I stated that

quote:

Film strength is relational to viscosity or flow

Ok, Now I have time to go a little bit further on this subject,OK, lets follow this through.

Lets take a technical Publication Published by Texaco Inc volume 78.

Definition of Viscosity...

Viscosity, as a general concept, can be defined as the resistance of a liquid to flow or deformation. In common terms, the slower a material flows, the higher is its viscosity.

Now here's where it gets interesting...

IT IS THE VISCOSITY THAT DETERMINES THE ABILITY OF THE LUBRICANT TO MAINTAIN AN OIL FILM BETWEEN THE WORKING PARTS OF MACHINES, THE FILM THAT REDUCES FRICTION AND WEAR. Another term used is FILM STRENGTH

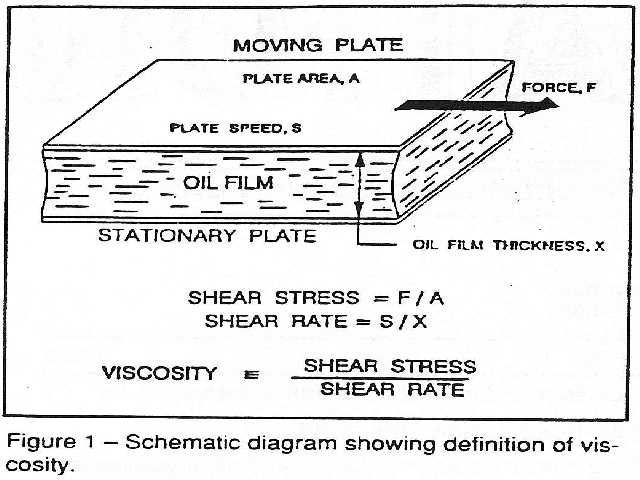

How am I doing so far? Lets include a picture that might help demonstrate this even farther...

This shows two parallel plates separated by a film of oil. The top plate is moving; the bottom is stationary. A force, indicated by the heavy arrow, must be applied to the top plate to keep it moving at a steady speed. Notice that the force is directed along the plane of the plate, not into the plate, so it is a shearing force.. Hmmmm, what bearing or cam in an engine might see this?

There are four simple measuable parameters which describe this physical situation.

- 2. The SPEED of the moving plate, S

- 3. The THICKNESS of the OIL FILM, that is, the separation between the plates, X

- 4. The FORCE required to move the plate, F

Now the interesting thing here is, do you realize that a slower moving piece of equipment will see more wear (depends on oil pressure of course), because the slower the more time for the oil to squeeze out. This is why in grease applications for example, the slower the bearing the higher the thickner, the faster, less thickner. Wow, now a picture is begining to form here, depending on the applications, a different viscosity is recommended due to the flow/shear rates which inturn creates the best wear protection. Of course to thick will detriment the effeciency but too thin will allow more wear.

Now the shear basic mechanical theory here presents itself as a very common sense approach and all through out this and many other books, film strength of an oil relates back to oil thickness or viscosity which is due to flow rate, even in bearings and gear boxes. To thin of a viscosity oil and the wear climbs, to thick performance suffers, may even retain heat more, but wear will be reduced. Don't believe it still, like Molakule mentioned earlier, why do they run a 5w

40 over there? higher viscosity = higher film strength.

So, again, we are back to the basic states of lubrication where hydrodynamic properties of an oil = film strength and hydrodynamic is the film between two surfaces which will squeeze out due to flow rate which is viscosity.

One more point, What equation is used by engineers to determine what viscosity oil to put in their equipment? Viscosity measurements or film strength measurement? Here's another one, If film strength isn't viscosity, where's the film strength measurement so you can compare between different oils????

YEP, THINKING OUT OF THE BOX, THAT IS WHAT I DO.

TERRY

Yes, it has been several years since the last time we discussed this so I have had more time to bone up on your laminar flow concept.

lets approach each one of your comments singularly...

"Synthetic" molecules can be engineered to have a more appropriate molecular structure to resist breaking from hydrodynamic to barrier lubrication"

If I recall correctly as my chemistry really stinks, the molecular structure of motor oils can come in a couple(maybe even more) ways depending on the type of oil we are discussing. somewhere between c15-20.

Hydrocarbon molecules are made of hydrogen and carbon atoms that form the basis of all petroleum, they differ in their configurations. The carbon atoms may be linked in a ring or a chain, each with a full or partial complement of hydrogen atoms. Some hydrocarbons combine easily with other materials.

Conventional motor oil is made up of an inconsistent mixture of long and short chains of carbon and hydrogen atoms. In the extreme heat of an engine, short-chain molecules can evaporate, and unstable molecules can oxidize and break down. Conventional oils used to contain much greater amounts of impurities, such as sulfur, reactive and unstable hydrocarbons, and other undesirable contaminants that were not able to be completely removed by conventional refining of crude oil but now have improved on the newer gf-3's.

Now, let's look at this, I believe you are right about one thing here, the straight chain might be more resistant to oxidation(oxygen atoms) than the hexane as this would not destroy the straight chain if an oxygen atom was to break the chain where as the hexane would be an open chain if the loop was broken. Now how would this help film stength? Guess what, I agree.. It does help the molecular film strength not the hydrodynamic film strength.

I believe I just figured out the BIG SECRET to these big boys advertising....

Lets think about this a minute.. They are not lying about better film strength, If you consider breaking down the molecular level of atoms from oxidations, the film is much higher resistant to oxygen atoms attacking the bond where as the older conventional structure would be more likely to submit to the oxygen faster therefore the film strength on the molecular level would be compromised faster.

I think many have used the defintion of film strength and assume it to mean the base oils ability to resist hydrodyamic shear when in fact it appears they are saying that it resists breakdown at the molecular level instead. I may be wrong, but this would be the only thing that makes sense to me.

In my definition of film strength, and the book I use here, This would not constitute film strength. The atomic/molecular level would not pertain to the defintion of film strength in hydrodynamic property levels.

Syns can also flow in a turbulent fashion dissipating more heat while maintaining their desired film strength. NON syns flow in a laminar fashion holding heat

Definition of lam·i·na (lm-n)

n. pl. lam·i·nae (-n) or lam·i·nas

A thin plate, sheet, or layer.

The only thing I could find on the laminar theory was where it would apply through pipes. Viscosity is very important in flud flow throught pipes. At relatively low flow rates, the flow of fluids through pipes and sucts is a smooth, orderly process, referred to as laminar flow. Under this flow condition, the pressure loss is proportional to the fluids viscosity if the other parameters are hel constant. The flow rate is inversely proportional to the viscosity.

At reativly high flow rates, the smooth, orderly flow process is disrupted and flow becomes turbulent.

Now no where is there anything that relates the molecular structure of the oil as being a part of the equation for laminar flow. The factors used in laminar flow is pipe diameter,D, the average flow velocity, V, and the kinematic viscosity, Vk,is:

Nre=Dxv/Vk. This is for newtonian fluids.

I'm not sure but from what I see, laminar effect on a fluid is measured for pipes, and has no effect according to this. Now, yeah, it might have an effect on oil in an engine but given that this is only when it is in a slow moving lubricant and the most engines are going to produce a reletively higher oil pressure than what laminar could work at there fore, again, this is not taken into effect in a engine application.

boy, I'm beat, 4am here, will look at it again later when I can see straight.

[ August 13, 2002, 07:33 PM: Message edited by: BOBISTHEOILGUY ]