I had a buddy of replace ball joints and the camber is way out, but his machine wouldn't show camber. What ever, I'll look into it. The camber adjustment don't look right to be. All the pics on the internet show the adjustment cam on top, mine on the bottom of the upper ball joint. Is this correct?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ford Twin I beam help?

- Thread starter mpack88

- Start date

99% sure I remember the camber adjustment being at the top of the knuckle. What year is the truck?

mpack88

Thread starter

84 two wheel drive99% sure I remember the camber adjustment being at the top of the knuckle. What year is the truck?

My 94 F 150 with twin I beams has a notice cast into the beams that recommend against heating, welding , or bending the I beams. I have heard that years ago, front end alignment issues on this type front end were "corrected" with such methods.I had a buddy of replace ball joints and the camber is way out, but his machine wouldn't show camber. What ever, I'll look into it. The camber adjustment don't look right to be. All the pics on the internet show the adjustment cam on top, mine on the bottom of the upper ball joint. Is this correct?

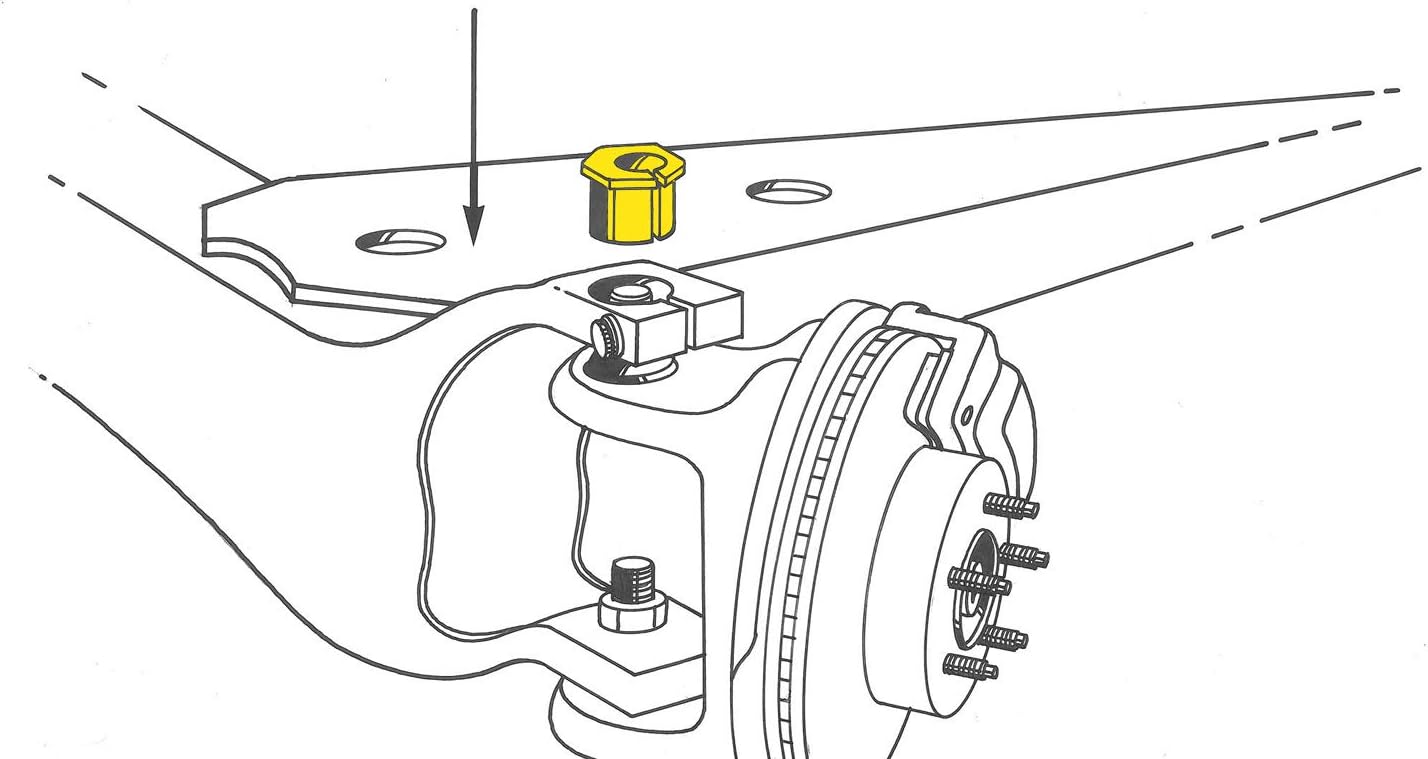

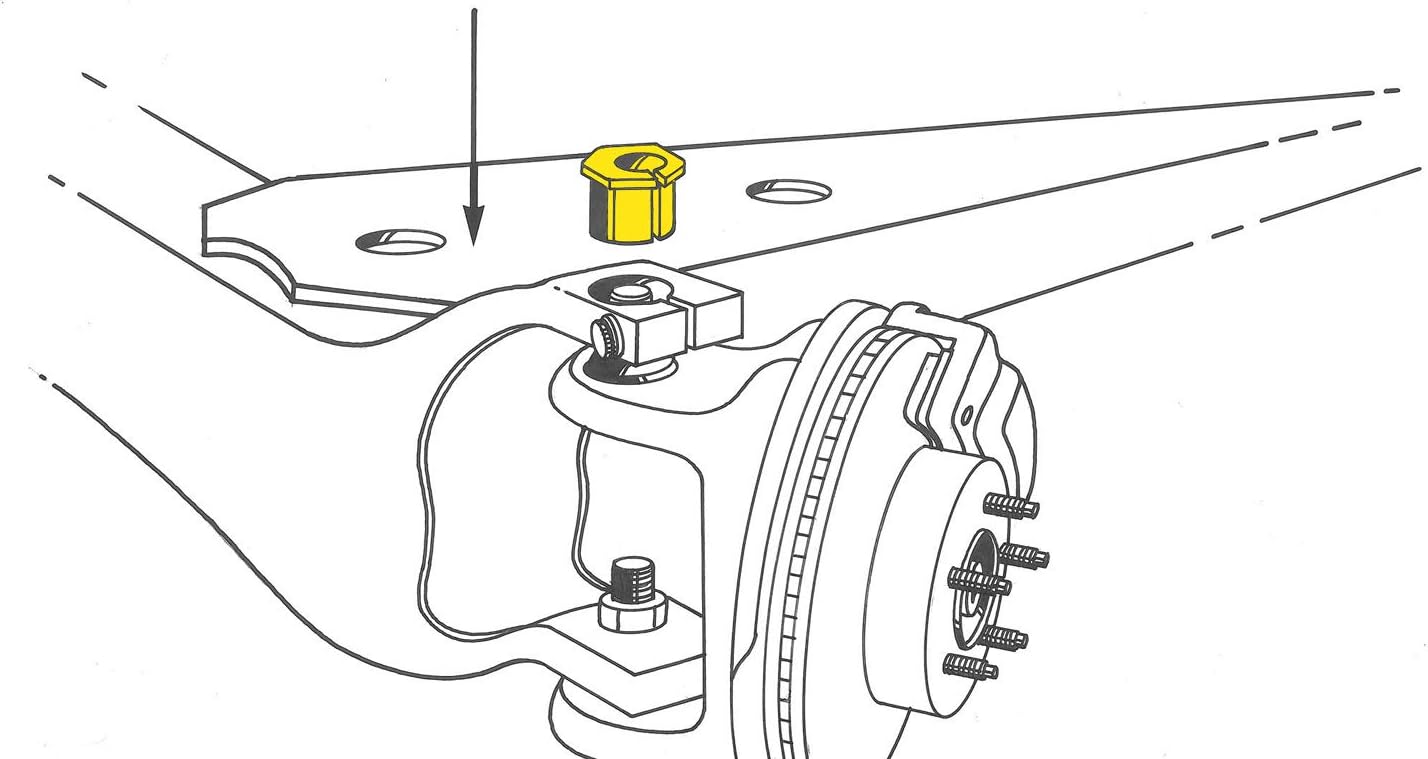

He probably didn't put the caster/camber bushings back in the same way they came out. Those are the bushings that surround the top ball joint bolt.

mpack88

Thread starter

I was assuming it was like my 3/4 ton truck where it's on the top but that's what I was talking about.

mpack88

Thread starter

I guess mine was a weird year model.I was assuming it was like my 3/4 ton truck where it's on the top but that's what I was talking about.

That pic says it's for a Ranger. Maybe that's the difference?

99-03 superdutys its on the top. my 86 f250 has kingpins - rarely wear out if greased, but when they do it's a lot of fun.

- Joined

- Apr 22, 2016

- Messages

- 1,237

The f150's have king pins that are eccentric, have fun removing them.

I recall a friend who had an 80s vintage F150 with the I-beam suspension telling me he resolved his alignment issues by replacing the rubber bushings with polyurethane. This was in the mid 80s and at the time alignment issues with this suspension type were common.

This shows a 1984 F150 which looks similar to my OBS F250. The orientation of the bushing changes the caster and camber and what you should do is mark it during disassembly so you can put it back the same way it came out. There are types that are meant to be adjustable and some that aren't. There are aftermarket kits available that can give you a wider range of adjust-ability if you can't get the alignment you need with the stock one.

Last edited:

I had an '81 F250 in the past. My recollection was exactly as the drawing above. Remove the top nut, loosen the bottom and then beat the tar out of it until it drops. I recall the adjuster at the top. Any chance your buddy put the ball joints in upside down? That would surely nuke the caster setting among other things.

I don't think there is any physically possible way to put the ball joints in upside down, but you could sure get at least some types of those caster/camber sleeve/shims in the wrong way and mess up the alignment.

Back in the '80's I worked for a Co. with a large fleet of E150's and E250's . They where supposed to load the new vans and bring them back in to get the front ends adjusted for the loads they always carried (service business) to minimize the tire wear. They never did as changing tires for them was easier than pulling a new truck out of service.

When I worked at Sears Auto we had a guy who would empty his van out of everything to bring it in for an alignment. Then come back a month or so later saying they tires were worn out. We caught on and put notes saying it was a work van that came in empty on the RO. Then finally the guy listened to someone and brought it to us fully loaded so we could get the alignment correct.Back in the '80's I worked for a Co. with a large fleet of E150's and E250's . They where supposed to load the new vans and bring them back in to get the front ends adjusted for the loads they always carried (service business) to minimize the tire wear. They never did as changing tires for them was easier than pulling a new truck out of service.

Looks to me like you have the castle nut on the top ball joint then directly behind that is a spacer that rotates in the knuckle to change the camber. the bit that the ring part of a spanner would go on. looks like a 12 sided nut.

The bring back new vans to dealer after being loaded was on Sears Service vans. Typical Sears just replacing tires all the time on the fleet.When I worked at Sears Auto we had a guy who would empty his van out of everything to bring it in for an alignment. Then come back a month or so later saying they tires were worn out. We caught on and put notes saying it was a work van that came in empty on the RO. Then finally the guy listened to someone and brought it to us fully loaded so we could get the alignment correct.

Retired tech from there after 46 yrs, I've driven a ton of makes and models there ''like I stole them" LOL

mpack88

Thread starter

Well my buddies 82 F100 is the same as mine. Camber thing on the bottom of the top ball joint. I guess for a couple of years they where made this way. Also found they make adjustable ones. I'm also going to go ahead and replace all bushings and king pins in the front end.I had an '81 F250 in the past. My recollection was exactly as the drawing above. Remove the top nut, loosen the bottom and then beat the tar out of it until it drops. I recall the adjuster at the top. Any chance your buddy put the ball joints in upside down? That would surely nuke the caster setting among other things.

Similar threads

- Replies

- 22

- Views

- 3K

- Replies

- 8

- Views

- 414

- Replies

- 25

- Views

- 1K

- Replies

- 28

- Views

- 2K