OMG. Talk about a catastrophic event. This one is going blow your minds.

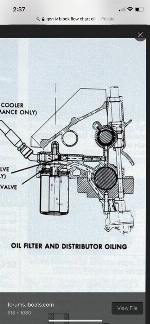

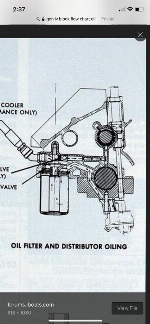

i removed oil filter sandwich adapter and discovered that the small o-ring at the top was MISSING. I included a pic of a similar one. I think when I blocked off the inlet and outlet ports to the cooler on the adapter that the oil forced its way through the small oring and sucked or pushed it into the block. So where would it have traveled and could that be in the pump? ***?

talk about a huge mistake. What could fix this besides removing oil pump???

454 gen iv moroso higg volume pump, zero oil pressure, new filter dry after using priming tool. Hard to spin pump with tool, actually reverses drill half turn when finger off switch. Running pump in reverse makes gurgling sounds in pan.

i removed oil filter sandwich adapter and discovered that the small o-ring at the top was MISSING. I included a pic of a similar one. I think when I blocked off the inlet and outlet ports to the cooler on the adapter that the oil forced its way through the small oring and sucked or pushed it into the block. So where would it have traveled and could that be in the pump? ***?

talk about a huge mistake. What could fix this besides removing oil pump???

454 gen iv moroso higg volume pump, zero oil pressure, new filter dry after using priming tool. Hard to spin pump with tool, actually reverses drill half turn when finger off switch. Running pump in reverse makes gurgling sounds in pan.