That’s my favorite road!View attachment 119054

Thanks for the warm welcome, @john_pifer! Here is a photo from when I visited Tail of the Dragon on August 30th. The camera setup you see is for a passion project where I record scenic roads. I installed riv-nuts in the hood for a hard mount so I don't need to worry about it ever coming loose (or losing suction). RibbonWork was going to be the name of my YouTube channel before I decided on something else. I am the fourth owner of this car, third in its (mostly) current form after it received a 6MT swap and other upgrades. This car has had two other owners on the LegacyGT.com forums where you can find its build thread. This car is my project car and one that I hope to hold on to indefinitely. I bought it in Humboldt County, CA and drove it back East - that profile picture of mine was taken in Monument Valley. I learned most of my shadetree skills, replaced my first timing belt, clutch, and fuel tank on it.

@Vermess, here's my UOA thread showing that I likely have bearing failure and blown head gaskets. In addition to taking this car filming on road trips, I also track it and would like to get into autocross. I've been speaking to a few reputable builders in the Northeast and exploring my short block replacement options.

The added benefit of a coolant pre-heater is that it also provides heat to the interior of the cabin. When I'm on my filming trips I sometimes decide to sleep in the wagon and it can get quite cold in the winter. @SubLGT , the most involved aspect of the pre-heater is installing a standpipe into the fuel tank. Do you have an LGT too? Ideally, we can install the standpipe through the fuel pump access doors. Dropping the rear subframe in order to drop the tank is not fun.

I know this pre-heater idea is overkill for most people, I come from a long line of males who come up with harebrained ideas so it's a congenital condition. Interestingly, when I browse European eBay I see that these units come from the factory for economy cars like the VW Golf. In either case, this is just an idea that interests me.

From what I read, it seems like most 2618 owners report 50-75k from their engines before they need to be refreshed for excessive compression loss. 4032 experiences are harder to find, but Rallispec told me that they used to be used in OEMs until emission standards became more stringent. @UncleDave, how is a marine engine's lifetime measured?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Improving Forged Engine Longevity w. Coolant Pre-heaters (i.e. Webasto, Eberspächer)

- Thread starter Enlight

- Start date

Neat car! My wife had a 2005 Legacy GT wagon with 5 speed manual for 14 years since brand new.

Enlight

Thread starter

I've been reading up on thermostats as well and it seems like the 160f unit I have is not ideal. An 8k rpm limit would be very nice. It's possible an over-rev during downshift on a track day contributed to my engine failure. For whatever reason, the engine builders I've reached out to are happy to write back long emails describing their recommendations but go quiet as soon as I ask for a quote. I'll chalk it up to them being busy.

- Joined

- Aug 12, 2020

- Messages

- 167

As detailed in another UOA I posted, it looks like I will be looking for a new shortblock for my turbocharged '05 Subaru Legacy GT soon. I began by only considering OEM replacement options because I wanted a long-lasting engine; that is before I discovered engine coolant pre-heaters. While I'm aware of freeze plug and oil pan heaters, I'm primarily interested in getting the entire engine's internals closer to operating dimensions before the engine ever turns over. My understanding is that the primary reason forged engines suffer shorter lives is because of thermally contracted pistons at startup. Following that logic, solutions that actively circulate coolant throughout the entire block will pre-heat the internals more evenly. Both the Webasto and Eberspächer will heat coolant up to 80°C or 176°F.

All other factors being equal, are there any reasons why an engine with forged internals would not last as long as one with cast internals with a coolant pre-heat system?

According to this neat chart I've found from Engine Builder Magazine, raising temps to 176°F get 4032 and 2618 pistons less than halfway to their final (approx. 572°F) operating dimensions.

Before I say anything else in regards to Subaru engines and built ones, let me recommend Mahle powerpak strut type pistons for your application. 2618 alloy, very much tougher than oem.

Most Subaru engines don't last with forged internals because people don't know how -- or they do not have the equipment -- to rebuild them properly.

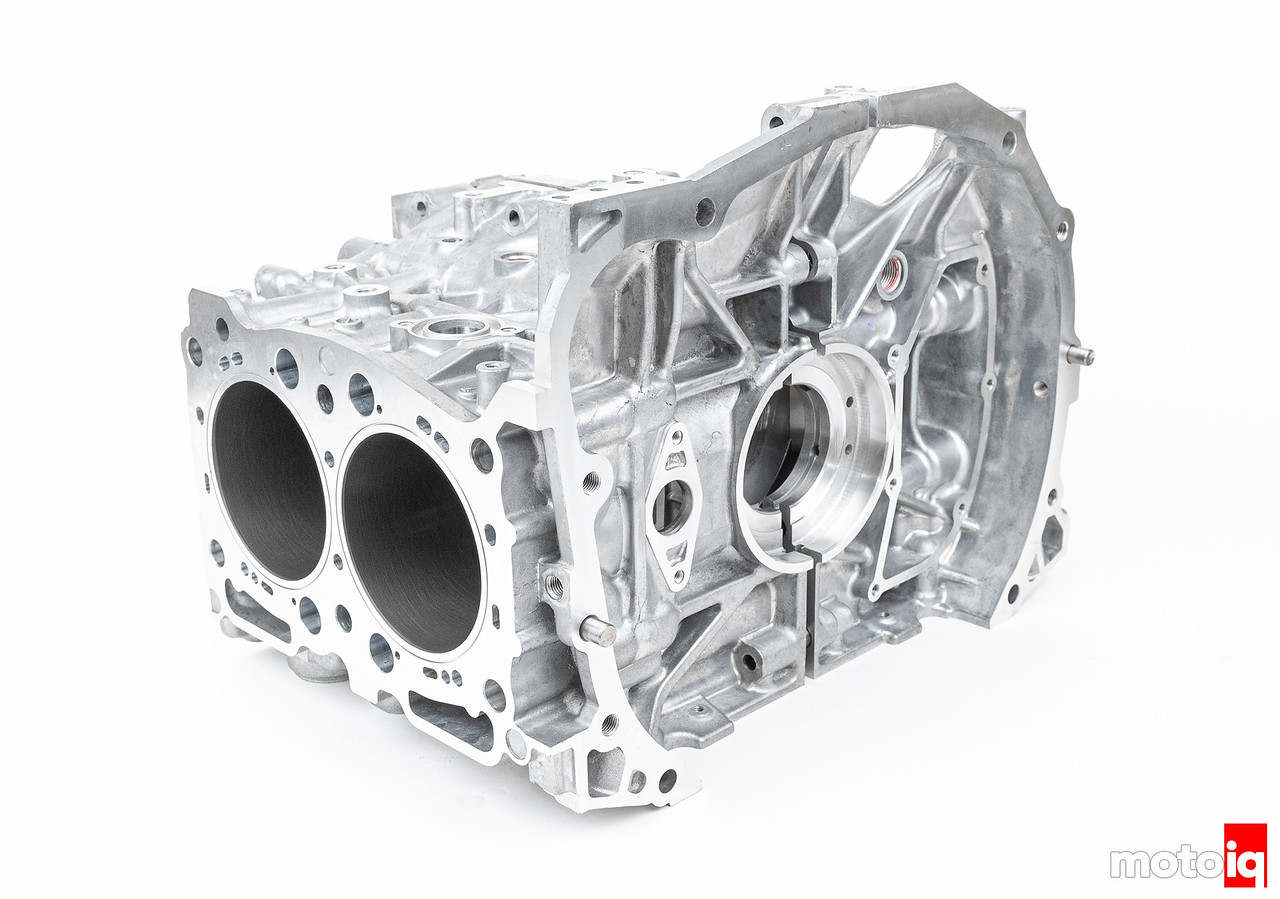

EJ25 cases aren't very stiff. They flex a LOT when you torque them together and when you put the heads on. This means that you need to have the ability to machine the cases when they're bolted together and have torque plates on them or you're not going to get it right. One of the ONLY companies who can do it right is IAG. MotoIQ has a very good series where they explain the intricacies of machining and building an EJ with forged internals for a performance application.

Project GD Subaru STI, Building the Engine Part One, Prepping the Case With IAG Performance. - MotoIQ

It had to happen eventually. Our Project STI was running great. We had plans to build the engine as our 400 whp was past the limit that a stock bottom…

motoiq.com

motoiq.com

Why? Makes no sense to replace the engine on a 17 year old Subaru unless this is a pristine low mileage example. But then, why would it need an engine?

Because they're kinda pieces of ****e that can't stand to be driven by anyone but grandmothers and scared people who rarely accelerate above half throttle or take turns faster than the yellow sign says?

I never had a longevity problem with a forged engine without preheating.

We use them all the time in boating where the duty cycles and loads mangle cast pieces.

Yep, Forged engines can be very reliable.

It's not so much that they're tight, they just have terrible tolerances from the factory (rod bearing clearance can vary significantly from rod to rod), and once you split them open they never go back to what they were.Boxer and flat engines are a different animal compared to v or inline engines(I'm assuming it's what you use in the marine application).

Boxer/flat engines use dumb tight ptw clearances.

View attachment 119054

Thanks for the warm welcome, @john_pifer! Here is a photo from when I visited Tail of the Dragon on August 30th. The camera setup you see is for a passion project where I record scenic roads. I installed riv-nuts in the hood for a hard mount so I don't need to worry about it ever coming loose (or losing suction). RibbonWork was going to be the name of my YouTube channel before I decided on something else. I am the fourth owner of this car, third in its (mostly) current form after it received a 6MT swap and other upgrades. This car has had two other owners on the LegacyGT.com forums where you can find its build thread. This car is my project car and one that I hope to hold on to indefinitely. I bought it in Humboldt County, CA and drove it back East - that profile picture of mine was taken in Monument Valley. I learned most of my shadetree skills, replaced my first timing belt, clutch, and fuel tank on it.

@Vermess, here's my UOA thread showing that I likely have bearing failure and blown head gaskets. In addition to taking this car filming on road trips, I also track it and would like to get into autocross. I've been speaking to a few reputable builders in the Northeast and exploring my short block replacement options.

The added benefit of a coolant pre-heater is that it also provides heat to the interior of the cabin. When I'm on my filming trips I sometimes decide to sleep in the wagon and it can get quite cold in the winter. @SubLGT , the most involved aspect of the pre-heater is installing a standpipe into the fuel tank. Do you have an LGT too? Ideally, we can install the standpipe through the fuel pump access doors. Dropping the rear subframe in order to drop the tank is not fun.

I know this pre-heater idea is overkill for most people, I come from a long line of males who come up with harebrained ideas so it's a congenital condition. Interestingly, when I browse European eBay I see that these units come from the factory for economy cars like the VW Golf. In either case, this is just an idea that interests me.

From what I read, it seems like most 2618 owners report 50-75k from their engines before they need to be refreshed for excessive compression loss. 4032 experiences are harder to find, but Rallispec told me that they used to be used in OEMs until emission standards became more stringent. @UncleDave, how is a marine engine's lifetime measured?

Pre-heater sounds kinda cool for your application. I've taken some trips where I've slept in my car too, and it's always a PITA waking up freezing and firing the car up for a while to get warm again!

I'd ditch the low temp thermostat. Subaru's don't really have cooling issues and they don't like to be cold.

Other than that, your parts list looks like you've addressed most of the EJ shortcomings. One thing I'd suggest is something to control oil consumption via the overly complex and not-very-good Subaru PCV system. There's a couple properly configured kits on the market.

I think you have two options at this point: either buying a new OEM shortblock and feeding it a good 0w40, making sure your tune is spot on and hoping for the best, or having an engine built by a proper machine shop and you'll be just fine.

The shop I worked at for a while build many a forged 500-1000whp 4g63, and we had some customers drive them 30,000-40,000 miles before they'd come back for a new clutch and we'd send them back on their way. From what I know many are still running around the streets. Proper oiling and letting the car get to temp before you beat the daylights out of it is key.

We also built several 500+whp Subaru EJ25's, but the cost was too much for a lot of people and we refused to build them the cheap and improper way (which plenty of people are willing to do), so I have less records when it comes to their longevity. I do know a couple guys that have 30,000+ miles on their forged engines and they have no signs of excess wear.

@Enlight it's not just the higher revs of the ej20y/x, that exhaust cam avcs makes a huge difference especially when tracking.

If you are going to go for the cost effective way, pick up a r/a short block directly from Subaru. Sub 2k, swap everything from your other block onto it.

Also, don't forget to take the plug out of the back of the driver's side head and recirculate that to the heater return. And 180-190 degree thermostat.

@PoorMans180SX oh, you are so right on machine shops not knowing what to do with these engines. 500whp is easy for a ej20x/y. Been there, done that on complete stock long blocks. 1000whp??? I wouldn't think of it without a sleeved block.

If you are going to go for the cost effective way, pick up a r/a short block directly from Subaru. Sub 2k, swap everything from your other block onto it.

Also, don't forget to take the plug out of the back of the driver's side head and recirculate that to the heater return. And 180-190 degree thermostat.

@PoorMans180SX oh, you are so right on machine shops not knowing what to do with these engines. 500whp is easy for a ej20x/y. Been there, done that on complete stock long blocks. 1000whp??? I wouldn't think of it without a sleeved block.

This business might have answers re space heater,

www.rayoutfitted.com

www.rayoutfitted.com

Off Grid Heaters — Ray Outfitted

Canadian Mobile Installer, home base in Ontario. ESPAR, Webasto, Propex, Cubic Mini... Select the best campervan RV or boat bunk heater for you.

Enlight

Thread starter

I've spoken to Prime Motoring, EFI Logics, and RalliSpec now, all reputable tuner-builders. They're all quite busy; I thought they were giving me the cold shoulder but their schedules are just filled months in advance. For my power goals and use case, 2 out 3 have recommended Type RA blocks (with the accompanying supporting mods). My current power levels are sufficient and, as I told the tuners, I don't think I'll ever the feel the need to go beyond 350whp.

@Vermess @PoorMans180SX All tuners agree on the OEM thermostat as you both mentioned. I'm the third owner of this car in its current form and that's one of the items I didn't research when I took ownership.

MotoIQ puts out really great videos. That's really interesting about the torque plates but it makes sense. Flatirons Tuning also puts out good stuff. I'm going to ask about torque plates and whether that is necessary with a Type RA build.

@Vermess @PoorMans180SX All tuners agree on the OEM thermostat as you both mentioned. I'm the third owner of this car in its current form and that's one of the items I didn't research when I took ownership.

Most Subaru engines don't last with forged internals because people don't know how -- or they do not have the equipment -- to rebuild them properly.

EJ25 cases aren't very stiff. They flex a LOT when you torque them together and when you put the heads on. This means that you need to have the ability to machine the cases when they're bolted together and have torque plates on them or you're not going to get it right. One of the ONLY companies who can do it right is IAG. MotoIQ has a very good series where they explain the intricacies of machining and building an EJ with forged internals for a performance application.

MotoIQ puts out really great videos. That's really interesting about the torque plates but it makes sense. Flatirons Tuning also puts out good stuff. I'm going to ask about torque plates and whether that is necessary with a Type RA build.

Last edited:

My current power levels are sufficient and, as I told the tuners, I don't think I'll ever the feel the need to go beyond 350whp.

I'll give it another year before

@Enlight it's not just the higher revs of the ej20y/x, that exhaust cam avcs makes a huge difference especially when tracking.

If you are going to go for the cost effective way, pick up a r/a short block directly from Subaru. Sub 2k, swap everything from your other block onto it.

Also, don't forget to take the plug out of the back of the driver's side head and recirculate that to the heater return. And 180-190 degree thermostat.

@PoorMans180SX oh, you are so right on machine shops not knowing what to do with these engines. 500whp is easy for a ej20x/y. Been there, done that on complete stock long blocks. 1000whp??? I wouldn't think of it without a sleeved block.

What octane fuel gets you to 500WHP?

preheaters makes sense in freezing areas, because engines inject richer when cold. --> effect is worse in direct injection; degreasing cylinders & increase fuel in oil.As detailed in another UOA I posted, it looks like I will be looking for a new shortblock for my turbocharged '05 Subaru Legacy GT soon. I began by only considering OEM replacement options because I wanted a long-lasting engine; that is before I discovered engine coolant pre-heaters. While I'm aware of freeze plug and oil pan heaters, I'm primarily interested in getting the entire engine's internals closer to operating dimensions before the engine ever turns over. My understanding is that the primary reason forged engines suffer shorter lives is because of thermally contracted pistons at startup. Following that logic, solutions that actively circulate coolant throughout the entire block will pre-heat the internals more evenly. Both the Webasto and Eberspächer will heat coolant up to 80°C or 176°F.

All other factors being equal, are there any reasons why an engine with forged internals would not last as long as one with cast internals with a coolant pre-heat system?

According to this neat chart I've found from Engine Builder Magazine, raising temps to 176°F get 4032 and 2618 pistons less than halfway to their final (approx. 572°F) operating dimensions.

and this is never good.

E85 and 93 mix. Ethanol sensor gotta read 40 percent meth content to.Lower than 40, you'd ping, higher than 55-60 the hp gain was negligible. I'd aim for 50. Tbh, I think I was running out of turbo on my setup.What octane fuel gets you to 500WHP?

I think you're getting something mixed up. The RA block comes pre assembled as a short block. All machine work done. Torque plates not needed. Just bolt your stuff on.I've spoken to Prime Motoring, EFI Logics, and RalliSpec now, all reputable tuner-builders. They're all quite busy; I thought they were giving me the cold shoulder but their schedules are just filled months in advance. For my power goals and use case, 2 out 3 have recommended Type RA blocks (with the accompanying supporting mods). My current power levels are sufficient and, as I told the tuners, I don't think I'll ever the feel the need to go beyond 350whp.

@Vermess @PoorMans180SX All tuners agree on the OEM thermostat as you both mentioned. I'm the third owner of this car in its current form and that's one of the items I didn't research when I took ownership.

MotoIQ puts out really great videos. That's really interesting about the torque plates but it makes sense. Flatirons Tuning also puts out good stuff. I'm going to ask about torque plates and whether that is necessary with a Type RA build.

Enlight

Thread starter

With the wait times for each of these shops at about 2+ months, and also sticker shock frankly, I'm beginning to think about installing this short block myself. The estimates I'm getting are $10k and up starting with the Spec RA block and then more expensive forged options. This includes all labor and upgrading supporting modifications (fuel pump, oil pump, injector conversions, etc.) and tuning. It also includes replacing parts that may have been contaminated if there was actually bearing failure. I ask that no one in this thread disparage these tuners as they have over 10 years of good reputation, I believe these estimates are based on what they feel they could confidently stand behind as far as engine longevity.

As I mentioned earlier, I've changed a clutch, replaced a fuel tank, and done a timing belt before, but I've never tore down an engine... so I do have some trepidation. That being said, there are a few people on the LegacyGT.com forums that have documented their own replacements. If I take it slowly and reference the sources available there and elsewhere, I think I can do this. I just don't want to drag this process out for months upon months (as I did my clutch). With Thanksgiving approaching, this will be the best time of year to buy parts.

As I mentioned earlier, I've changed a clutch, replaced a fuel tank, and done a timing belt before, but I've never tore down an engine... so I do have some trepidation. That being said, there are a few people on the LegacyGT.com forums that have documented their own replacements. If I take it slowly and reference the sources available there and elsewhere, I think I can do this. I just don't want to drag this process out for months upon months (as I did my clutch). With Thanksgiving approaching, this will be the best time of year to buy parts.

Enlight

Thread starter

Back towards the topic of this original thread, I have a questions for your forged experts: Do forged engines wear faster than their cast counterparts even after they have reached full operating temperature?

Enlight

Thread starter

I've committed to a rebuild path over the weekend. I was browsing Facebook Marketplace and found someone selling a never installed IAG Stage 2 TUFF short block. I paid what would amount to a 40% discount off what it MSRP's for, or about $300 more than a Spec RA block would cost from a dealer. Of course, I will not be able to take advantage of IAG's unique 2 year/24 month warranty. However, there is an IAG Gold Installer just 40 minutes from me that I will ask to do the engine assembly. I will try to save some money by performing the engine removal/installation myself, along with supporting modifications like the fuel pump, etc.

Now that I have a forged engine, I do eventually plan to install the coolant pre-heater. I will be visiting Europe in a month and will be able to purchase on cheaply and claim back the VAT tax. To keep this thread on-topic I'm going to take this conversation over to my other thread until I have an update on the pre-heater.

Now that I have a forged engine, I do eventually plan to install the coolant pre-heater. I will be visiting Europe in a month and will be able to purchase on cheaply and claim back the VAT tax. To keep this thread on-topic I'm going to take this conversation over to my other thread until I have an update on the pre-heater.

Attachments

Cue Audi "after run" systems to prevent heat soak after shutdown. Inverse intent but the overall principle is the same.

Like everything on the Type 44's (and everything Audi) it was problematic

However I will say I know of an '04 F150 with the disastrous 5.4 3V (note: the first year, too, so no "updated" parts) with 411k and has never been opened up. The owner lived in Montana and used a block heater regularly and credits the heater with prolonged engine life on several vehicles.

That said, I'm not sure how a block heater would help the problematic timing chain components in the 3V (if anything the hydraulic tensioners that blow seals would work best with cold, thick oil) but 411k and-still-going is unheard of for the 3V's. It's only a sample of one but the one outlier in this example is the block heater....so maybe there's something to it.

Like everything on the Type 44's (and everything Audi) it was problematic

However I will say I know of an '04 F150 with the disastrous 5.4 3V (note: the first year, too, so no "updated" parts) with 411k and has never been opened up. The owner lived in Montana and used a block heater regularly and credits the heater with prolonged engine life on several vehicles.

That said, I'm not sure how a block heater would help the problematic timing chain components in the 3V (if anything the hydraulic tensioners that blow seals would work best with cold, thick oil) but 411k and-still-going is unheard of for the 3V's. It's only a sample of one but the one outlier in this example is the block heater....so maybe there's something to it.

Enlight

Thread starter

That's an interesting anecdote. I tried to find info on the manufacturer for the after run system but couldn't find it. Subarus use a passive system for cooldown. The retail warmers I'm looking at have built-in safety measures but even those aren't 100%. I keep a halotron extinguisher in my car handy.

- Joined

- Aug 12, 2020

- Messages

- 167

Back towards the topic of this original thread, I have a questions for your forged experts: Do forged engines wear faster than their cast counterparts even after they have reached full operating temperature?

The short answer is no. Correct piston to wall and the pistons won't even scuff if you don't beat on it cold. Everything is basically the same as a standard engine with regards to oiling and wear.

Now, engines making more power per liter and revving higher than factory... maybe. More aggressive valvesprings and larger cams do put more pressure on the valve seats, which wears them a bit faster unless you've got really hard valves and seats. Subaru valve seats are actually exceptionally hard and long-wearing. The rings should last the same amount of time but to be honest I think that has more to do with ring material than anything and I can't say I'm intimately familiar with each manufacturer's offering in that respect. The bearings should never see wear.

I'd say more often than not it's the tune that kills forged engines, or something like a clogged injector. Otherwise they'd run for a very long time.

Similar threads

- Replies

- 96

- Views

- 18K

- Replies

- 14

- Views

- 18K

- Replies

- 9

- Views

- 7K

- Locked

- Replies

- 31

- Views

- 11K