I was wondering, is there anything to gain from using a C3 oil instead of A3/B3/B4 in a standard non direction injection gasoline engine without a DPF? Is there an area where it can do better, like engine cleanliness or are top of line full saps euro synthetics just as good in every regard? Let's say we're comparing a C3, MB 229.51 5w40 to an A3/B4, MB 229.5 5w40.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Benefits of a mid saps oil in a standard gas engine?

- Thread starter OM605

- Start date

Not really. If burning a bit of oil it could help with preservation of catalytic converter.I was wondering, is there anything to gain from using a C3 oil instead of A3/B3/B4 in a standard non direction injection gasoline engine without a DPF? Is there an area where it can do better, like engine cleanliness or are top of line full saps euro synthetics just as good in every regard? Let's say we're comparing a C3, MB 229.51 5w40 to an A3/B4, MB 229.5 5w40.

The main difference between 229.5 and 229.51 must be the type of antiwear additives used and to me the heart of the question is which provides better protection. I wish I knew the answer.

OP, I’ve thought the same question myself. None of my cars are DI, yet the trend is towards lower SAPS oils.

Also fuel quality (low sulphur) has improved significantly over the years allowing the use of low SAPS oils. Europe and Japan are down to 10 ppm max Sulphur. Australia in the bad old days was 500 ppm sulphur, now regular fuel (91 RON) is limited to 150 ppm, with premium fuel (95 & 98 RON) at 50 ppm and diesel at 10ppm.

Australian petrol (gas) is planned to go to 10ppm Sulphur in 2027. Back in 2001 petrol and diesel were both at 500ppm.

To me, the longer the oil change interval (oci) and the higher the level of Sulphur in the fuel, then the higher the SAPS level required in the engine oil (for TBN to fight acid contamination from the sulphur).

Right now with my port injected cars, I’m running high SAPS A3/B4 oils. I could probably extend my OCI from 6000 miles to 10,000 miles, but I don’t see the need to push it.

Also fuel quality (low sulphur) has improved significantly over the years allowing the use of low SAPS oils. Europe and Japan are down to 10 ppm max Sulphur. Australia in the bad old days was 500 ppm sulphur, now regular fuel (91 RON) is limited to 150 ppm, with premium fuel (95 & 98 RON) at 50 ppm and diesel at 10ppm.

Australian petrol (gas) is planned to go to 10ppm Sulphur in 2027. Back in 2001 petrol and diesel were both at 500ppm.

To me, the longer the oil change interval (oci) and the higher the level of Sulphur in the fuel, then the higher the SAPS level required in the engine oil (for TBN to fight acid contamination from the sulphur).

Right now with my port injected cars, I’m running high SAPS A3/B4 oils. I could probably extend my OCI from 6000 miles to 10,000 miles, but I don’t see the need to push it.

fuel dilution is a good way to get sulfur in the oil aswell... first signs I get that a DI engine haqs injector issues is broken down oil on the disptick and inside the oil filler neck. Low or mid-saps isn't helping any with that.

Only use grade recommended in the owners manual+latest upgrade ..e.g.-ILSAC 6a, API SP, Dexron VI etc. etc.I was wondering, is there anything to gain from using a C3 oil instead of A3/B3/B4 in a standard non direction injection gasoline engine without a DPF? Is there an area where it can do better, like engine cleanliness or are top of line full saps euro synthetics just as good in every regard? Let's say we're comparing a C3, MB 229.51 5w40 to an A3/B4, MB 229.5 5w40.

The requirement for my engine back in the day was something like API SH and ACEA A2/B2. Basically any oil will do to some extend, i just limit my choice to 3.5+ HTHS oils.Only use grade recommended in the owners manual+latest upgrade ..e.g.-ILSAC 6a, API SP, Dexron VI etc. etc.

- Joined

- Feb 11, 2021

- Messages

- 80

These two things are so functionally similar, my advice would be to always buy the cheaper option.

However there's something here worth highlighting.

Perhaps the most significant aspect of the C3 spec is the 0.3% max Sulphur spec. I never liked it & I still don't. 0.3% max sulphur basically accounts for the sulphur in your ZDDP as limited by the 950 ppm max Phosphorus spec. However there are other sources of sulphur such as detergents (Sulphonates & Phenates) & antioxidants (Molybdenum Di-THIO Phosphate & sulphurised olefins). All of the above are routinely found in A3/B3/B4 oils but because the sulphur spec is so tight, these tend to be 'squeezed out' of C3 oils.

This is especially true of detergents where traditional sulphonates & phenates have been forced out by sulphur-free Salicylates & Calixarates. This has implications. Not only are these more expensive to make but you need a lot more of them. To put 6 TBN into an oil, you'll need 2% of 300 TBN Calcium Sulphonate but close to 4% of Calcium Salicylate! (remember, you always end up paying for this). And these detergents aren't actually that good. They are brilliant in ship engines burning Bunker C fuel oil & IMHO, that where they should have always stayed.

Of course there's a formulatory dodge you can deploy to get around this which is to deliberately drop your ZDDP level to create headroom but why would any sane person do that?

The 0.3% spec is plain wrong. The Americans seem to manage quite happily with 0.5% max. TBH, even a 0.35% spec would be livable with. I always wondered where the 0.3% spec came from & how much undue influence was brought to bear by those parties with most to benefit from such a restrictive move??

However there's something here worth highlighting.

Perhaps the most significant aspect of the C3 spec is the 0.3% max Sulphur spec. I never liked it & I still don't. 0.3% max sulphur basically accounts for the sulphur in your ZDDP as limited by the 950 ppm max Phosphorus spec. However there are other sources of sulphur such as detergents (Sulphonates & Phenates) & antioxidants (Molybdenum Di-THIO Phosphate & sulphurised olefins). All of the above are routinely found in A3/B3/B4 oils but because the sulphur spec is so tight, these tend to be 'squeezed out' of C3 oils.

This is especially true of detergents where traditional sulphonates & phenates have been forced out by sulphur-free Salicylates & Calixarates. This has implications. Not only are these more expensive to make but you need a lot more of them. To put 6 TBN into an oil, you'll need 2% of 300 TBN Calcium Sulphonate but close to 4% of Calcium Salicylate! (remember, you always end up paying for this). And these detergents aren't actually that good. They are brilliant in ship engines burning Bunker C fuel oil & IMHO, that where they should have always stayed.

Of course there's a formulatory dodge you can deploy to get around this which is to deliberately drop your ZDDP level to create headroom but why would any sane person do that?

The 0.3% spec is plain wrong. The Americans seem to manage quite happily with 0.5% max. TBH, even a 0.35% spec would be livable with. I always wondered where the 0.3% spec came from & how much undue influence was brought to bear by those parties with most to benefit from such a restrictive move??

Brilliant post, thank you!However there's something here worth highlighting.

I think that is what Penzoil US (Shell) does?Of course there's a formulatory dodge you can deploy to get around this which is to deliberately drop your ZDDP level to create headroom but why would any sane person do that?

The tradeoff with low saps is increased wear.

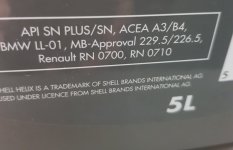

Currently using this and it's been great. Also understand that GTL base has the lowest NOACK evaporation losses. This is very important IMO for hot running / oil destroying T-GDI engines.

Currently using this and it's been great. Also understand that GTL base has the lowest NOACK evaporation losses. This is very important IMO for hot running / oil destroying T-GDI engines.

Attachments

Last edited:

I don’t think so... Redline and Ravenol aren’t GTL based from what I know and they have some of the lowest NOACK around. I could be mistaken though. Also 229.5 specs must have NOACK of 10% or less per MB standards. So it’s not just GTL, it’s other base stocks and specifications too. However the oil you posted is good stuff.The tradeoff with low saps is increased wear.

Currently using this and it's been great. Also understand that GTL base has the lowest NOACK evaporation losses. This is very important IMO for hot running / oil destroying T-GDI engines.

GTL performance characteristics are almost 100% identical with PAO. While outpacing PAO in seal conditioning and additive compatibility. Which are very important considerations.I don’t think so... Redline and Ravenol aren’t GTL based from what I know and they have some of the lowest NOACK around. I could be mistaken though. Also 229.5 specs must have NOACK of 10% or less per MB standards. So it’s not just GTL, it’s other base stocks and specifications too. However the oil you posted is good stuff.

...

except GTL only exists in 1 or 2 viscosities... very thin ones at that.GTL performance characteristics are almost 100% identical with PAO. While outpacing PAO in seal conditioning and additive compatibility. Which are very important considerations.

Outpacing PAO in seal conditioning and additive capability? Do you have proof to back that statement and by that I mean scientific research/proof/tests. Both are great don't get me wrong. Besides Shell pissed a lot of money on that GTL plant in Qatar if they don't use that GTL narrative no one else will.GTL performance characteristics are almost 100% identical with PAO. While outpacing PAO in seal conditioning and additive compatibility. Which are very important considerations.

Since GTL is more like a GIII+ and Grp III is known to play a bit better with additives and seals, it seems a reasonable enough claim.

These two things are so functionally similar, my advice would be to always buy the cheaper option.

However there's something here worth highlighting.

Perhaps the most significant aspect of the C3 spec is the 0.3% max Sulphur spec. I never liked it & I still don't. 0.3% max sulphur basically accounts for the sulphur in your ZDDP as limited by the 950 ppm max Phosphorus spec. However there are other sources of sulphur such as detergents (Sulphonates & Phenates) & antioxidants (Molybdenum Di-THIO Phosphate & sulphurised olefins). All of the above are routinely found in A3/B3/B4 oils but because the sulphur spec is so tight, these tend to be 'squeezed out' of C3 oils.

This is especially true of detergents where traditional sulphonates & phenates have been forced out by sulphur-free Salicylates & Calixarates. This has implications. Not only are these more expensive to make but you need a lot more of them. To put 6 TBN into an oil, you'll need 2% of 300 TBN Calcium Sulphonate but close to 4% of Calcium Salicylate! (remember, you always end up paying for this). And these detergents aren't actually that good. They are brilliant in ship engines burning Bunker C fuel oil & IMHO, that where they should have always stayed.

Of course there's a formulatory dodge you can deploy to get around this which is to deliberately drop your ZDDP level to create headroom but why would any sane person do that?

The 0.3% spec is plain wrong. The Americans seem to manage quite happily with 0.5% max. TBH, even a 0.35% spec would be livable with. I always wondered where the 0.3% spec came from & how much undue influence was brought to bear by those parties with most to benefit from such a restrictive move??

Out of curiosity then, in an application with a Euro 6 diesel engine eqquipt with a DPF, what would you reccomend? Are you better off looking at HDEO's? Maybe something that carries an ACEA E6/E9 specification?

He isn’t going to reply because he’s been banned.Out of curiosity then, in an application with a Euro 6 diesel engine eqquipt with a DPF, what would you reccomend? Are you better off looking at HDEO's? Maybe something that carries an ACEA E6/E9 specification?

No doubt PAO reigns supreme when it comes to extreme oxidative stability, low volatility and high VI.Outpacing PAO in seal conditioning and additive capability? Do you have proof to back that statement and by that I mean scientific research/proof/tests. Both are great don't get me wrong. Besides Shell pissed a lot of money on that GTL plant in Qatar if they don't use that GTL narrative no one else will.

However the general consensus is that GTL performance is very close to PAO while being better at protecting seals and also better at mixing with additives.

The pearl plant in Qatar is a joint venture with the government and Shell wouldhave access to the gas free of charge.

Joint venture doesn’t mean freebies. On Wikipedia (not the most reliable) it says they have free input gas, not sure what that means. I’m sure they have to pay certain fees/possible taxes etc. Related party transactions have carrying and exchange values which do affect financial statements per IFRS, so you can’t say free of charge. But we are talking accounting now not oil.No doubt PAO reigns supreme when it comes to extreme oxidative stability, low volatility and high VI.

However the general consensus is that GTL performance is very close to PAO while being better at protecting seals and also better at mixing with additives.

The pearl plant in Qatar is a joint venture with the government and Shell wouldhave access to the gas free of charge.

I doubt Qatar paid for the plant out of their pocket. It was Shell. Maybe they subsidized it? Before even putting drill to sediment they put paper to pen and probably used a discounted cash flow model to determine the NPV for the plant itself.

I still haven’t been provided any sources of academic research or tests which prove GTL > PAO or is equal to it. Do I doubt it? No. But facts don’t care about my gut feelings and it would be nice to see.

Last edited:

Similar threads

- Replies

- 52

- Views

- 3K

- Replies

- 19

- Views

- 2K

- Replies

- 20

- Views

- 4K

- Replies

- 13

- Views

- 4K

- Replies

- 16

- Views

- 752