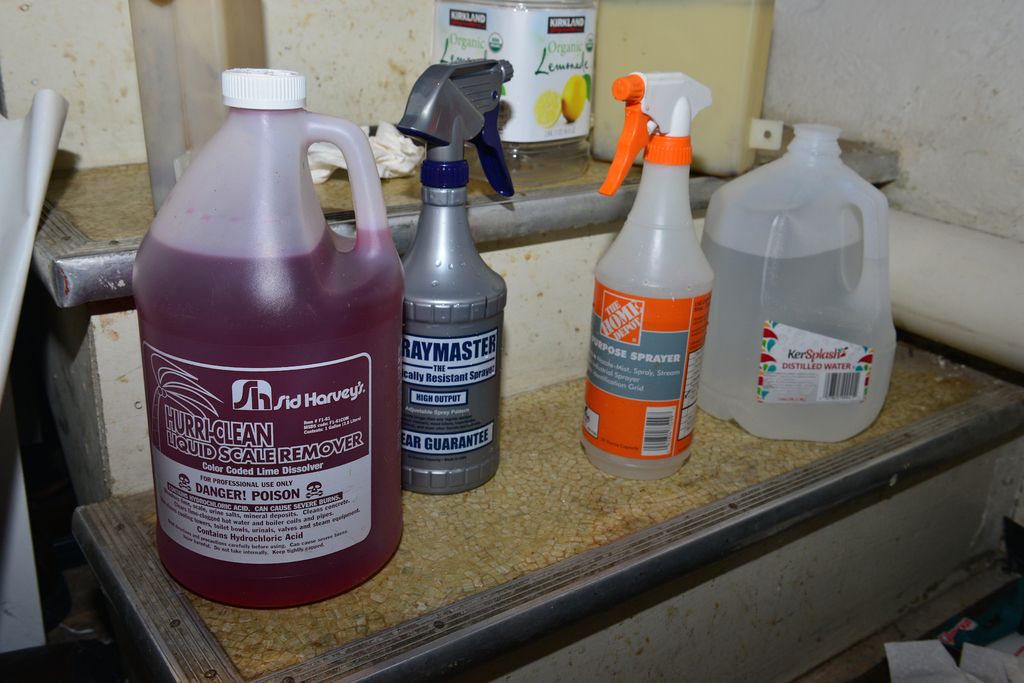

Peerless recommends using a product called Rydlyme, but its very difficult to find anyone who carries it. They also say to use CLR as an alternate. Maybe someday Ill use RydLyme, but the local Sid Harvey distributor carries an HCl product that can be diluted down for this sort of application, for like $14 or so... So I got my stuff together. I used distilled water for the wash down...

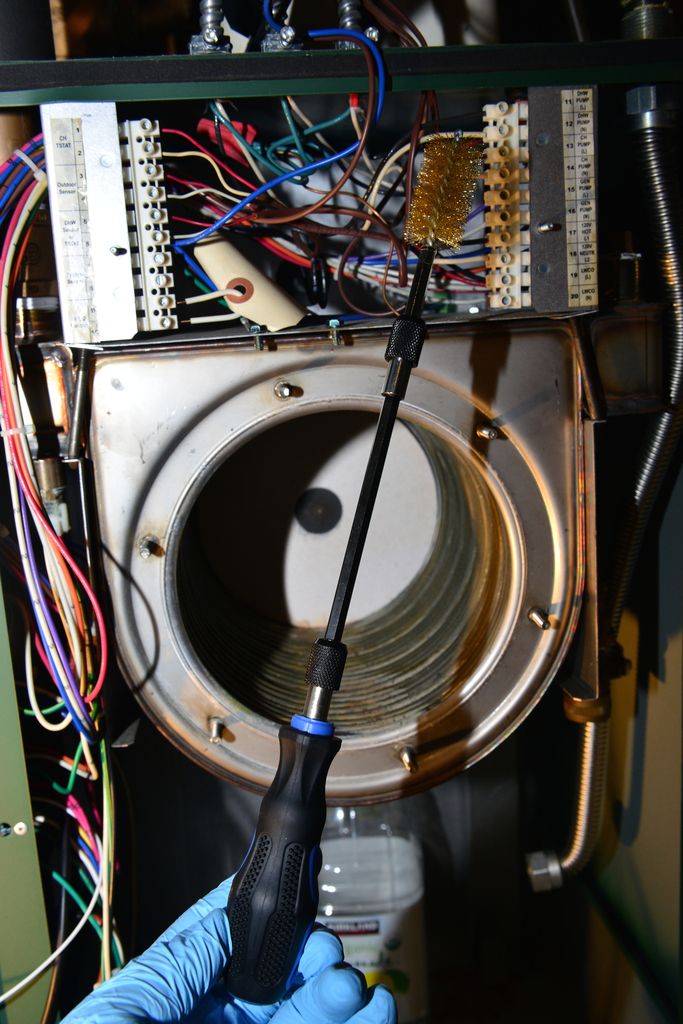

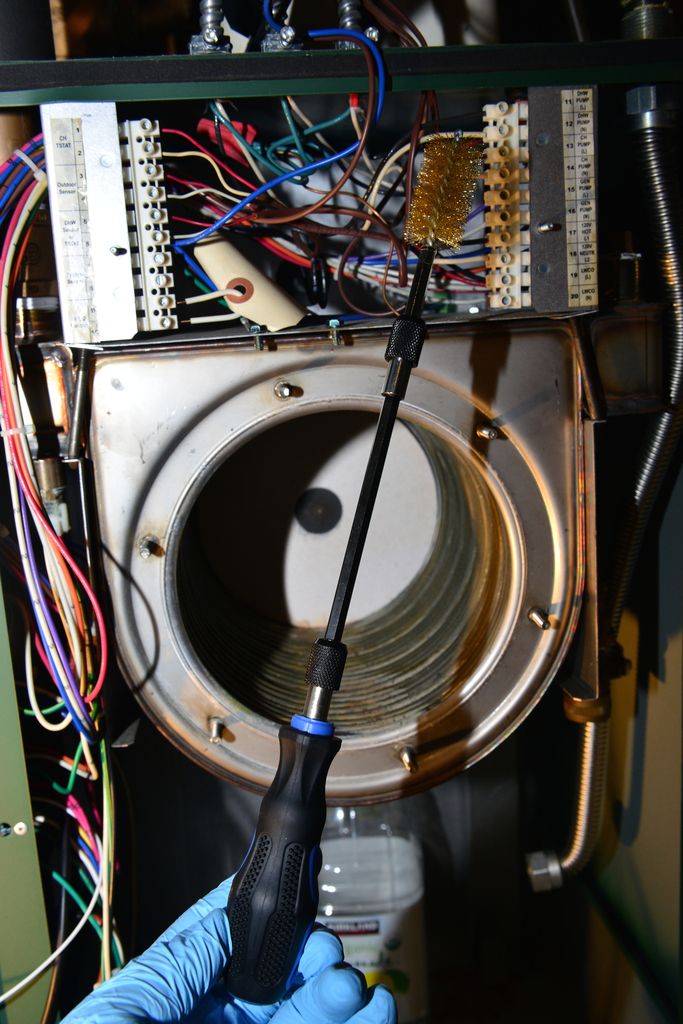

Believe it or not, Harbor Freight had this great nylon and brass scrubbing tool, while all that HD had was some brushes by the welding supplies (that were also made in China). The brass brush from HD also came in handy, but this was really useful for working the coils.

So that's what I did - used the round brush to wipe around the coils continuously, just work my arm in a circular manner and the brush sort of "rode" the coils. The longer bristle welding brush from HD just got a bit deeper and I didn't have as much worry due to it being potted in a wood handle. There was a lot of discoloration that I didn't really get. The descaler product recommended a 1 part descaled to 20 parts water mixture, not sure if I didn't go strong enough... How did I do??

So I looked into the manual to see the process. Not that much detail, but this is actually a pretty simple system, not much to it. But I photographed my work as a record and to keep track of what I took apart and its condition, so I figured I'd put the photos here for folks interested...

This is the system with the cover off:

The round thing in the middle is where the coils are located which circulate the heating water and where the system is fired. This is a modulating/condensing boiler, so the front section is the burner, which somehow presents a flame in a radial manner to heat the coils. The gas is modulated to ensure a specific set point and delta T from outgoing to incoming. Because it is all stainless, it is set up to condense, thereby retrieving the heating value of the vaporized water, which is why it is so efficient. The condensate is drained, neutralized, and pumped away.

Here it is with the center burner section removed:

I was sort of surprised to see the amount of rust looking discoloration on the upper section, and the relative lack of dirt and debris on the coils. Yes, there's some, but its not a ton. The tops and bottoms were dirty/discolored/rusted, but the sides were generally pretty clean.

Peerless recommends using a product called Rydlyme, but its very difficult to find anyone who carries it. They also say to use CLR as an alternate. Maybe someday Ill use RydLyme, but the local Sid Harvey distributor carries an HCl product that can be diluted down for this sort of application, for like $14 or so... So I got my stuff together. I used distilled water for the wash down...

Believe it or not, Harbor Freight had this great nylon and brass scrubbing tool, while all that HD had was some brushes by the welding supplies (that were also made in China). The brass brush from HD also came in handy, but this was really useful for working the coils.

So that's what I did - used the round brush to wipe around the coils continuously, just work my arm in a circular manner and the brush sort of "rode" the coils. The longer bristle welding brush from HD just got a bit deeper and I didn't have as much worry due to it being potted in a wood handle. There was a lot of discoloration that I didn't really get. The descaler product recommended a 1 part descaled to 20 parts water mixture, not sure if I didn't go strong enough... How did I do??