Facts:

1981 camaro

Swap to 468

Including here- build sheet picture of some parts

History: (with some facts not realized until this week)

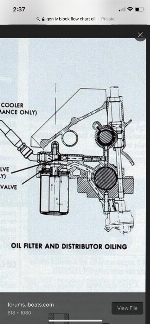

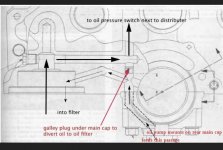

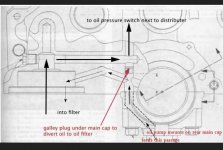

-Shop oil pressure with loop on filter adapter pegged at 80psi with priming tool.

-not sure why but temporary hose loop on adapter removed and holes plugged during installation of motor to car. Probably to gain clearance.

- loop remained off while engine controls and peripherals were installed.

-MISTAKE ONE: during ignition timing setup engine was started with blocked off adapter.

Oil pressure zero for 10 seconds at 1100rpm then rose to 45psi then erratic at 25 35 08 25

-MISTAKE TWO: after several 25 minute runs to adjust idle and timing with psi at average of 25 and changing oil and filters everything seemed within specs everyone ABSOLUTELY FORGOT ABOUT BLOCKED ADAPTER COOLER PORTS.

- (speculation)at this time oil was either breaching past small oring or possibly a bypass valve on pump according to some earlier posts.

-engine temps at idle: 190*F achieved at 5 min, 210 at 20min, 240 at 35min. Ignition turned off at 240.

-it was here in the cooling system efficiency phase that the oil cooler was connected. It was not installed earlier due to lines being unavailable at moment. And yes when it came to remember installing it, everyone had a sickening knot in their stomach and noone had the humor to even talk about the obvious elephant in the room.

-

Added oil cooler lines to sandwich adapter( inlet and outlet previously plugged).

During leak test in driveway, Oil cooler line ruptured, hose clamp on barbed fitting was loose, lost all oil, engine ran 30 seconds until I turned off ignition. Temps reached 240.

Repaired line, new oil 5w30, surprise 45 psi oil pressure reading,,,louder than normal noise from top end, turned off ignition.

My thinking was that the cooler was at fault, I wanted to go back a step to last run state of "normal" so I Removed adapter to go back to conditions prior to cooler lines, NOTICED ORING MISSING, Reinstalled adapter blocked off at ports and with new oring and with new oil filter of same brand. Turned on motor ZERO OIL PRESSURE.

Removed distributor, tried to prime pump with drill, very difficult to spin, and when finger let off drill switch, pump counter spun a half turn of the drill. Like a twisted rubber band. Ran primer in reverse thinking i could dislodge a jam in the pick up screen. Made gurgling sounds. No affect clockwise rotations were labored and few until bound up and forced a counter spin.

Note. Oil filter had oil in them but probably only on block side NOT pump side. The LAST filter after new oring was completely empty.

1981 camaro

Swap to 468

Including here- build sheet picture of some parts

History: (with some facts not realized until this week)

-Shop oil pressure with loop on filter adapter pegged at 80psi with priming tool.

-not sure why but temporary hose loop on adapter removed and holes plugged during installation of motor to car. Probably to gain clearance.

- loop remained off while engine controls and peripherals were installed.

-MISTAKE ONE: during ignition timing setup engine was started with blocked off adapter.

Oil pressure zero for 10 seconds at 1100rpm then rose to 45psi then erratic at 25 35 08 25

-MISTAKE TWO: after several 25 minute runs to adjust idle and timing with psi at average of 25 and changing oil and filters everything seemed within specs everyone ABSOLUTELY FORGOT ABOUT BLOCKED ADAPTER COOLER PORTS.

- (speculation)at this time oil was either breaching past small oring or possibly a bypass valve on pump according to some earlier posts.

-engine temps at idle: 190*F achieved at 5 min, 210 at 20min, 240 at 35min. Ignition turned off at 240.

-it was here in the cooling system efficiency phase that the oil cooler was connected. It was not installed earlier due to lines being unavailable at moment. And yes when it came to remember installing it, everyone had a sickening knot in their stomach and noone had the humor to even talk about the obvious elephant in the room.

-

Added oil cooler lines to sandwich adapter( inlet and outlet previously plugged).

During leak test in driveway, Oil cooler line ruptured, hose clamp on barbed fitting was loose, lost all oil, engine ran 30 seconds until I turned off ignition. Temps reached 240.

Repaired line, new oil 5w30, surprise 45 psi oil pressure reading,,,louder than normal noise from top end, turned off ignition.

My thinking was that the cooler was at fault, I wanted to go back a step to last run state of "normal" so I Removed adapter to go back to conditions prior to cooler lines, NOTICED ORING MISSING, Reinstalled adapter blocked off at ports and with new oring and with new oil filter of same brand. Turned on motor ZERO OIL PRESSURE.

Removed distributor, tried to prime pump with drill, very difficult to spin, and when finger let off drill switch, pump counter spun a half turn of the drill. Like a twisted rubber band. Ran primer in reverse thinking i could dislodge a jam in the pick up screen. Made gurgling sounds. No affect clockwise rotations were labored and few until bound up and forced a counter spin.

Note. Oil filter had oil in them but probably only on block side NOT pump side. The LAST filter after new oring was completely empty.