But likewise Edison did not invent nor use tungsten filaments since the element was too difficult to work with.

My reading is that Thomas Edison anticipated that tungsten would be the ideal material for light bulb filaments if they could ever figure out how to work with the material. GE was the first manufacturer of mass-produced tungsten filament light bulbs.

Learn the story of inventor Thomas Edison, and his workshop's journey to the invention of the incandescent lightbulb in 1879.

www.fi.edu

By January 1879, at his laboratory in Menlo Park, New Jersey, Edison had built his first high resistance, incandescent electric light. It worked by passing electricity through a thin platinum filament in the glass vacuum bulb, which delayed the filament from melting. Still, the lamp only burned for a few short hours. In order to improve the bulb, Edison needed all the persistence he had learned years before in his basement laboratory. He tested thousands and thousands of other materials to use for the filament. He even thought about using tungsten, which is the metal used for light bulb filaments now, but he couldn't work with it given the tools available at that time.

But GE hired someone who figured out how to work with tungsten at a mass production scale. The first ones sold were interesting too as they used a mercury amalgam (like dental fillings) where the softer metals were then melted out. I guess it worked, but it was spongy and brittle.

One hundred years ago, William D. Coolidge coaxed tungsten into filaments, illuminating incandescent light bulbs—and the world.

www.americanscientist.org

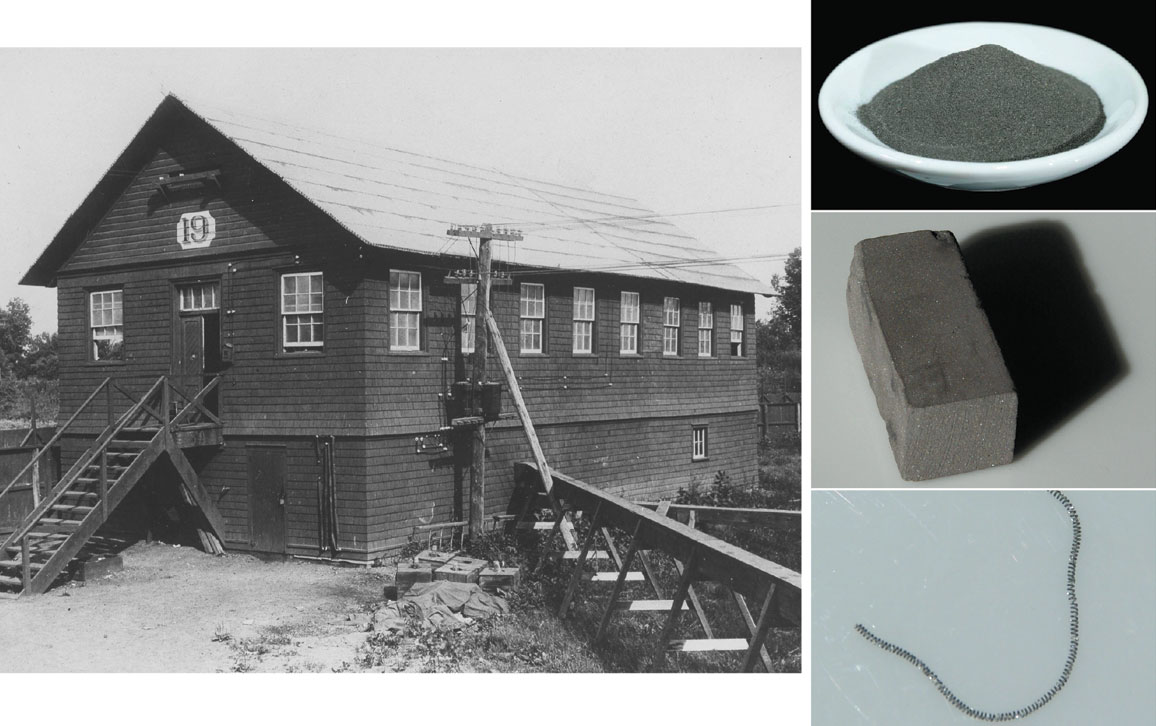

In March 1906, a breakthrough happened when a spongy rod of tungsten accidentally fell into a pool of liquid mercury from the sintering furnace, and the mercury filled the pores. Coolidge then recalled getting a tooth filled as a child. His dentist had prepared the amalgam by combining silver slivers, shaved off of a Mexican coin, into liquid mercury; the young Coolidge noticed that this sticky paste was moldable before it stiffened into a permanent shape. Coolidge realized that mercury could be mixed with tungsten and then squirted into wire. He mixed tungsten into an amalgam made of mercury and other soft metals, including bismuth and cadmium, extruded it, and melted off the amalgam’s softer metals to create a tungsten filament. The filament glowed stably inside a light bulb.

Delighted about the success of his process, Coolidge wrote to his parents in early 1907, “The outlook for my method is certainly very bright now.” GE put the tungsten filaments on the market and soon sold nearly 500,000 of the new bulbs. Coolidge’s mother wrote that fall, “Your lamps are already in town.” But the tungsten filaments were still fragile: The amalgam gave filaments their flexibility, yet after the soft metals melted away, the remaining brittle tungsten particles could easily snap. So Coolidge was tasked with making a more robust version that could withstand harsher conditions such as vibrations in cars and trains.

*****

Coolidge’s contributions have been largely forgotten compared with Edison’s, in part because the shy and introverted engineer preferred to quietly unlock puzzles and remain out of the spotlight. But Coolidge had tenaciously tamed tungsten, and in a 1922 newspaper article even Edison admired his ability to wrangle “so rebellious a metal.”

And the building where they developed these technologies doesn't seem to be terribly high tech: