Here's a previous thread on my efforts to extinguish the P0455 Large EVAP Leak code: https://bobistheoilguy.com/forums/ubbthreads.php/topics/2755714/2

I'm currently revisiting this as inspection is due. P0455 is once again illuminated + a few others related to the SAS system/blower. I was able to eliminate the later using the "diode mod". Now I can focus solely on P0455. I suspect either the canistor shut-off valve or a cracked hose on top of the gas tank. As the sled is now ~ 17yrs old and this valve has never been replaced, I'm going to do so. Pierburg makes a replacement that is about half the cost of the OEM part.

I found this detailed EVAP System description very useful:

Quote:

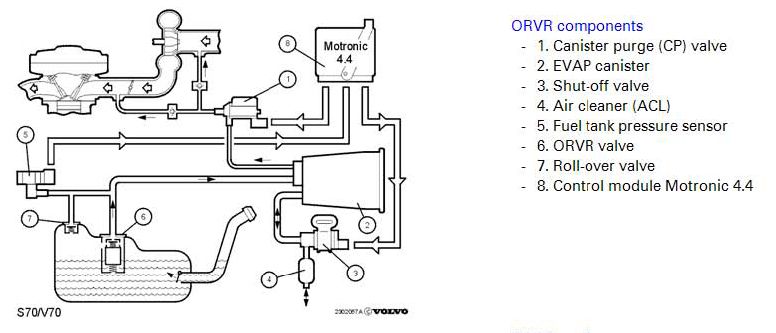

Onboard Refueling Vapor Recovery (ORVR) Components

-1. Canister purge (CP) valve

-2. EVAP canister

-3. Shut-off valve

-4. Air cleaner (ACL)

-5. Fuel tank pressure sensor

-6. ORVR valve

-7. Roll-over valve

-8. Control module Motronic 4.4

EVAP canister

Hydrocarbon vapor pressed out of the fuel tank is dealt with by the EVAP canister. To minimize pressure drop in the lines between the fuel tank and EVAP canister, the EVAP canister is located close to the fuel tank. The EVAP canister volume is 2.1 liters. A new type of carbon reduces pressure drop in the gas flowing through the EVAP canister.

ORVR valve

There is a combined float roll-over valve by the connector for the large EVAP line to the fuel tank (called the ORVR valve). As its name implies it has two functions.

-a roll-over function which closes the large EVAP line connector so that fuel cannot leak out if the car is on its side or roof.

-a float valve function which closes the large EVAP line connector when the fuel level reaches the valve when the fuel tank is full

Roll-over valve

A small EVAP line runs from the ORVR valve to a roll-over valve located as high as possible on the fuel tank. The roll-over valve ensures that the fuel tank can breath if the ORVR valve is closed when the car has been refueled.

Pressure sensor

The pressure sensor provides information about pressure in the fuel tank. The sensor is connected to a Y pipe from the ORVR valve.

The pressure sensor also obtains the fuel tank pressure via the roll-over valve if the ORVR valve is closed.

EVAP canister shut-off valve

The valve is located close to the EVAP canister. The valve is part of the leak diagnostic system and temporarily closes the EVAP canister fresh air intake during the diagnostic test.

Filter

The filter is located by the fuel filler pipe and is connected to the EVAP canister shut-off valve via a hose.

Canister purge (CP) valve

This valve controls the flow of fuel vapor and air from the EVAP canister to the engine. The valve is controlled by the engine control module (ECM).

EVAP line

The line between the EVAP canister and fuel tank has been replaced by a large 13.5 mm line.

This allows fuel vapor to move easily between the fuel tank and EVAP canister when the car is refueled.

Fuel tank filler cap

The fuel tank filler cap has a overpressure/vacuum valve.

Check valve

The check valve at the bottom of the filler pipe on cars with ORVR is the same as that on AWD cars.

System description:

When refueling starts the check valve in the fuel tank opens. The fuel flow creates negative pressure at the top of the fuel filler pipe. This results in an air flow in the fuel filler pipe. It is important to have low resistance between the fuel tank and atmospheric pressure (via the EVAP canister shut-off valve filter) to stop fuel vapor escaping from the fuel filler pipe. The principle of the system is called a dynamic seal.

When the fuel tank is full the ORVR valve closes and the fuel tank pressure increases rapidly. This closes the check valve in the fuel tank, preventing fuel coming out of the filler pipe when the fuel pump pistol is shut off.

Fuel vapor in the fuel tank (together with air) reach the EVAP canister via the ORVR valve. Fuel vapor is absorbed by the carbon in the EVAP canister. If the ORVR valve is closed the fuel tank is vented via the roll-over valve.

When the canister purge (CP) valve is closed the fuel vapor remains in the EVAP canister.

When the engine control module (ECM) transmits an opening signal to the valve, a vacuum from the intake manifold or from the fresh air intake creates a flow through the EVAP canister. The EVAP canister is connected to the outside atmosphere via the canister shut-off filter which allows the flow to evacuate the EVAP canister.

The air flow through the EVAP canister removes stored fuel vapor which flow to the engine and enter the combustion process. The canister purge (CP) valve pulses rapidly when the car is being driven and is idling.

Diagnostics are carried out as follows:

The EVAP canister shut-off valve and canister purge (CP) valve are closed and the fuel tank system is now completely closed.

Pressure in the fuel tank should be stable. If pressure drops the canister purge (CP) valve is leaking.

The EVAP canister shut-off valve opens, the tank system is open. The canister purge (CP) valve is pulsed and because of the negative pressure in the intake manifold the engine starts to suck air through the EVAP canister. Because the EVAP canister shut-off valve is open the pressure in the fuel tank drops slowly. If the pressure in the fuel tank drops rapidly the EVAP canister shut-off valve is clogged.

The EVAP canister shut-off valve is closed, the canister purge (CP) valve continued to be pulsed, pressure in the fuel tank should drop rapidly. If pressure does not drop enough there is a large leakage in the fuel tank system. A diagnostic trouble code (DTC) will be stored.

The canister purge (CP) valve is closed, the EVAP canister shut-off valve is still closed, there is negative pressure in the fuel tank.

The negative pressure (A) in the fuel tank has stabilized, if pressure starts to increase too quickly, this indicates a small leakage in the system. A diagnostic trouble code (DTC) is stored.

The EVAP canister shut-off valve opens, the EVAP function is enabled and the diagnostic test is finished.

To carry out the diagnostic:

-engine coolant temperature (ECT) is between -10OC and +107OC.

-no permanent faults stored.

-engine idling.

-speed must be 0 km/h.

-the concentration of fuel vapor in the canister must not be too high.

-there must be more than 11 liters of fuel in the tank

-the pressure in the fuel tank must not be too high.

-fuel trim must be active.

-the car must be below 2700 meters above sea level.

The diagnostic test starts at the earliest 17 minutes after the engine has been started when all conditions have been met. It takes approximately 30 seconds.

Questions:

1. Is the shut-off valve pulsed like the purge valve during driving?

2. If the shut off valve is stuck open or unable to seal, wouldn't this be an unmetered vacuum leak, and thus lower gas mileage?

Quote:

The EVAP canister shut-off valve opens, the tank system is open. The canister purge (CP) valve is pulsed and because of the negative pressure in the intake manifold the engine starts to suck air through the EVAP canister. Because the EVAP canister shut-off valve is open the pressure in the fuel tank drops slowly. If the pressure in the fuel tank drops rapidly the EVAP canister shut-off valve is clogged.

3. Why would the fuel tank pressure drop slowly if the EVAP canister shut-off valve is open? I would think it would quickly equalize to atmospheric pressure?

4. How could the pressure in the fuel tank drop rapidly if the EVAP canister shut-off valve is clogged?

5. In a properly functioning system (ie no vacuum leaks), should air be drawn into the fuel tank when the gas cap is loosened (WHOOOSH) before filling up? No air is drawn into an empty tank when I do this. If this system is designed to be sealed, and engine vacuum is pulled constantly on the tank vent system when the engine is on, shouldn't there be a WHOOOSH when the cap is loosened when the engine is turned off?

OR

Is this tank vacuum released when the engine is turned off because the ECU opens the shut-off valve, thus air is drawn into the air filter, through the valve, through the carbon canistor and into the tank, immediately upon ignition turn-off?

I'm currently revisiting this as inspection is due. P0455 is once again illuminated + a few others related to the SAS system/blower. I was able to eliminate the later using the "diode mod". Now I can focus solely on P0455. I suspect either the canistor shut-off valve or a cracked hose on top of the gas tank. As the sled is now ~ 17yrs old and this valve has never been replaced, I'm going to do so. Pierburg makes a replacement that is about half the cost of the OEM part.

I found this detailed EVAP System description very useful:

Quote:

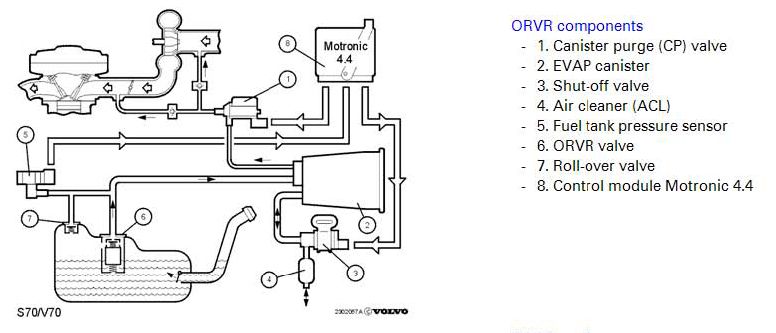

Onboard Refueling Vapor Recovery (ORVR) Components

-1. Canister purge (CP) valve

-2. EVAP canister

-3. Shut-off valve

-4. Air cleaner (ACL)

-5. Fuel tank pressure sensor

-6. ORVR valve

-7. Roll-over valve

-8. Control module Motronic 4.4

EVAP canister

Hydrocarbon vapor pressed out of the fuel tank is dealt with by the EVAP canister. To minimize pressure drop in the lines between the fuel tank and EVAP canister, the EVAP canister is located close to the fuel tank. The EVAP canister volume is 2.1 liters. A new type of carbon reduces pressure drop in the gas flowing through the EVAP canister.

ORVR valve

There is a combined float roll-over valve by the connector for the large EVAP line to the fuel tank (called the ORVR valve). As its name implies it has two functions.

-a roll-over function which closes the large EVAP line connector so that fuel cannot leak out if the car is on its side or roof.

-a float valve function which closes the large EVAP line connector when the fuel level reaches the valve when the fuel tank is full

Roll-over valve

A small EVAP line runs from the ORVR valve to a roll-over valve located as high as possible on the fuel tank. The roll-over valve ensures that the fuel tank can breath if the ORVR valve is closed when the car has been refueled.

Pressure sensor

The pressure sensor provides information about pressure in the fuel tank. The sensor is connected to a Y pipe from the ORVR valve.

The pressure sensor also obtains the fuel tank pressure via the roll-over valve if the ORVR valve is closed.

EVAP canister shut-off valve

The valve is located close to the EVAP canister. The valve is part of the leak diagnostic system and temporarily closes the EVAP canister fresh air intake during the diagnostic test.

Filter

The filter is located by the fuel filler pipe and is connected to the EVAP canister shut-off valve via a hose.

Canister purge (CP) valve

This valve controls the flow of fuel vapor and air from the EVAP canister to the engine. The valve is controlled by the engine control module (ECM).

EVAP line

The line between the EVAP canister and fuel tank has been replaced by a large 13.5 mm line.

This allows fuel vapor to move easily between the fuel tank and EVAP canister when the car is refueled.

Fuel tank filler cap

The fuel tank filler cap has a overpressure/vacuum valve.

Check valve

The check valve at the bottom of the filler pipe on cars with ORVR is the same as that on AWD cars.

System description:

When refueling starts the check valve in the fuel tank opens. The fuel flow creates negative pressure at the top of the fuel filler pipe. This results in an air flow in the fuel filler pipe. It is important to have low resistance between the fuel tank and atmospheric pressure (via the EVAP canister shut-off valve filter) to stop fuel vapor escaping from the fuel filler pipe. The principle of the system is called a dynamic seal.

When the fuel tank is full the ORVR valve closes and the fuel tank pressure increases rapidly. This closes the check valve in the fuel tank, preventing fuel coming out of the filler pipe when the fuel pump pistol is shut off.

Fuel vapor in the fuel tank (together with air) reach the EVAP canister via the ORVR valve. Fuel vapor is absorbed by the carbon in the EVAP canister. If the ORVR valve is closed the fuel tank is vented via the roll-over valve.

When the canister purge (CP) valve is closed the fuel vapor remains in the EVAP canister.

When the engine control module (ECM) transmits an opening signal to the valve, a vacuum from the intake manifold or from the fresh air intake creates a flow through the EVAP canister. The EVAP canister is connected to the outside atmosphere via the canister shut-off filter which allows the flow to evacuate the EVAP canister.

The air flow through the EVAP canister removes stored fuel vapor which flow to the engine and enter the combustion process. The canister purge (CP) valve pulses rapidly when the car is being driven and is idling.

Diagnostics are carried out as follows:

The EVAP canister shut-off valve and canister purge (CP) valve are closed and the fuel tank system is now completely closed.

Pressure in the fuel tank should be stable. If pressure drops the canister purge (CP) valve is leaking.

The EVAP canister shut-off valve opens, the tank system is open. The canister purge (CP) valve is pulsed and because of the negative pressure in the intake manifold the engine starts to suck air through the EVAP canister. Because the EVAP canister shut-off valve is open the pressure in the fuel tank drops slowly. If the pressure in the fuel tank drops rapidly the EVAP canister shut-off valve is clogged.

The EVAP canister shut-off valve is closed, the canister purge (CP) valve continued to be pulsed, pressure in the fuel tank should drop rapidly. If pressure does not drop enough there is a large leakage in the fuel tank system. A diagnostic trouble code (DTC) will be stored.

The canister purge (CP) valve is closed, the EVAP canister shut-off valve is still closed, there is negative pressure in the fuel tank.

The negative pressure (A) in the fuel tank has stabilized, if pressure starts to increase too quickly, this indicates a small leakage in the system. A diagnostic trouble code (DTC) is stored.

The EVAP canister shut-off valve opens, the EVAP function is enabled and the diagnostic test is finished.

To carry out the diagnostic:

-engine coolant temperature (ECT) is between -10OC and +107OC.

-no permanent faults stored.

-engine idling.

-speed must be 0 km/h.

-the concentration of fuel vapor in the canister must not be too high.

-there must be more than 11 liters of fuel in the tank

-the pressure in the fuel tank must not be too high.

-fuel trim must be active.

-the car must be below 2700 meters above sea level.

The diagnostic test starts at the earliest 17 minutes after the engine has been started when all conditions have been met. It takes approximately 30 seconds.

Questions:

1. Is the shut-off valve pulsed like the purge valve during driving?

2. If the shut off valve is stuck open or unable to seal, wouldn't this be an unmetered vacuum leak, and thus lower gas mileage?

Quote:

The EVAP canister shut-off valve opens, the tank system is open. The canister purge (CP) valve is pulsed and because of the negative pressure in the intake manifold the engine starts to suck air through the EVAP canister. Because the EVAP canister shut-off valve is open the pressure in the fuel tank drops slowly. If the pressure in the fuel tank drops rapidly the EVAP canister shut-off valve is clogged.

3. Why would the fuel tank pressure drop slowly if the EVAP canister shut-off valve is open? I would think it would quickly equalize to atmospheric pressure?

4. How could the pressure in the fuel tank drop rapidly if the EVAP canister shut-off valve is clogged?

5. In a properly functioning system (ie no vacuum leaks), should air be drawn into the fuel tank when the gas cap is loosened (WHOOOSH) before filling up? No air is drawn into an empty tank when I do this. If this system is designed to be sealed, and engine vacuum is pulled constantly on the tank vent system when the engine is on, shouldn't there be a WHOOOSH when the cap is loosened when the engine is turned off?

OR

Is this tank vacuum released when the engine is turned off because the ECU opens the shut-off valve, thus air is drawn into the air filter, through the valve, through the carbon canistor and into the tank, immediately upon ignition turn-off?