Just as a note, that's the same as drain/refill, when using the same amount of oil. Old fluid will mix with the new one in torque converter, drain pan...Full exchange via cooler line.

This is not toothpaste to be pushed out unmixed.

Just as a note, that's the same as drain/refill, when using the same amount of oil. Old fluid will mix with the new one in torque converter, drain pan...Full exchange via cooler line.

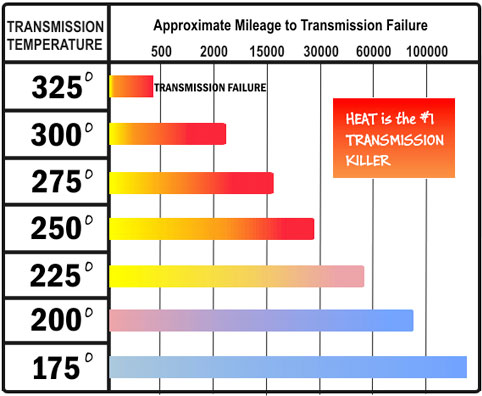

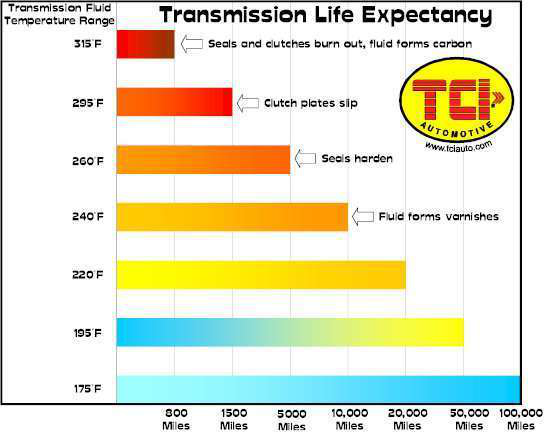

IMO every Toyota used for towing needs to have an auxiliary cooler installed. Their transmission coolers are not adequate for towing.in typical Toyota fashion, my fluid hit 245*F multiple times in fairly cool weather.

Yes, but when you run 14 quarts through, there‘s not much of that original fluid left.Just as a note, that's the same as drain/refill, when using the same amount of oil. Old fluid will mix with the new one in torque converter, drain pan...

This is not toothpaste to be pushed out unmixed.

You can do exactly the same with successive drain/refills (with drives in between) in amount of 14 Qt.Yes, but when you run 14 quarts through, there‘s not much of that original fluid left.

The newer formula LV's and ULV's not only incorporate higher percentages of higher Group fluids, but also have improved and more stable DI and VII components which means higher shear stability, more stable Friction Modifiers, improved Anti-Oxidation, and better Metal Inhibitor and Anti-Wear chemistry....People keep using LV in place of normal viscosity because... I don't know why.

Some prefer to incrementally do drain and refills to slowly clean neglected transmissions, that is, those with high mileage on the fluids.Yes, but when you run 14 quarts through, there‘s not much of that original fluid left.

What comes out at the end is cherry red - looks like new fluid.

Similar to when you change your engine oil, there will be a small amount of the old oil that you can’t get out.

Is it better than doing a ”spill & fill” at more frequent intervals? I don’t know. I guess you’d have to do a controlled test to get the answer to that question. Some guys here prefer that method, especially those who do a lot of towing and hauling. Perhaps on some failure-prone transmissions, doing both might be a good idea.

Personally, I prefer to swap the entire system capacity at less frequent intervals, on my truck, especially since I don’t do heavy towing and hauling (couple of motorcycles or a U-Haul from time to time), and it mostly serves as my commuter on my 36-mile highway round trip commute 4-5 days per week.

And I changed diff fluid at the same time.

Wouldn't be better to start at the SAME viscosity, as specified by manufacturer, and remain in grade? I know that, for example, AMSOIL has a normal viscosity synthetic ATF.The LV and ULV ATF's, while they have a lower starting viscosity, will remain in grade at much higher temperatures.

The Dexron VI series use the improved chemistry, as well as the Amsoil ATF and the fuel efficient LV ATF (ATL), as do the Redline series of fluids.Wouldn't be better to start at the SAME viscosity, as specified by manufacturer, and remain in grade? I know that, for example, AMSOIL has a normal viscosity synthetic ATF.

I prefer to save money in transmissions than on a fractional gas mileage improvement.

Fractional being 21%.fractional decrease in viscosity results in increased internal wear

It seems you have changed the cause-and-effect discussion to a different topic.Fractional being 21%.

So... possible reduced pressure on internal clutches/bands is no biggie? Because we have a strong fluid that protects the metallic gears?

My post was about people using LV in transmissions that were not designed for that.

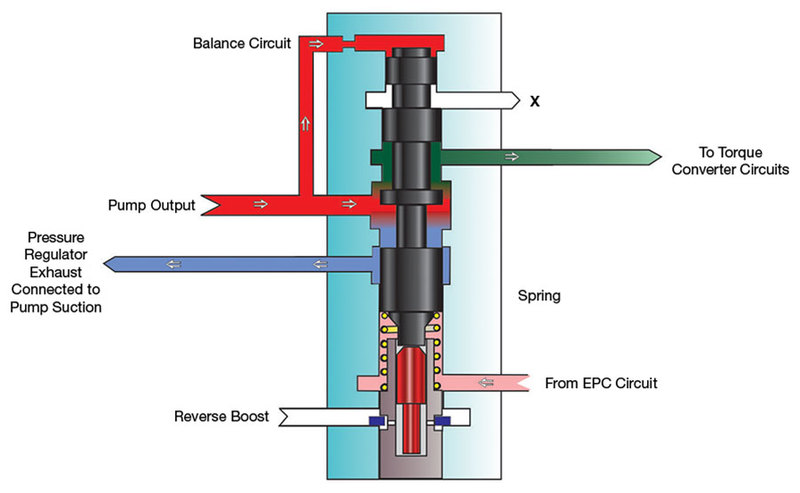

Viscosity is very important in a transmission that works using that viscosity to create pressure differentials inside the valve body.

Who makes that pressure? Let me tell you - the resistance to fluid flow. If there is no resistance, the displacement pump makes zero pressure.at an AT internal pressure of 150 psi

Anyone who has investigated AT hydraulic systems knows it is the pump that creates hydraulic pressure, but that is not the question. The question was/is: If a lower viscosity fluid of the same volume is placed inside the AT, what will be the pressure change within the original transmission in question?Who makes that pressure? Let me tell you - the resistance to fluid flow. If there is no resistance, the displacement pump makes zero pressure.

The same way, an open water hose has no static pressure inside either. Only when flow is restricted (friction pressure drop in a valve) you get some static pressure inside that fluid.

So yes, friction is super important in how a hydraulic circuit maintains the pressure.

It's fluid dynamics 101, some dude, Bernoulli figured it out a while back.

I mean, I never went to that extreme but I once owned a Honda Accord with the old “trouble transmission” and I changed the fluid once a year. It averaged out to be 15,000-25,000 miles, depending on how much I drove that year. You couldn’t drop the pan on those, so they were just simple drain and fills. Never had a problem with that transmission as long as I owned it (289,000 miles). And those cars/transmissions were known to fail between 70,000-120,000 miles. Class action suite. Black eye for Honda.Not saying this is right or wrong, but for as long as I can remember, my Dad has had both a car, and one ton diesel 4x4 to. About every 10,000 to 15,000 kms he drops the transmission pan, new filter, puts the pan back on, and refilled with new ATF. Not sure what percentage of the oil actually drains out, as only some of it does. His theory is that doing it often, will after some time ensure that most of it gets replaced with new fluid, before it gets too old. He has never had a transmission problem, and he works his trucks hard.

Run a pump with an open hose, no restriction. What pressure do you have on that open hose?the pump that creates hydraulic pressure

What's a slippery fluid?Slippery fluid can create a lower pressure on those regulators.

Also internal orifices (valve body) are calibrated for fluid viscosity, not for static pressure.

In extremis, imagine you run water or air at 150 psi trough that transmission. Will it work? What's different? Viscosity!

Those charts are obsolete because they assume first generation-type Dex/Merc fluids and do not consider fluids with the later, enhanced additive and base oil chemistry.I suspect those charts may be old data. The trans in my truck is regulated to 205F nominal, with a life expectancy of under 50k per the chart. Thats either alarmist or old data. Ive had a couple of town and countries with an instrumented trans.... those guys start at 160F and spent plenty of time 180-220F, and alarmingly more on a hot hill climb with the AC on... 240+.... those were undercooled! They were not considered robust units, but both my vans were high miles, one did some towing, and they certainly made it farther than the chart suggests. My tundra (2006) towed heavy all day long between 160-180F, again, with a 3rd party gauge on the cooler line. With the AC off on a daily basis it might reach 130, never went over 160. I know the new ones run warmer by design...